Life of a Field Service Engineer who loves Italian technology

Al Bates has extensive experience with automation equipment. He works for an Italian packaging company, SIPA as a field service engineer and is currently onsite in Jamaica installing a new bottle production line for Coca Cola.

Field Service Engineer working on packaging machines for Italian company SIPA

Background

Were you always interested in how things worked?

I have been interested in how things work since I was in Middle School. My dad worked on cars back then, so I was around the mindset of:

“I can fix this myself.”

Were there any childhood interests which were a factor?

I was into bicycles and assembled my second bicycle with my own two hands after months of saving money for it. Still to this day I prefer to fix things myself if I have the time available.

Have you always liked fixing things? Do you fix things even when you are not at work – around the home?

When I am at home, I enjoy changing out light switches, fixtures etc. to more modern tech/smart fixtures. I have even re-piped my irrigation system to where winterizing the system is a piece of cake.

Mentors and inspirations

Who have been your mentors and inspirations at different stages of your life?

Early in my career I was fortunate to have positive individuals to give me input. These individuals told me that I could do better than my father before me.

Mike McCarthy of Redwood Technology Ventures is the first individual that comes to mind. I was ten years his senior when he was my supervisor. What he did was to encourage me and point me in the right direction when I needed it.

Eddie Hutwagner of Georgia-Pacific LLC was the other individual that helped me early on in my career. He was the Operations Manager at a pillow manufacturing plant where I was the Lead Inhouse Mechanic. Eddie poured a wealth of knowledge into me for a good 4-5 years. As well, we shared hobbies and many personal life struggles together.

Field Engineer in Industrial Automation

You are an experienced Field Engineer in different types of industrial automation.

How important is software knowledge in your roles?

I do not deal with software too much. The European machine manufacturers take a lot of pride in their programming. So, they limit what and how much an individual can change and or adjust in the actual program. I appreciate their thoroughness when it comes to programming.

How quickly can you learn a new piece of equipment?

I feel that I am a quick learner when it comes to things but learning new equipment takes time, even years to be truly knowledgeable. Earlier in my career, I was in the meat forming industry for about five years and knew the machines and the process very well. I have been in the blow moulding industry for just under a year now and feel that I still have a long way to go before I can think of myself as a professional in the field.

Why would you suggest this type of field engineering to someone at the beginning of their career?

I would highly recommend this type of field engineering to all new engineers beginning their careers. That’s because I enjoy the challenge of installing new equipment, troubleshooting down equipment, implementing new machine upgrades etc. Also, I enjoy traveling and meeting new people.

Equipment

You have experience of a range of equipment and handling the installation, service, and training.

What are the different types of equipment you have worked on during your career?

I have worked on so many kinds of equipment over the years.

Patty Formers

Danish rendering machines

German meat slicers

Italian packaging machines

American Packaging machines

Now:

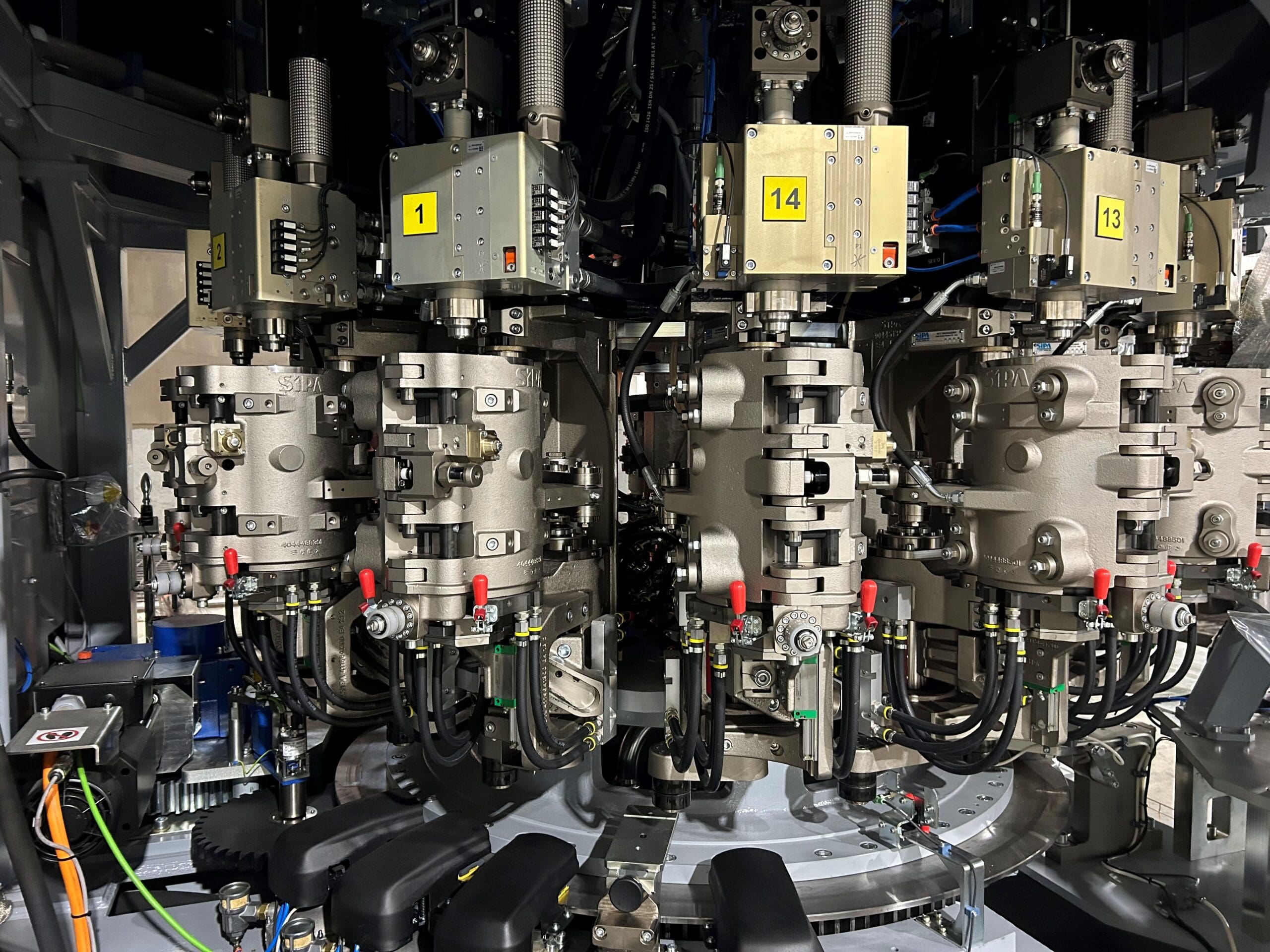

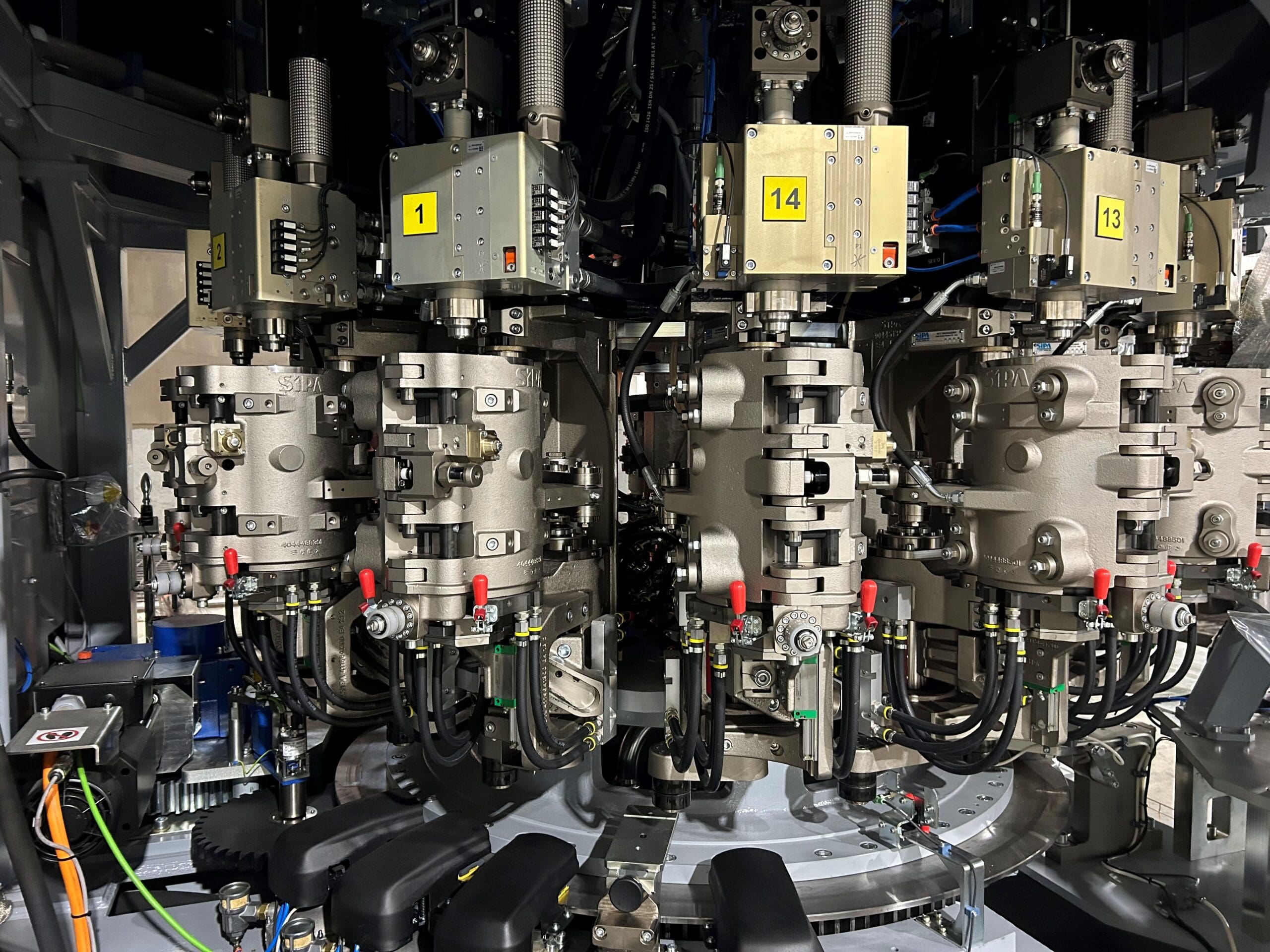

Italian blow moulders

and slowly getting exposed to Fillers.

What is the best/most interesting piece of equipment you have ever worked on?

I would say that the most interesting piece of equipment that I have worked on to date would be the Italian packaging machines, but I worked on them for years and knew them very well. I believe that the Italian blow moulders will be my favourite machine in time.

Working for an Italian packaging company as a field service engineer

What have you learnt from working as a field service engineer for an Italian packaging company?

I completely love working for an Italian company. Family matters and they know this.

They hire individuals for their skills and talents, not for how many hours they are willing to work.

Training is in Italy, and who would not want to visit Italy?

For the most part they try hard to have the technicians and engineers at home at the weekends and even try to allow for one week a month for family or personal time.

They work you when work is needed not just to work you. I worked for another company that would send individuals out at the company’s expense just to have someone on site and not sitting at home. I was at 90%+ travel doing nothing productive on site and being away from my family. This was a no-win situation for both parties that came to an end with the company in financial distress.

Why would you recommend working for an Italian company?

I would recommend working for an Italian company for numerous reasons.

The main one is the quality of the equipment, which is top notch. Others may say that Italian equipment costs less than say German and American equipment because of poor quality. I would say that the other manufacturers push harder at sales than the Italians do and quality has absolutely nothing to do with it. To be honest I cannot help but think of the Etruscan civilization (Italians), who were the true builders of ancient Rome.

Typical week as a Field Service Engineer for Italian company SIPA

What’s your typical week like?

My typical week while out at a job will mean that I will work roughly ten hours a day on site. More times than not, I have been teamed up with one or more individuals to handle the job scope on hand. I have been on emergency repairs where I was all by myself many times over my career but only a handful of times for my current employer.

My typical work week if I am at home is very different. I work on reports and expenses. I take a lot of Cyber Security Awareness Testing. The rest of the time I simply have my phone on me in case an unscheduled job arises.

How much of your time is spent ‘hands on’ in the field and how much is doing other things?

I believe that I am physically in the field about 60%-70% of the time. Of the remaining time 40%-50% of my time is spent on clerical work until completed, then home/family time.

Support

Which other people in your company give you support?

I have numerous individuals that I can reach out to if I need support myself. Stuart Wilson (Senior Lead Engineer) has been extremely helpful as has Dumitru Mihalcea (Technical Operations Manager).

What are your tips for the best ways to share knowledge and experience with other engineers?

I would have to say that the best way that I have been able to share my years of knowledge is face to face with my customers. Usually, I am walking around and observing technicians working looking for opportunities to help them with a little friendly direction. Direct messaging and emails are other ways of helping each other.

On one occasion, I was contacted on LinkedIn for technical support. A technician in another country contacted me because he was unable to contact anyone on his normal help line.

Building relationships with customers

How do you start to build a relationship with a new customer?

The key thing is to be authentic and personable with your customers.

How do you approach visiting a new customer for the first time?

When I am assigned a new customer, I do a little research on my end. I will look at the customer’s webpage. It helps to know what the customer is manufacturing. I will look at their history, news, mission, vision, and values. In addition, I will look at my contact person’s LinkedIn profile.

Looking into this information lets you know if you are walking into a well-established company with content employees or a hot box of new personnel trying to reinvent the company. All this information will help you sell the fact that you are there to provide top notch service. Building relationships with customers not only helps you on the job site but establishes a better relationship between the customer and your employer.

Most challenging part of the job as a field service engineer

What do you find most challenging when you are working?

The most challenging part of my job would be the extended times away from my family. I am given a lot of time at home with my family so when the call for my services comes in, I must be ready and willing to go.

Another challenging part of the job is that most of my colleagues are from other parts of the globe and their English is their second language or they do not speak English at all. Google Translator has been a reliable friend to me for many years. We all carry smart phones, and my advice is to be smart and utilise all the features.

The technical side of my job is always more challenging than dealing with customers. I am working on the newest, latest, and greatest technology offered by my employer so many times things are new to me. The process is for the most part always the same but how it is done may be different. I have always got along well with people. You will run into individuals that do not get along with anyone though, that is on them. In that case, do your job to the best of your ability and move on to the next one.

Examples of challenges

What has been your most challenging job to date?

The most challenging job that I have ever done was having to climb into Haarslev Industries Disc Dryers to perform ultrasonic metal thickness tests at different points inside of the machine. This was work in a confined space in an extremely large machine (140 ton+) that rotates during normal operation.

Have you ever arrived on site and found that it’s been much easier than you expected? For example, have you just needed to switch on a machine.

One of the easiest jobs that I have ever been on was down in Saint Lucia. The customer lost communication between HMI (Human Machine Interface) and the machine. So, the customer changed out the HMI and a few other components trying to reestablish communication but was unsuccessful. The customer even hired a third-party electrical contractor to try and solve their communication issue, he was unsuccessful as well.

I reinstalled all the original electrical components and as I was installing the communication cable into the back of the HMI, I noticed that it looked as if it had been repaired. The in-house technician assured me that the cable was good because he had checked the resistance. The customer did not have the correct cable for replacement, so I reformatted the HMI to utilize a different cable in a different port. Full communication was reestablished, and I was offered a very interesting position there in Saint Lucia.

Work life balance as a field service engineer working for an Italian company

How do you personally handle the stress of working as a field engineer?

The life of a field engineer can be stressful at times like any career of course. I focus on my family first. If your family is well, they will support you with your career choice.

What advice would you pass on to others in the field?

Advice to others in this field of work would be to take one day at a time because we are not promised tomorrow, so give your best every time. Do not take short cuts on any job and put the Panduit covers back in place. Always leave the equipment and machines better than you found them.

How do you keep a work life balance?

How do I keep my work life balance? Prayer.

Work life balance is a real thing, and it is possible, and it can be achieved.

Further reading

Al Bates and Carl Tope advise on how to handle on-site communication challenges

Production Line Field Service Engineer and his dog

Food packaging – what is the future?

A food and beverage production line equipment Field Service Engineer – meet Philip Asamoah Boamah

Responses