Field Service Engineer in Packaging Manufacturing – an exciting industry

What is it like to work as a Field Service Engineer in Packaging Manufacturing?

Michael Onwukwe has experience in field service engineering and project management in the packaging manufacturing industry. He has worked in Africa and India on different projects.

Michael has worked for miho Inspektionssysteme GmbH and he currently works for SIG Group and has recently won two awards. He was awarded “Employee of The Month” for the month of February 2025. Also, with the support of his Sub-Saharan team again, he was selected for the regional IMEA (India/Middle East/Africa) “FSE Rise Award” for the month of August 2025.

Giving the most and being innovative in Packaging Manufacturing

Background

Were you interested in how things worked when you were a child? Can you give examples?

Yes. I was so keen to know how belt conveyors went round.

When I was eleven and twelve years old, this led me to watching my dad closely each time he and his workers were joining belt conveyors (endless joining) in his workshop for his clients (mainly construction and food (who use packaging manufacturing) companies).

What is the earliest thing you can remember fixing or taking apart?

I remember taking apart a torch and a packet radio.

Has there been a particular person (or people) who inspired you? and why?

I have a lot of people that inspired and are still inspiring me now. However, my dad and my Ghanaian teachers while I was at school in the city of Ibadan will take the lead because they moulded my value system and my technical acumen as a child.

Why did you decide to study engineering?

I decided to study engineering because first hand, I saw how my dad’s technical skill set was sought after within the industries which were then in Nigeria. Later, my strength at further mathematics, physics and chemistry gave me the nod and encouragement to go for engineering as a field of study.

Starting work after an engineering degree

You have been successful in working in different roles for different companies. What is your advice for someone studying engineering now in how to prepare for the job market?

My advice for anyone studying engineering now is to go for internships, either voluntary or paid while they are still studying. This helps them integrate well into the job market, because the market needs men/women with great technical skills.

Why do you think internships are important?

Internships create confidence that supplements the theoretical knowledge gained from classes. Basically, it’s the linking bridge between class and the field.

You worked for Fenner Group (now known as Fenner Precision Polymers) and Fumman Agricultural Products plc while you were studying. What skills did each of these internships give you (hard and soft)?

Actually, I interned with these two firms. The first internship was after my secondary school in Ibadan before I got into university. While the second internship was during my undergraduate days at Nnamdi Azikiwe University, Awka.

During these two internships, I learnt a lot of hard and soft skills which includes logical and schematic troubleshooting skills, communication skills, and automation knowledge.

Working on packaging manufacturing and bottling equipment

What are the different types of packaging manufacturing equipment you have worked on? (serviced, maintained, and installed)?

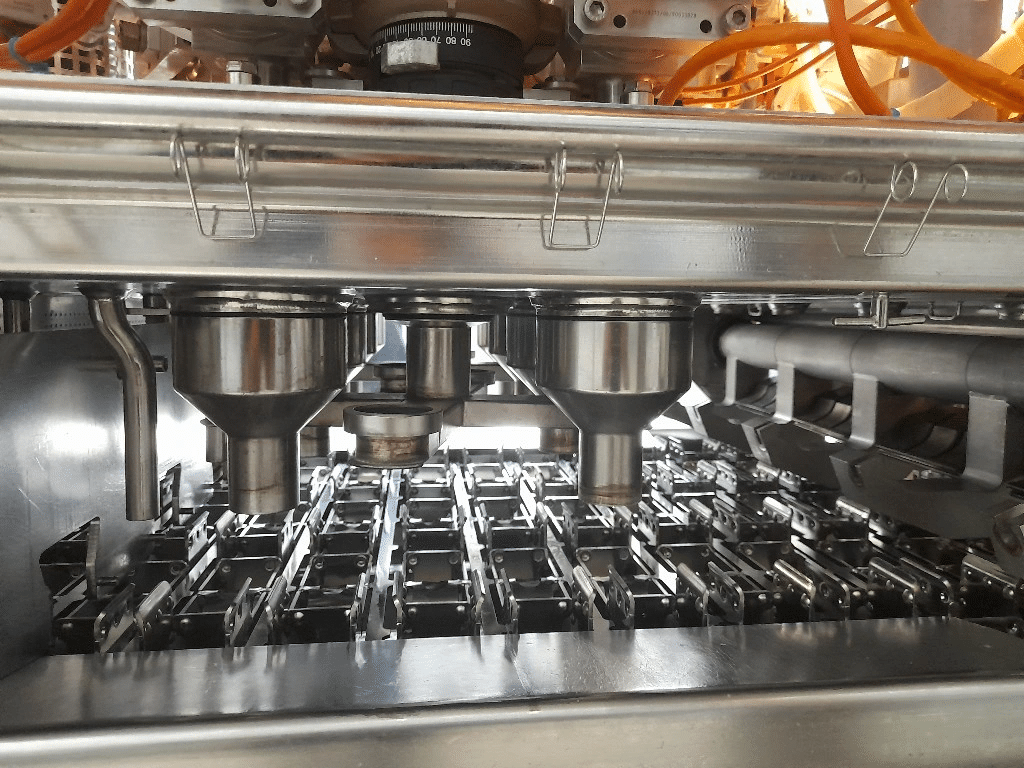

Boullion cube, Bottling, and Aseptic Carton packaging equipment.

How did your skills transfer from one type of packaging manufacturing equipment to another?

Machines generally work on some generic electrical and mechanical principles. The basic thing to know in addition is to understand how the machine works (principle of operation). The rest depends solely on one’s ability to read and understand schematics and mechanical drawings.

These two generic principles I stated earlier are easily transferable on any equipment whatsoever.

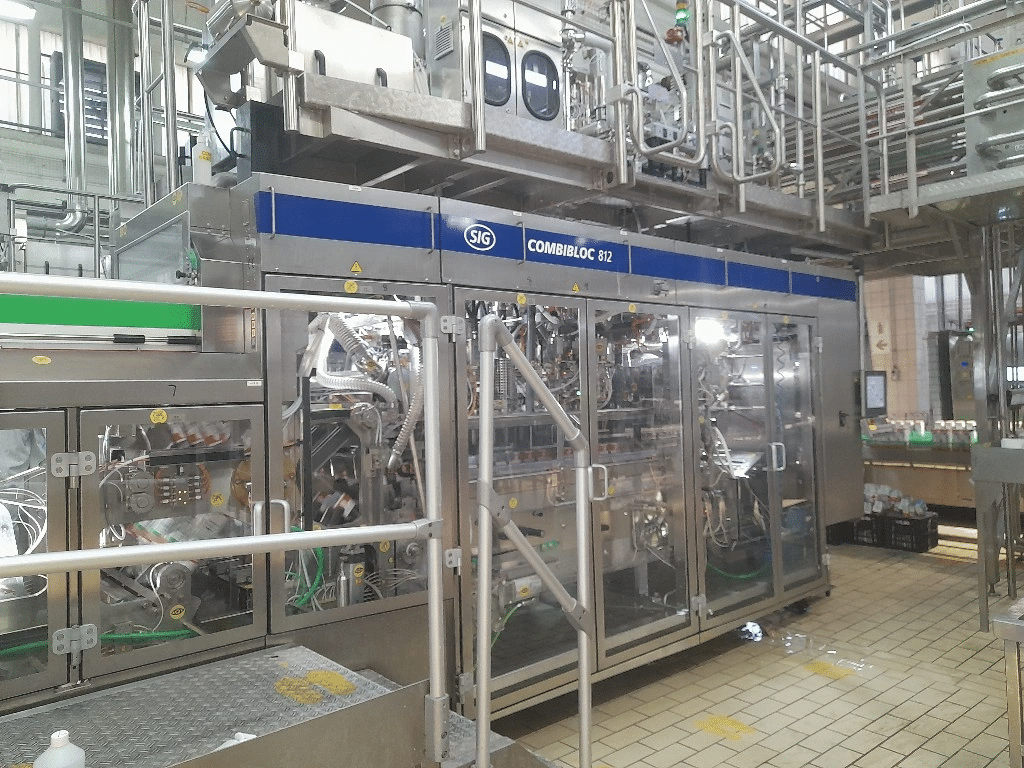

Working at SIG Group as a Field Service Engineer for Packaging Manufacturing Equipment

Your role covers India, the Middle East and Africa (IMEA and SSA), can you describe a typical packaging manufacturing installation and commissioning project?

A typical successful installation and commissioning project starts from a successful equipment FAT (Factory Acceptance Test), to smooth logistics (this ensures that no part of the equipment is damaged during transportation), to deploying the appropriate personnel (mechanical, electrical, automation, project managers, and quality assurance specialists) for installation and commissioning.

Packaging manufacturing installation involves coupling different machines on the line via conveyors, aligning conveyor heights, pipe connections, electrical connections, and testing/powering.

Commissioning involves inputting standardised parameters on the packaging and manufacturing machine according to readings taken on-spot or organizational SOPs by the commissioning engineer(s) and confirmation by the quality specialist on-site. These quality specialists make sure that these parameters are within the specifications of regulatory bodies before final commercial production run.

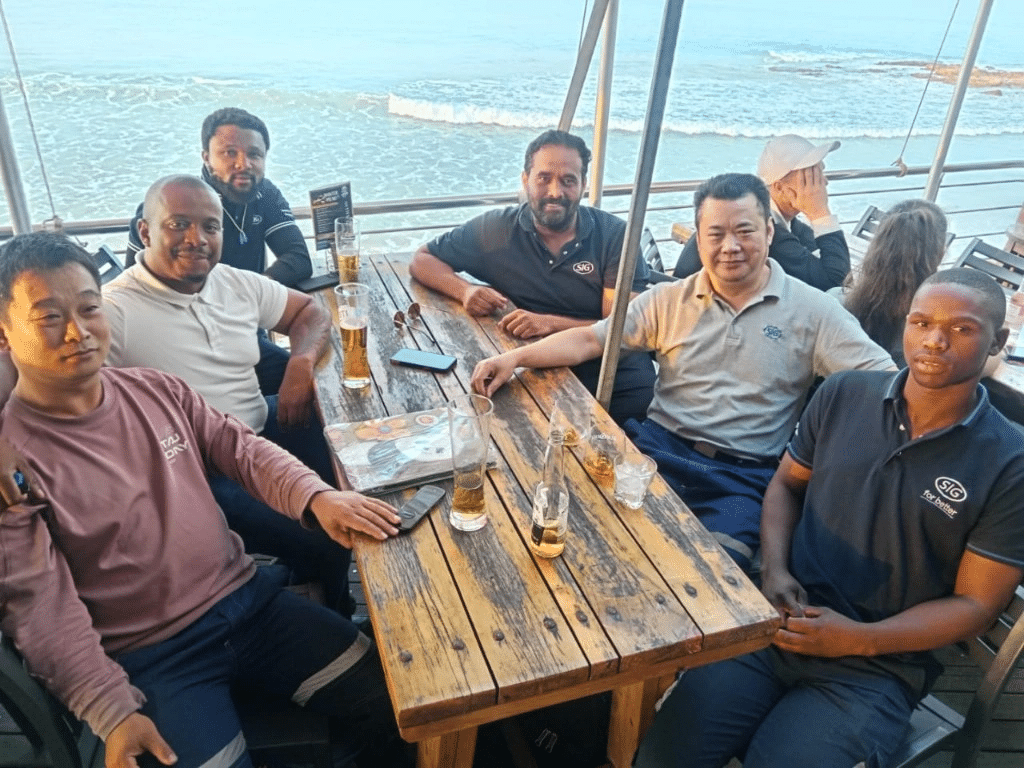

During an installation of packaging manufacturing equipment, how many different people do you work with? How do you successfully work with other cultures?

I work with many people from different countries and different cultural backgrounds. I work successfully with other cultures by:

getting to bond with them after daily work over some bottles of wine and some site visitations;

learning their basic greetings;

and also having humility to learn and share knowledge with them.

How much of your time is spent on site with the packaging manufacturing equipment and how much with admin and other tasks?

80% of my time is spent on site and about 20% on administrative tasks.

Which other parts of the organisation give you support?

Technical and Sales departments.

How do you ensure that everyone always follows health and safety procedures? (How do you convince them of the importance of these things?)

By acting safely and letting my team know that safety is everyone’s responsibility. Our families need us back home in the same condition that we left our homes.

How do you explain technical issues to non-technical people? Can you give examples?

For me, the best way to explain technical issues to non-technical people is to let them see how those things work. In a case where they can’t see, I resort to using diagrams and probably videos to explain quicker and better.

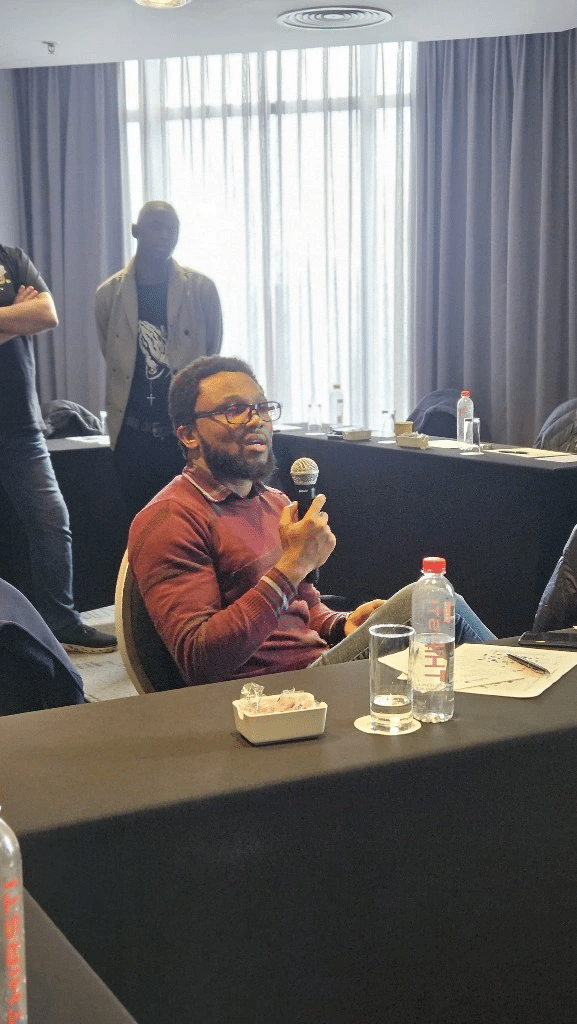

Awards

You have recently won some awards for your work on packaging manufacturing equipment. Can you give details?

Yes, I received some awards recently from SIG Group. So, with the support of everyone in my cluster (Sub-Saharan Cluster), I was awarded “Employee of The Month” for the month of February 2025. Also with the support of my Sub-Saharan team again, I was selected for the regional IMEA (India/Middle East/Africa) “FSE Rise Award” for the month of August 2025.

Why do you think awards are important in an engineer’s career?

Generally awards are very important. They are also a source of motivation.

Making a winner

What makes the type of field service engineer who is tomorrow’s lead engineer?

Leadership skills that encompass excellent technical and communication skills, conflict management skills, some financial knowledge, and excellent knowledge transfer skills make a typical lead engineer for tomorrow.

How important are communication and people skills?

Very important, no doubt at all about that.

How important is ongoing training?

Very important also. If any organisation wants the best results, they need to invest in training and re-training.

Field Service Engineers also need to make continuous improvements personally. For example, get certified by relevant bodies, take on personal training and also lean towards management studies, because engineers are good managers.

In your opinion, can a good engineer adapt to working on any type of equipment and in any industry?

Yes, a good engineer should be able to adapt to working on any equipment and in any industry. The engineer is already skilled, the business or organisation just need to send the engineer on a tailored training (intensive and extensive), to deliver the needed results for the business.

Further reading about packaging manufacturing equipment

How to maintain successful bottling production equipment

Life of a Field Service Engineer who loves Italian technology

Responses