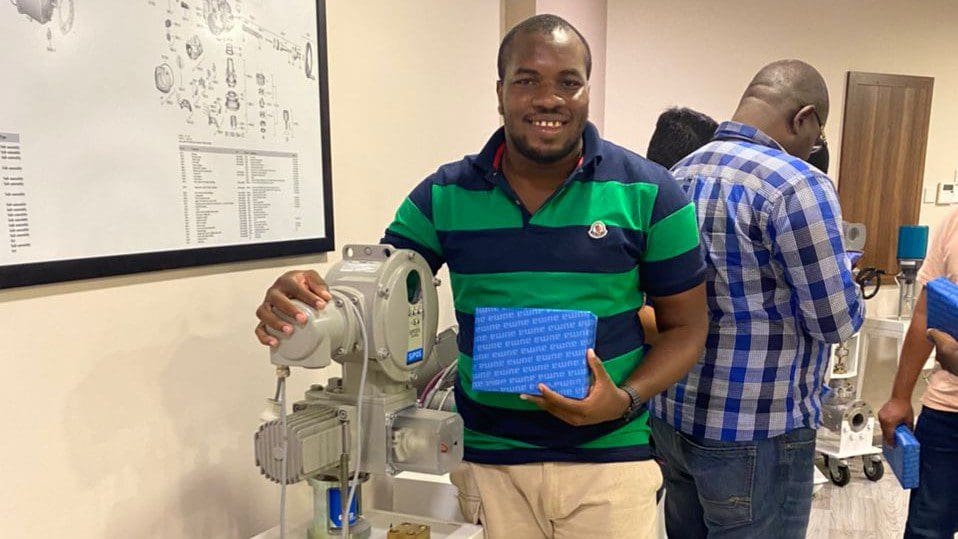

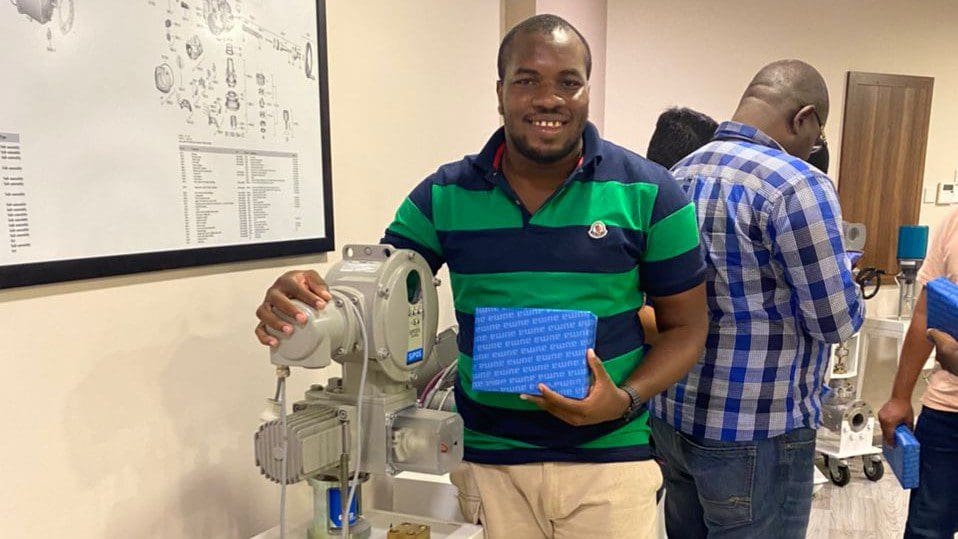

An Instrumentation Engineer keeping the production line running

This article looks at the work of an instrumentation service engineer keeping the production line running. From initial customer interaction and needs assessment to technical proposal preparation, project supervision, and post-implementation support. Meet Francis Onukwufor who shares his career and experience.

One Instrumentation Service Engineer’s experience working on a production line

Background and path to engineering

Did science, engineering and the way things work interest you as a child?

As a child, my fascination with science and engineering was deeply inspired by the world of science fiction. Watching those movies opened my eyes to a world where ground-breaking engineering solutions were a reality. The way they portrayed a highly advanced and futuristic world intrigued me and sparked my curiosity about what could be achieved through innovation. It was this early exposure that ultimately drove me to study engineering, aspiring to be a part of the real-world advancements that were once only dreams on the silver screen.

Did you fix or make things when you were a child? Or help someone with practical tasks?

I had a knack for disassembling electronic devices. In addition, I found immense satisfaction in exploring the inner workings of phones, computers, and other gadgets. I vividly remember interacting with these devices, almost as if having conversations with them to achieve specific outcomes.

Interestingly, this early interest in understanding technology and communication with machines has translated into my current work. Just as in those days, I now engage with machines, comprehending their functionalities to ensure they function seamlessly.

It’s intriguing to witness how my childhood curiosity has blossomed into a career centred around technology and intricate systems.

Inspirations and Mentors

Are other people in your family engineers or work in a technical field?

Interestingly, engineering has always been a strong presence in my family.

I’m fortunate to belong to a family with a significant number of engineers, including several aunts, uncles, and even cousins who have embraced careers in the technical realm. Remarkably, four of my relatives have chosen the path of electrical and electronic engineering, demonstrating a shared passion for technology and innovation.

This familial connection to the world of engineering has undoubtedly played a role in nurturing my own interests and aspirations in the field.

Has there been a particular person who has inspired you?

While my family’s history of engineers has been a significant influence, I can’t overlook the pivotal role played by my high school science and mathematics teachers. They recognized my burgeoning fascination with mathematics and technology from an early age and provided guidance that set me on the path to engineering. Their mentorship and encouragement were instrumental in nurturing my interest and shaping my aspirations on the field of engineering.

Studying engineering and specialising in instrumentation

Why did you decide to study electrical and electronics engineering?

I chose to study electrical and electronics engineering because of the fascinating perspective it offered. This field allowed me to view the world through the lens of electrical currents and technology. I was captivated by the idea that nearly every aspect of human activity could be translated into terms of electrical principles. Thus enabling us to seamlessly interact with machines and design devices that enhance our daily lives.

The equipment used in production line engineering as an instrumentation engineer

You have experience on a lot of equipment and devices. In your career what types have you installed and maintained?

I’ve had the opportunity of working with a diverse range of measuring instruments that are integral to the manufacturing industries.

My expertise covers a spectrum of devices, including:

temperature transmitters,

flow meters,

level transmitters,

and pressure transmitters.

I’ve also delved into devices designed for liquid analysis, enabling precise control over crucial processes.

Furthermore, I’ve gained hands-on experience with pneumatic and motor-operated valves, which are vital components in industrial automation.

This breadth of exposure has equipped me with a profound understanding of these instruments, empowering me to proficiently install, maintain, and optimize their performance across a variety of industrial contexts.

As an instrumentation engineer what is the most interesting piece of engineering/production line equipment or device you have ever worked on?

The most intriguing piece of equipment I’ve had the privilege to work on is undoubtedly flow meters. What makes them particularly captivating is the intricate nature of their operation and the meticulous care required throughout their lifecycle. From the initial selection and sizing process to ensuring the right measuring technology, sensor, and transmitter are aligned with the specific application, every step demands careful consideration. Deviating from this thorough approach can lead to significant challenges such as measurement errors, inaccuracies, or even instrument damage. The complexity and importance of flow meters in maintaining precision and efficiency within industrial processes underscore their fascinating and critical role in the field of industrial automation and instrumentation.

Working for Guinness as an engineer on production lines

What did your work involve at Guinness?

I started my career as an electrical maintenance technician at Guinness. Whilst at Guinness I was responsible for monitoring the Supervisory Control and Data Acquisition (SCADA) to keep down time generated by electrical devices to the barest minimum. I was also responsible for the maintenance and calibration of measuring instruments, sensors, and valves.

Can you describe a typical week at the brewery within production line engineering?

A standard week within the brewery environment follows a structured routine. The week kicks off with a series of meetings aimed at ensuring that our Key Performance Indicators (KPIs) are on track and aligned with production goals. These discussions set the tone for the week ahead and enable us to focus our efforts accordingly.

One of the fundamental tasks involves distributing maintenance work orders across different departments. These work orders outline the specific preventive maintenance actions that we need to execute on various critical machines within the brewery. This proactive approach is essential in upholding the optimal functioning and longevity of our equipment.

In parallel, a significant portion of our time is dedicated to closely monitoring the production system via the SCADA system. This real-time monitoring enables us to promptly respond to any errors or malfunctions that might arise within the machinery. This vigilant oversight ensures that the production process remains as seamless and efficient as possible.

Collectively, these activities – from strategic meetings to preventive maintenance actions and real-time monitoring – harmonize to uphold the brewery’s operational excellence and contribute to the consistent production of high-quality products.

PPE within the brewing industry

As you were working with beverage manufacturing, what sort of PPE did you need to wear?

For beverage manufacturing, reflective jackets are a staple requirement. This is primarily due to the presence of forklifts and other moving machinery within the facility. These jackets enhance visibility, minimizing the risk of accidents and collisions.

Safety goggles are also an essential component of the PPE ensemble. These goggles shield the eyes from potential hazards such as splashes, debris, and chemicals that are common in manufacturing environments.

Ear defenders are required to reduce exposure to the excessive noise levels generated by the machinery and equipment.

Additionally, safety boots play a pivotal role in safeguarding the feet. These boots are specifically designed to provide protection against impact, punctures, and other potential foot hazards.

Hand gloves are another crucial aspect, particularly for tasks involving manual handling. These gloves offer a protective barrier for the hands, shielding against sharp objects, chemicals, and potential abrasions.

Were there particular health and safety rules you need to follow in terms of hygiene (when on site)?

Working within the brewery environment demanded strict adherence to stringent health and safety regulations, particularly in terms of maintaining impeccable hygiene standards.

Hair and beard nets were mandatory attire within the production facilities. These nets were crucial in preventing any hair or beard particles from entering the production process, ensuring the hygiene and integrity of the products.

A fundamental practice was frequent hand washing, especially upon entering critical production areas. This proactive measure effectively minimized the potential transfer of contaminants and maintained a clean and sterile environment essential for beverage production.

To prevent cross-contamination, the removal of loose adornments such as rings and wristwatches was essential. These items, while seemingly innocuous, could inadvertently introduce contaminants into the production process.

Working for Greenpeg Engineering as Instrumentation Service Engineer on production lines

Typical week in current role

Can you give a breakdown of a typical week for you as an instrumentation engineer?

A standard week in my current company follows a structured rhythm that encompasses various aspects crucial to our operations.

The week kicks off with meetings that set the tone for the days ahead. Much like in most organizations, our Key Performance Indicators (KPIs) are tracked and meticulously analysed to ensure our activities are closely aligned with the overarching company goals. These sessions also provide a platform to discuss upcoming customer visits, project requirements, and the coordination of schedules.

Once schedules are confirmed, the rest of the week is dedicated to implementation. This involves customer visits, a pivotal aspect of our role where we engage directly with clients to understand their needs, offer insights, and provide solutions tailored to their requirements.

Alongside customer interactions, we are actively engaged in supervising ongoing projects, ensuring they adhere to timelines and standards. This involves orchestrating teams, managing resources, and ensuring the smooth execution of project milestones.

Amidst these field activities, there’s also a portion of desk work that demands attention. This desk-based work encompasses tasks such as preparing quotations for potential projects, crafting detailed technical proposals, and engaging in research and analysis to select and size appropriate instruments for ongoing and upcoming projects. This phase allows for meticulous planning and strategizing to ensure that the solutions offered are optimal and aligned with customer needs.

Collectively, these activities – from strategic meetings to customer engagement, project supervision, and desk-based tasks – create a dynamic and multifaceted week. This approach ensures a well-rounded engagement with various aspects of our responsibilities, contributing to our ability to provide effective solutions and exceptional service to our clients.

The role of an Instrumentation Service Engineer

Can you describe what you do technically?

From a technical standpoint, my role revolves around providing comprehensive support for instrumentation projects within the company.

Here’s a breakdown of the technical aspects of my responsibilities.

Customer Visits and Needs Assessment

I initiate projects by engaging in customer visits to gain a deep understanding of their unique requirements. This involves listening attentively to their specifications and goals, allowing me to tailor solutions that precisely meet their needs.

Instrumentation Selection and Sizing

Building on the information gathered during customer visits, I delve into the technical aspect of the projects. This includes meticulously selecting and sizing the appropriate instruments that align with both the customer’s specifications and global industry standards. This step is crucial in ensuring optimal performance and accuracy.

Technical Proposals and Cost Estimation

Once the instruments are identified, I prepare comprehensive technical proposals. These documents outline the proposed solutions, detailing how the selected instruments address the customer’s requirements. Additionally, I provide accurate cost estimates, offering transparency and clarity regarding project expenses.

Project Implementation Supervision

Throughout the project’s execution, I play a pivotal role in supervising the implementation process. This entails closely monitoring the progress, ensuring that milestones are met, and guaranteeing that the project adheres to the established timelines and quality standards.

After-Sales Support Services

My engagement doesn’t conclude with project implementation. I extend after-sales support services to clients, which involves troubleshooting any issues that may arise with the installed instruments. In cases where maintenance is necessary, I ensure prompt and efficient resolution to minimize downtime and maintain operational efficiency.

Conclusion

Collectively, my technical role encompasses the entire lifecycle of instrumentation projects – from initial customer interaction and needs assessment to technical proposal preparation, project supervision, and post-implementation support. This comprehensive approach ensures that our clients receive tailored solutions that meet their exact needs while upholding the highest technical and quality standards.

Time on site as an engineer working on production lines

How much of your time is spent on site with the equipment? How much time is spent doing other things like admin and training?

A significant portion of my time is dedicated to on-site activities, directly engaging with equipment and projects. This encompasses customer interactions, project implementation, and supervising ongoing work to ensure seamless execution. This hands-on involvement allows me to ensure the quality and effectiveness of our solutions.

While the field work forms a substantial part of my responsibilities, I also allocate time for essential administrative tasks. This includes tasks such as documentation, project coordination, and keeping accurate records. These administrative efforts contribute to the efficient management of projects and the smooth operation of our initiatives.

Moreover, I recognize the importance of continuous learning and personal development. To this end, I carve out time for training opportunities that allow me to stay updated with industry advancements and refine my skills. This commitment to ongoing learning enhances my ability to provide cutting-edge solutions to our clients and stay aligned with industry best practices.

In summary, while a significant portion of my time is dedicated to on-site activities, I maintain a balanced approach by also engaging in administrative tasks and investing in continuous learning to ensure I remain well rounded and effective in my role.

Types of equipment used in instrumentation for production line engineering

What are the types of equipment you work with in your current job?

In my current role, I have the privilege of working with a diverse array of equipment, particularly focusing on measuring instruments within the context of broader project involvement. This role allows me to engage with these instruments on a larger scale, as I’m actively involved in project discussions all the way through to execution and successful completion.

Here’s an overview of the types of equipment I work with.

Measuring Instruments

As in my previous role, measuring instruments remain a core focus. These include temperature transmitters, flow meters, level transmitters, and pressure transmitters. However, in my current capacity, I engage with these instruments on a more comprehensive level, addressing both technical specifications and project requirements.

Process Control Equipment

I’m also involved in working with various process control equipment. This includes controllers, actuators, and other devices that contribute to precise control and optimization of industrial processes.

Automation Systems

Automation systems, including PLCs (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition) systems, are integral to my role. I leverage these systems to streamline operations and ensure efficient process management.

Valves and Actuators

Valves and actuators continue to be important components of my work. These devices play a vital role in regulating fluid flow and maintaining precise control within different processes.

Data Loggers and Analyzers

I also interact with data loggers and analyzers, which facilitate data collection and analysis. These tools contribute to data-driven decision-making and process optimization.

Project Management Tools

Alongside the equipment itself, I utilize project management tools and software to effectively plan, coordinate, and oversee project activities. This ensures timely project execution and successful outcomes.

Partnerships with OEMs

One unique aspect of my current role is the opportunity to collaborate with Original Equipment Manufacturers (OEMs) from around the world. These partnerships empower me to confidently offer solutions tailored to instrumentation needs in various process industries.

By engaging with this diverse range of equipment and taking a holistic approach to projects, I’m able to provide comprehensive solutions that align with industry standards, customer specifications, and global best practices.

Most challenging part of the job

What do you find most challenging when you are working – technical side, people/customers or logistics (travel etc.)?

Undoubtedly, the most challenging aspect of my work revolves around interactions with people, particularly customers.

When customers are not able to clearly articulate their project requirements, it presents a significant hurdle. This lack of clarity makes it challenging to recommend and provide solutions that precisely align with their specific needs. Ensuring that the proposed solutions are accurate and applicable becomes a complex task when the project requirements are not well-defined. Addressing this challenge requires effective communication and a thorough understanding of the customer’s objectives to arrive at tailored and effective solutions.

Example of a challenging task in instrumentation engineering

What has been your most challenging task so far?

One of the most challenging tasks I’ve encountered thus far was during the early stages of my career. The task involved traveling to the eastern part of the country to deliver a project for a customer. However, upon arriving at the site, I realized that the customer had a list of specific expectations for the instrument that they hadn’t communicated during our initial project discussions.

This unexpected turn of events posed a significant challenge. The instrument we had initially selected and planned for was not equipped to fulfill the additional tasks the customer now required. This misalignment between the customer’s expectations and the capabilities of the chosen instrument led to a complex situation that required immediate resolution.

In collaboration with the instrument’s manufacturer, we worked tirelessly to find viable solutions that could meet the customer’s additional requirements.

While we were able to address most of the customer’s needs through this collaborative effort, the situation served as a valuable lesson. It underscored the critical importance of comprehensive project discussions at the outset to ensure that all expectations are thoroughly understood and addressed from the beginning.

This experience reinforced the significance of effective communication and meticulous planning in avoiding potential challenges down the line.

Quick fix situations in production line engineering

Have you ever arrived on site and found that it was much easier than you expected? For example, did you ever need to simply switch on a machine.

The scenario you’ve described is more common than one might think, particularly for straightforward malfunctions.

There have been instances where arriving on-site revealed that the solution was simpler than anticipated – often as simple as restarting the machine. This quick fix often resolves the immediate issue and restores the system’s functionality.

However, it’s important to recognize that while restarting might address the symptom, it doesn’t necessarily provide insights into the root cause of the error. In the pursuit of effective troubleshooting, it’s crucial to delve deeper and understand the underlying factors that led to the malfunction in the first place. This proactive approach not only prevents the issue from reoccurring but also contributes to a better grasp of the system’s behaviour and potential areas of improvement.

So, while it’s certainly a relief to find that some issues are easily resolved, the bigger picture of understanding and addressing the root causes remains a pivotal part of ensuring long-term system reliability and optimal performance.

Course Instructor

You have also worked as a course instructor. How did you explain things so that they were easy to understand?

As a course instructor, I found that breaking down complex concepts into relatable scenarios was a highly effective approach to ensuring easy understanding for trainees. I approached it using visual aids, real world applications, interactive learning, and encouraging questions.

What did you personally learn from your time as a course instructor?

My experience as a course instructor has been an ongoing journey of personal growth and learning. It has enhanced my communication skills, adaptability, confidence, patience, and empathy. I also learn from trainees as they often bring diverse experiences and insights to the classroom.

Future instrumentation engineers

Why would you recommend this type of field service engineer role to someone who has studied electrical and electronics engineering?

I wholeheartedly recommend a career in field service to anyone interested in knowledge enrichment, dynamic challenges, hands-on technical experience, personal growth, travel, and adventures. The role of a field service engineer role in industrial automation is not only intellectually stimulating but also offers the chance to explore different places, work with a variety of technologies, and make a meaningful impact.

Apart from a strong technical background, what are the three most important skills to have?

Beyond a robust technical foundation, possessing excellent communication skills, time management and strong problem-solving skills enable you to effectively bridge the gap between intricate technical concepts and practical solutions. This ensures smooth operations and positive outcomes for both the client and the team.

What sort of personality traits are ideal for a service engineer?

The key traits for a service engineer are empathy and patience, adaptability, attention to detail, resilience, and commitment to continuous learning.

The author

Francis Onukwufor has a degree in electrical and electronics engineering as well as a lot of engineering experience particularly in instrumentation. He has worked for Guinness Nigeria and now works for Greenpeg Engineering. Francis is based in Nigeria.

Very valuable information, thanks for this effort.