Spotlight on a Biomedical Engineer being an Innovator

This article focuses on the life of a Biomedical Engineer in Zambia. George Nyirenda has studied biomedical engineering and is now studying industrial engineering. He works as a Biomedical Equipment Technologist for the Ministry of Health of Zambia. He is also an innovator and has produced a device to combat cholera by making clean drinking water from air. The device is called Mwetosh Water.

Life of a Biomedical Engineer and Inventor in Zambia

Background

Could you give a brief description of your background and what led you to biomedical and industrial engineering? Were there any childhood interests which were a factor?

My journey into biomedical engineering stems from a confluence of factors, including both personal interests and practical considerations. Growing up, I’ve always had a curiosity about how things work, coupled with a passion for applying technology to solve real-world problems. While contemplating my academic path, I found myself torn between pursuing a career in medicine or delving into the realm of Information Technology (I.T.).

However, it was a pivotal conversation with a friend that introduced me to the field of biomedical engineering. Intrigued by the prospect of merging my interests in technology and healthcare, I embarked on extensive research to understand the breadth and depth of this interdisciplinary field. What I discovered captivated me – the opportunity to design innovative medical devices, improve healthcare systems, and contribute to advancements in both medicine and technology.

Reflecting on my childhood interests, I realise there were subtle signs pointing me towards this direction. Whether it was disassembling gadgets to understand their inner workings or harbouring a fascination for biology and human anatomy, I now see how these early curiosities laid the foundation for my eventual pursuit of biomedical and industrial engineering.

In essence, my decision to pursue biomedical and industrial engineering was not just a matter of happenstance but a deliberate choice driven by a convergence of passion, curiosity, and the desire to make a meaningful impact in the intersection of healthcare and technology.

Understanding how things work

Have you always liked knowing how things work?

Absolutely, from a young age, I’ve had a natural curiosity about how things operate. Whether it was tinkering with gadgets, troubleshooting technology issues for family and friends, or delving into the mechanics of everyday objects, I’ve always found joy in unravelling the mysteries of functionality.

Inspiration

Has there been a particular person who has inspired you?

Yes, indeed. Being the go-to ‘tech guy’ for my family, I’ve developed a knack for problem-solving and fixing things. Whether it’s troubleshooting a malfunctioning device or finding innovative solutions to challenges, I thrive on the satisfaction of resolving issues and restoring functionality.

Could you name two great engineers?

My greatest inspiration undoubtedly stems from my father, who is a mechanical engineer. Witnessing his dedication, expertise, and passion for engineering has been profoundly influential in shaping my own aspirations and work ethic.

Additionally, Professor Clive Chirwa, a globally renowned engineer known for his ground breaking inventions, has been a source of inspiration through his remarkable contributions to the field.

One well-known engineer is Nikola Tesla, whose pioneering work in electrical engineering laid the foundation for numerous modern technologies.

A lesser known but equally remarkable engineer is Eng. Musonda, whom I had the privilege to meet during my internship at Levy Teaching Hospital. His mentorship and guidance have been invaluable in shaping my journey as an engineer.

Studying and working as a Biomedical Engineer

You are completing your degree in Industrial Engineering as well as working as a Biomedical Equipment Technologist. How do you balance working and studying?

Through effective time management, I ensure that I prioritise my responsibilities efficiently. By completing my work tasks diligently during designated hours, I create dedicated time slots for studying and attending classes. This approach allows me to maintain a balanced workload while pursuing my degree in Industrial Engineering and working as a Biomedical Equipment Technologist. Additionally, I carve out specific time for family and friends, committing to quality interactions during evenings and weekends. By adhering to a structured schedule and setting clear boundaries, I strike a harmonious balance between my professional commitments, academic pursuits, and personal life.

Equipment

What are the types of equipment you work on (and have worked on)?

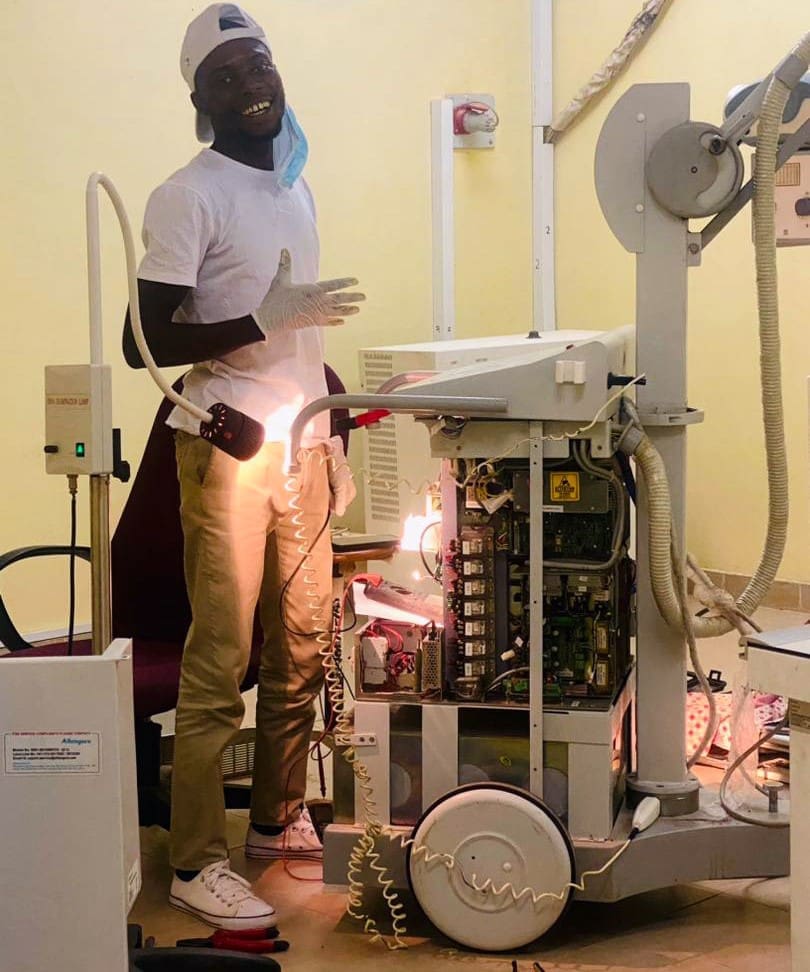

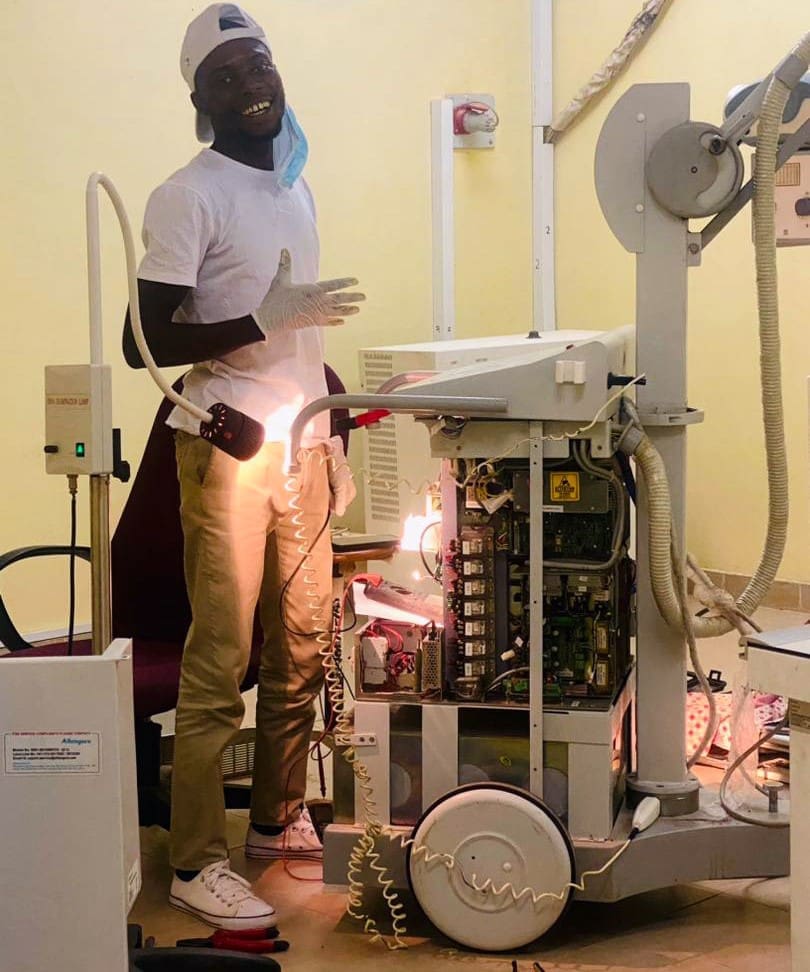

In my role as a Biomedical Equipment Technologist, I have experience working on a diverse range of medical equipment commonly found in hospital settings. This includes but is not limited to patient monitors, infusion pumps, defibrillators, ultrasound machines, anaesthesia machines, surgical instruments, and diagnostic imaging equipment such as X-ray machines, CT scanners, and MRI machines.

What is the most interesting piece of equipment on which you have ever worked?

Among the various pieces of equipment I’ve encountered, the digital X-ray machine stands out as particularly fascinating. Its advanced imaging capabilities, coupled with the intricate technology behind its operation, make it a compelling piece of equipment to work on.

What has been the most difficult piece of equipment you have ever worked on?

Undoubtedly, the CT scan machine presents the most significant technical challenges. Its complex design and sophisticated functionality require a deep understanding of imaging principles, computerised tomography techniques, and intricate calibration procedures, making it one of the most demanding pieces of equipment to troubleshoot and maintain.

Is there a piece of equipment you would you like to work on?

Looking ahead, I am eager to expand my expertise by working on a heart-lung machine. This pivotal device plays a crucial role in cardiac surgery by temporarily taking over the functions of the heart and lungs, facilitating complex procedures. The opportunity to contribute to the maintenance and optimisation of such life-saving equipment would be both professionally rewarding and personally fulfilling.

Inventing a Biomedical Engineering device

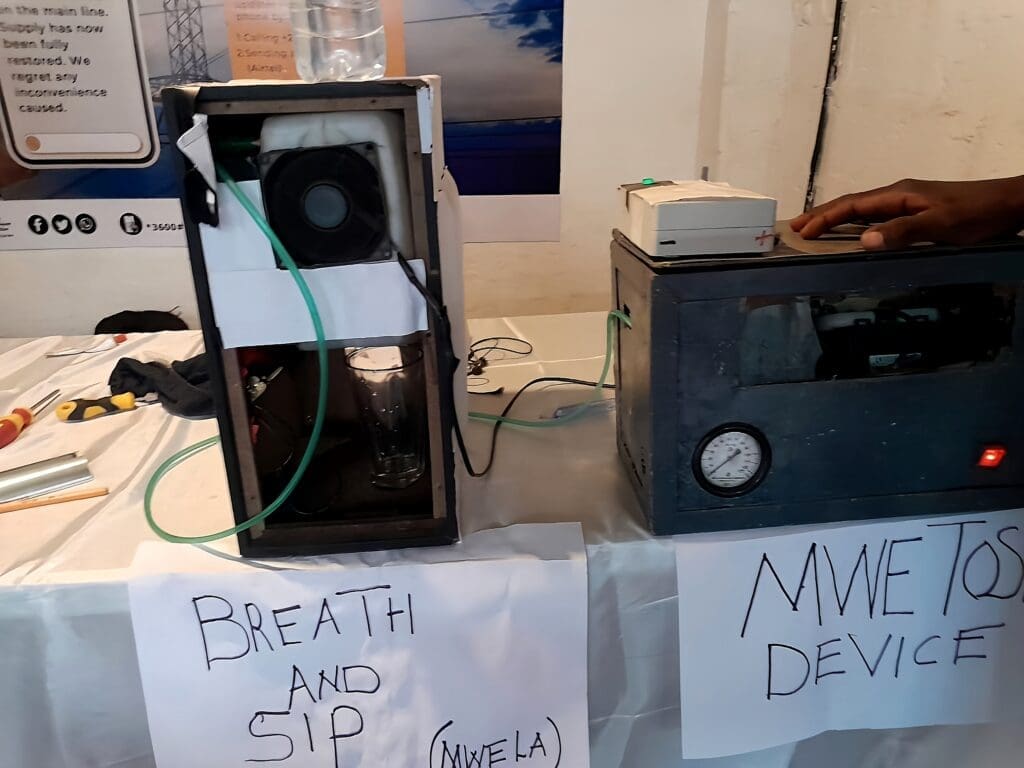

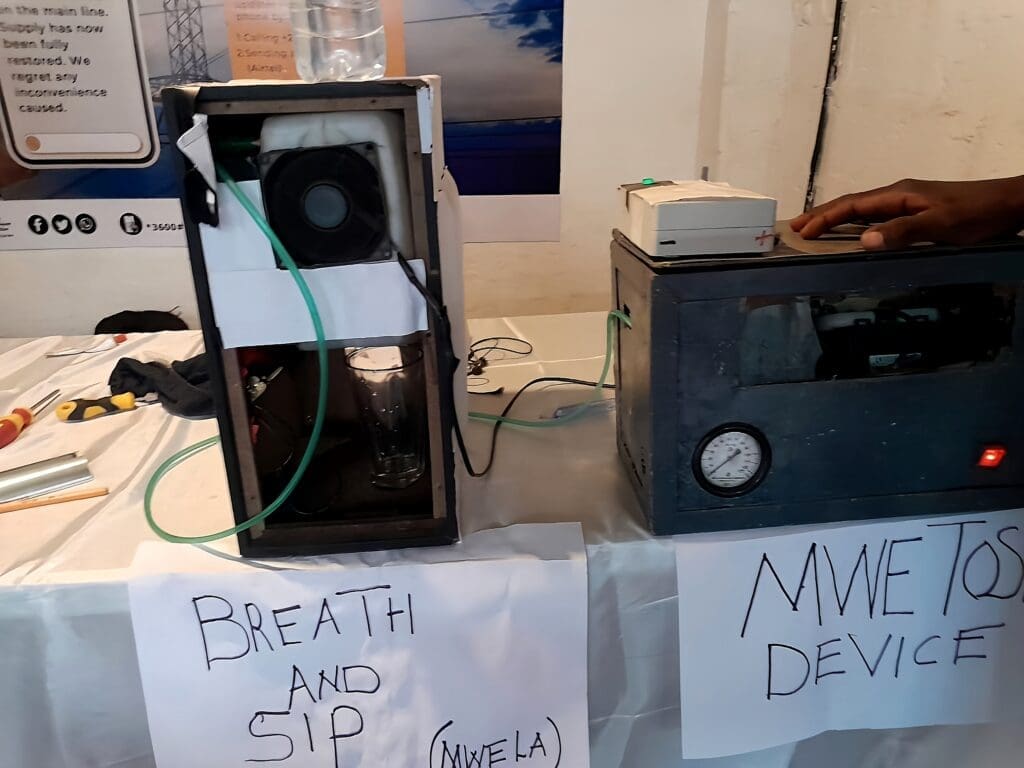

You have invented a device called Mwetosh Water.

How did you have the initial idea for this device?

The initial idea for the Mwetosh Water device stemmed from observing the challenges faced by my community, particularly in rural areas like Luangwa, Zambia. Witnessing firsthand the lack of access to clean drinking water and the resulting prevalence of waterborne diseases due to reliance on shallow wells or direct consumption from contaminated rivers such as the Luangwa and Zambezi, prompted me to innovate a solution.

I sought a way to provide my community with easy and affordable access to clean drinking water, leading me to conceptualise the Mwetosh Water device. The idea emerged from considering how air, a readily available resource, could be harnessed to purify water effectively, thereby addressing the pressing need for safe drinking water in my community.

How long did it take you from your initial idea to producing clean drinking water?

It took me approximately 10 months from the initial idea to producing clean drinking water with the Mwetosh Water device. During the first two months, I focused on designing the concept and gaining a comprehensive understanding of water quality standards for drinking purposes. This involved extensive research, studying air components, calculations, and coding to ensure the effectiveness of the device. Over the remaining months, I dedicated my efforts to organising the components and rigorously testing my theories to ensure they would work in practice. This phase demanded countless hours of work each day, often leading to sleepless nights, as I worked tirelessly to bring the device to fruition and ensure it performed as intended.

Manufacture

How easy is to manufacture?

Manufacturing the Mwetosh Water device was not an easy task. I undertook the manufacturing process in my backyard and a friend’s workshop. However, numerous challenges, such as sourcing materials and access to necessary machinery, presented significant barriers throughout the manufacturing journey. Despite these obstacles, I persisted in overcoming each challenge, leveraging whatever resources were available to me to bring the device to life. While the process was far from straightforward, determination and resourcefulness enabled me to navigate the complexities of manufacturing and ultimately produce the Mwetosh Water device.

Typical week as a Biomedical Engineering Equipment Technologist

What’s your typical week like?

My typical week as a Biomedical Equipment Technologist is dynamic and involves a variety of tasks. Each week typically begins with conducting ward rounds, during which I inspect all the medical equipment in use and engage with users to address any issues they may be experiencing. Following this, I attend morning briefing meetings to stay updated on any new developments or priorities within the healthcare facility.

Throughout the week, I devote time to checking the functionality of all equipment to ensure it is in proper working condition. This includes conducting user training sessions to educate staff on the proper use and maintenance of equipment.

A significant portion of my week is dedicated to planned preventive maintenance activities, during which I perform routine checks and servicing on equipment to prevent potential issues and ensure optimal performance. Additionally, I allocate time for corrective maintenance tasks, addressing any equipment malfunctions or breakdowns promptly to minimise disruptions to healthcare services.

Time breakdown and support

How much of your time is spent ‘hands on’ and how much doing other things?

I spend approximately 30 percent of my time engaged in hands on activities. This primarily involves conducting planned preventive maintenance (PPM) on medical equipment to ensure their optimal functionality and minimise the risk of breakdowns. Additionally, I allocate some time to performing partial corrective maintenance tasks as needed.

The remaining portion of my time is dedicated to various other tasks. A significant portion is devoted to studying and staying updated on the latest advancements in medical technology. Given the constant evolution of technology, it’s crucial for me to remain abreast of new developments to effectively support the equipment within the healthcare facility.

Furthermore, I spend time interacting with users, addressing their queries, providing training on equipment operation and maintenance, and offering technical support as required. This aspect of my role is essential for fostering a collaborative environment and ensuring that staff members feel confident in utilising the equipment to deliver quality healthcare services.

Who gives you support when you need it?

When seeking support, I rely primarily on the management within my organisation. They play a pivotal role in facilitating my needs within the work environment, whether it pertains to necessary resources, guidance, or professional development opportunities. Furthermore, my supervisor, Mr. Sinkala, who oversees technical and consultation support at the provincial level, serves as a valuable source of assistance and mentorship. Their combined support ensures that I am equipped with the necessary tools and guidance to excel in my role and contribute effectively to the organisation’s objectives.

Most challenging part of the job as a Biomedical Engineer

What do you find most challenging when you are working – technical side or people?

For me, the most challenging aspect when working often revolves around the technical side of tasks rather than dealing with people. I find that navigating complex technical problems, troubleshooting issues, and ensuring the successful implementation of solutions can be particularly demanding. While interactions with colleagues and stakeholders are important and sometimes present their own challenges, I generally feel more comfortable in those situations compared to grappling with intricate technical details and finding effective solutions.

Travel as a challenge of the job

How much travel do you do, and how does this add to the challenges of your job?

As an innovator and researcher, I find myself traveling extensively due to invitations to exhibitions, conferences, and symposiums where I showcase my innovations, such as the Mwetosh air device.

However, managing frequent travel alongside my responsibilities at the hospital poses certain challenges. Firstly, scheduling becomes a juggling act, as I must balance my commitments at work with the demands of attending events and conferences. This requires meticulous planning and coordination to ensure that patient care is not compromised.

Additionally, the logistics of travel can be taxing, involving long hours of transit, unfamiliar environments, and potential disruptions to routine. Maintaining productivity and focus amidst these challenges can be demanding, especially when adapting to different time zones and climates.

Furthermore, the absence from the hospital during periods of travel can create gaps in continuity of care and coordination with colleagues. Clear communication and delegation of tasks are essential to mitigate any potential impact on patient outcomes and workflow efficiency.

Despite these challenges, the benefits of travel far outweigh the difficulties. Each journey presents opportunities for networking, collaboration, and professional development, ultimately enriching my work and driving innovation in healthcare. By embracing the challenges of travel and leveraging these experiences to enhance my skills and expertise, I am better equipped to contribute meaningfully to both my research endeavours and patient care responsibilities.

Example of easy task

Have you ever arrived on site and found that it’s been much easier than you expected? For example, have you just needed to switch on a machine.

Yes, there have been numerous occasions where I’ve arrived on-site, sometimes even on my days off, in response to an emergency call about malfunctioning equipment, only to find that the issue was much simpler than anticipated. In many cases, it boiled down to a missed step, such as neglecting to press a crucial button or overlooking a basic setting when turning on a machine.

Making a future star of a Biomedical Engineer

What sort of personality traits do you need to work as a medical/biomedical field service engineer?

Firstly, a strong foundation in engineering principles is paramount. A deep understanding of mechanical, electrical, and software systems is crucial for effectively troubleshooting and maintaining complex medical equipment.

Communication skills are equally vital. Clear and concise communication is essential for conveying technical information, providing instructions, and addressing concerns. Moreover, the ability to communicate empathetically and effectively listen to the needs of users fosters trust and collaboration, ultimately enhancing customer satisfaction.

In addition to technical expertise and communication skills, strong management abilities are indispensable. Field service engineers often juggle multiple tasks simultaneously, from responding to urgent service calls to managing scheduled maintenance activities. Effective time management, prioritisation, and organisational skills are essential for balancing competing demands and ensuring timely resolution of issues.

Furthermore, a proactive approach to problem-solving is characteristic of successful field service engineers. The ability to think critically, analyse situations, and devise innovative solutions is invaluable when encountering unexpected challenges in the field. Adaptability and flexibility are also essential traits, as the nature of the job often requires responding to unpredictable situations and adjusting plans accordingly.

Finally, a commitment to continuous learning and professional development is essential in the rapidly evolving field of medical technology. Keeping abreast of advancements in equipment technology, industry regulations, and best practices ensures that field service engineers can deliver the highest quality of service and support to their clients.

Apart from a strong technical background, what are the three most important skills to have?

Apart from a strong technical background, three additional crucial skills for success as a medical/biomedical field service engineer are:

Communication Skills

Problem-Solving Aptitude

Time Management and Prioritisation

Reasons to become a Biomedical Engineer

Why would you recommend this career to someone who is studying now?

First and foremost, this career offers a unique opportunity to make a meaningful impact on healthcare delivery and patient outcomes. As a field service engineer, you play a crucial role in ensuring the reliable operation and maintenance of medical equipment, ranging from diagnostic imaging devices to life-support systems. By effectively servicing and repairing this equipment, you directly contribute to the quality of patient care and safety in healthcare facilities. For individuals passionate about using their technical skills to make a difference in people’s lives, this career path offers a fulfilling and rewarding opportunity to do so.

Additionally, working as a medical/biomedical field service engineer provides a perfect blend of medicine and engineering, making it an exciting and intellectually stimulating profession. This unique combination allows individuals to apply their engineering knowledge and skills to address real-world healthcare challenges and innovations. It offers the chance to work at the intersection of two dynamic fields, constantly learning and adapting to advancements in both technology and medicine. For individuals who have an interest in both engineering and healthcare, this career path provides an ideal avenue to pursue their passion and expertise in both areas.

Furthermore, a career as a field service engineer offers excellent prospects for professional growth and development. With the rapid evolution of medical technology and increasing demand for healthcare services worldwide, there is a growing need for skilled professionals who can install, maintain, and repair medical equipment. As such, individuals entering this field can expect ample opportunities for career advancement, specialised training, and professional certifications. Whether working for medical equipment manufacturers, healthcare institutions, or third-party service providers, field service engineers can carve out diverse and fulfilling career paths tailored to their interests and goals.

About the author George Nyirenda

Background

I am George Nyirenda, currently serving as the Medical Equipment Coordinator for Luangwa District. Alongside my role, I hold key positions in professional organisations, serving as the Vice Chairman of the Engineering Institution of Zambia’s Biomedical Engineering Section and the Publicity Secretary for the Biomedical Engineering Association of Zambia.

With a background as a Medical Equipment Technologist with the Ministry of Health, I have earned recognition as an award-winning innovator. My passion for biomedical engineering and research has driven me to develop numerous innovations, including the Mwetosh Air Device, which represents my latest achievement.

My journey into innovation began under the guidance of Mr. Innocent Bwalya, my former lecturer who recognised my potential and nurtured my skills in innovation and programming. As the Biomedical Engineering Students President, I led with a focus on fostering creative thinking and problem-solving.

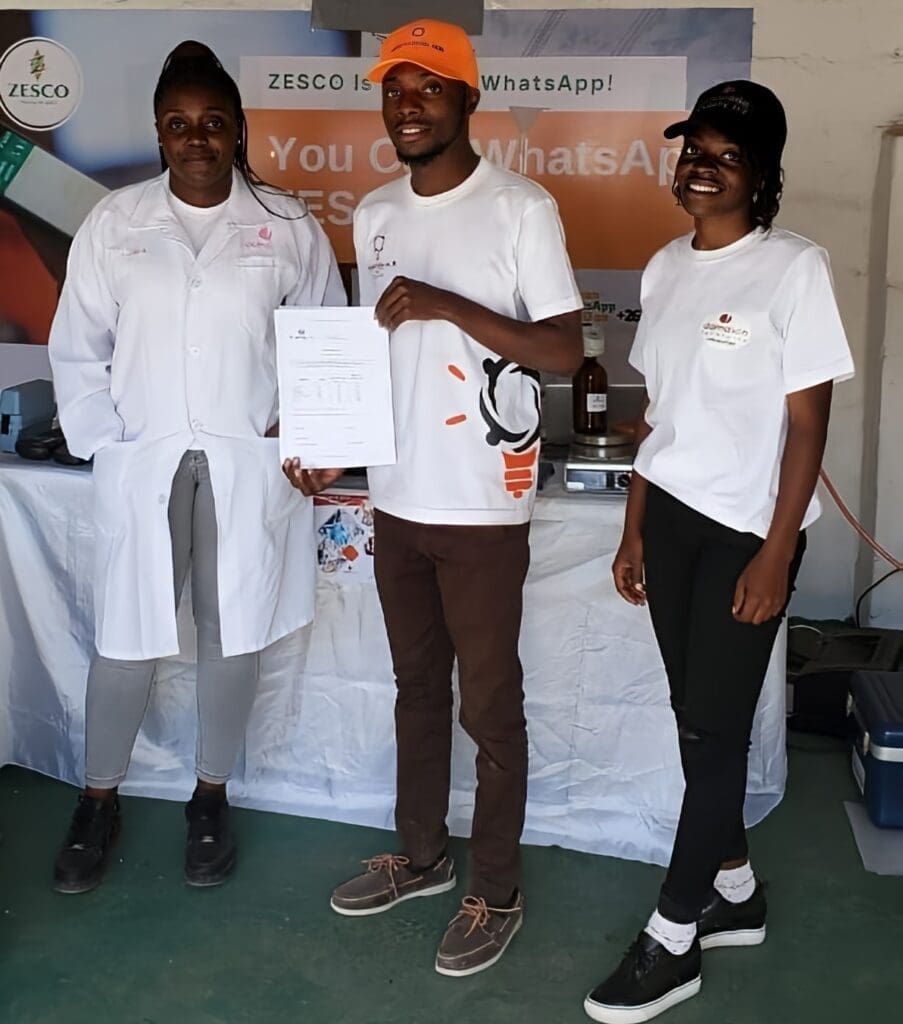

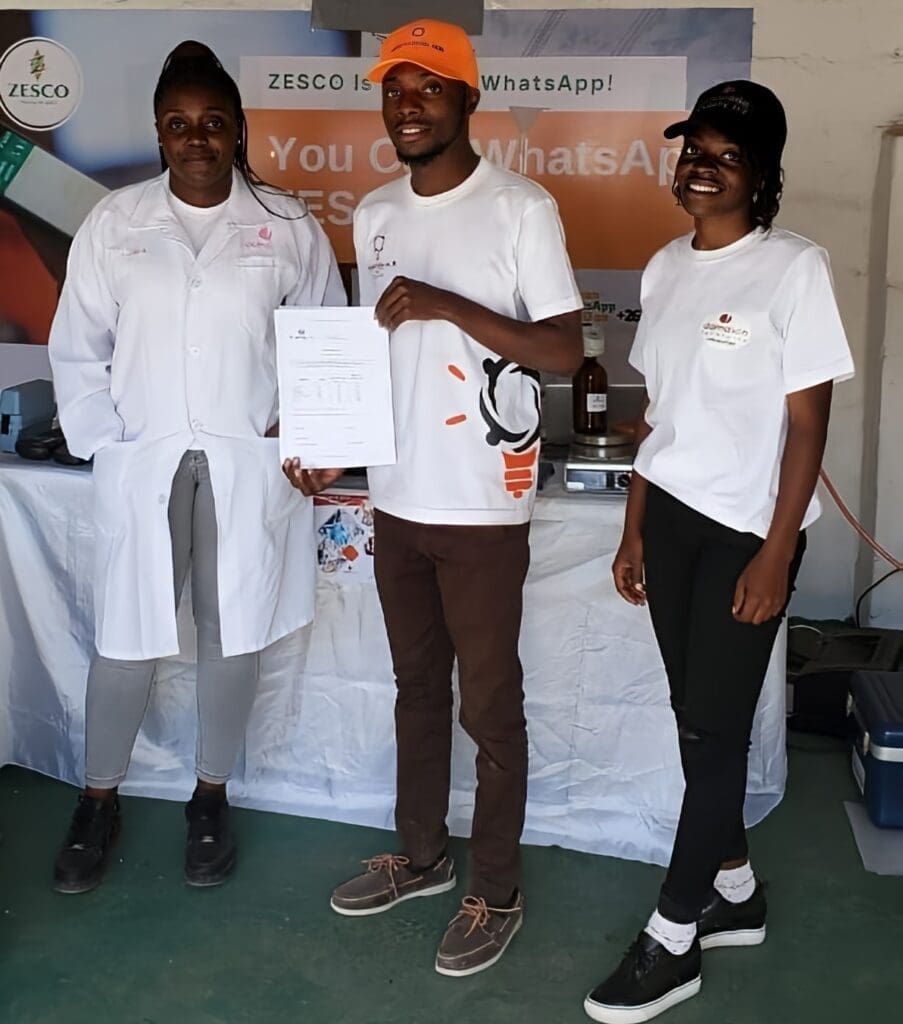

One of my early innovations, the Neonatal Baby Monitoring System, garnered media attention and earned me opportunities to showcase my work at prestigious events like the Zambia International Trade Fair. In collaboration with my partner Dimas Mulenga and my team, I received accolades including the Runners Up Award and a Gold Medal for our contributions to the field of biomedical engineering.

Throughout my career, I have benefited from invaluable mentorship, particularly from individuals like Mr. Musonda, Mr. Mpande, and Mr. Chola during my internship at Levy. Their guidance equipped me with practical skills and knowledge, paving the way for my professional journey which began in December 2020 through my first appointment.

Research and innovation

In 2021, I embarked on my first research project, resulting in the development of the Geomost Oxygen System—a portable oxygen plant that refills oxygen cylinders in record time. While my innovation earned nominations and recognition, it’s the unwavering support from mentors like Mr. Mpande that I value, and he has always been one of the first people I consult to on my research and innovation.

Supported by the management at Luangwa District Hospital, including Dr. Chola and Dr. Mundia and Mr Zulu, I continue to push the boundaries of innovation in healthcare. My recent accomplishment includes conducting a case study titled “Enhancing Neonatal Respiratory Support: Evaluating the Efficacy, Safety, and Parameter Usage of Bubble CPAP in Luangwa District Hospital, Zambia” in 2024, followed by the development of the Mwetosh Air Device in 2024.

Further reading

Spotlight on life of a Biomedical Engineer in the UK

A Biomedical Engineering PhD Student – life and opportunities

Life in Biomed working for the best for new-borns

Responses