Focus on life of a food/beverage production line FSE

Philip Asamoah Boamah is an electromechanical engineer who works with equipment for production lines for beverages. He is based in Ghana and currently works for InTech – International Technology of Food and Beverage, s. l. headquartered in Tenerife -Spain. InTech works in partnership with Sidel. Philip has installed equipment in Senegal, Iraq, Congo, Cameroon, and more.

A food and beverage production line equipment Field Service Engineer – meet Philip Asamoah Boamah

Background and path to field engineering

Could you give a brief description of your background and what led you to study electrical and electronic engineering?

I studied Electrical Engineering after school as well as qualifying as a Telecommunication Technician. Then I studied Electrical and Electronic Engineering (Control Systems) at Accra Technical University.

Were you interested in science and engineering when you were a child?

Yes, I was.

I tried to repair home appliances like heaters, blenders, lamp holders, and fan regulators.

Sometimes I used to design and make a car out of a milk can!

That was the beginning and now today I work on advanced machines.

You are the first in your family to become an engineer. Are you now going to encourage other family members to study engineering? And why?

Yes, I am because becoming an engineer will help a lot of people including the people who live where you come from.

Has there been a particular person who has inspired you?

Professor Amevi Acakpovi, Pro Vice-Chancellor of Accra Technical University in Ghana has inspired me.

How did he inspire you?

He showed me how to design a traffic light controller and advised me that I can become who I want to be in future if I put in a little effort.

Transferable skills for production line equipment

You have worked in different roles? What did you learn that you could take with you to your current role?

After my national service, I worked with Twellium Ghana. I started as a Technical Operator, then a shift Technician and after some years, I become Shift Supervisor and Technical coordinator.

As I had experience in beverage production, I could take my skills and work as a Field Service Engineer for InTech.

Cultural differences

You work for a Spanish company which is in partnership with an Italian company. What are the key differences in management styles and ways of doing things?

The management style is similar. The main difference is that my first company was beverage production and the current one installation of beverage machines.

Do you do training courses locally or at Head Office?

Sometimes on site and sometimes at the Head Office for both mechanical and electrical training.

Typical day as a Production Line Equipment FSE

What’s your typical day like?

It depends on the particular piece of work, but mostly we do overhaul and upgrading, maintenance, and install new machines for customers.

How much of your time is spent on site and how much with admin and other tasks?

I am on site all the time. After each piece of work, I write a report and that is what my managers use to see what I am doing.

Which other parts of the organisation give you support?

We are in partnership with Sidel, and so I can ask them for support. It depends on the situation on site but normally, I send an official email to technical support. In the email, I give my name, the machine I am working on, the serial number of the machine and tell them the problem or what help I need from them.

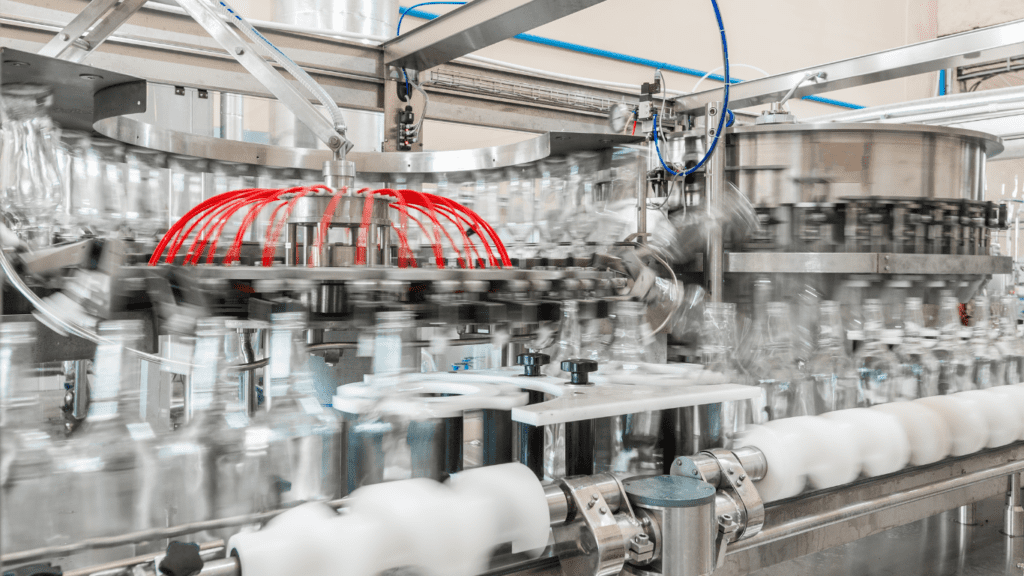

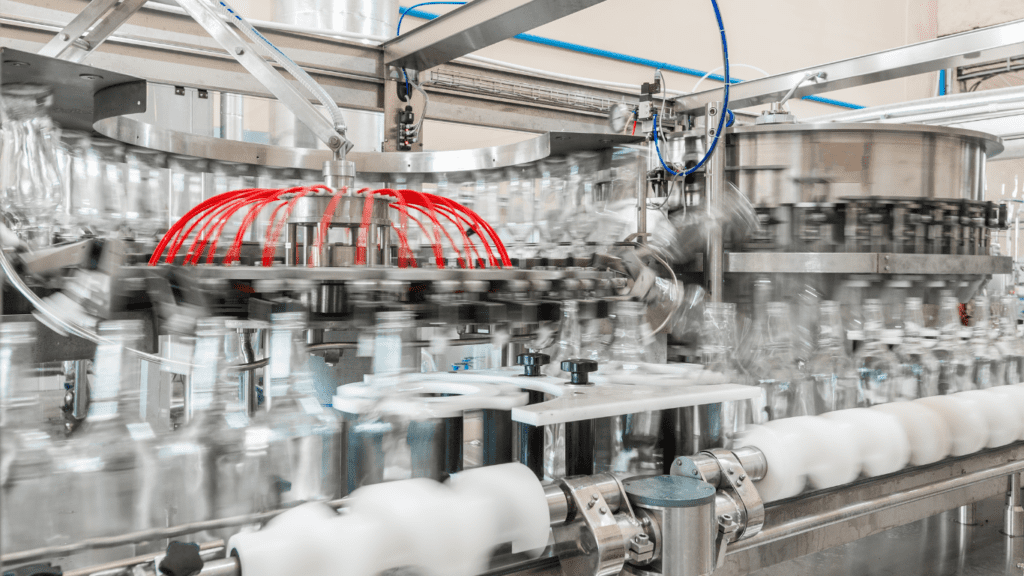

What are the types of equipment you service, maintain, and install?

We have different machines, like:

Blower

Filler

Labeller

Shrink wrapper

Pasteuriser

Pal and depal (palletising and depalletising)

For now, I’m working on the Sidel Fillers – SF 100 FM, SF 300FM, EVOFILL CAN etc.

What is the best piece of equipment you have serviced?

Sidel filling machine.

I like it as it is easy to transport, easy to install, it is economical, easy to access has less maintenance and is more efficient.

What do you think will be the biggest change in the equipment you work on in the next five years?

I don’t think there will be a big change because they keep upgrading the machines all the time and also give us training on the updates.

Most challenging part of the job as a production line equipment FSE

What do you find most challenging when you are working on site?

The most challenging thing has to be the food because when you travel you don’t get your local food. I really miss banku and shito.

The equipment you install is for food and beverage production.

Are there particular health and safety rules you need to follow in terms of hygiene (when on site)?

Yes

Cip (cleaning-in-place) and Cop (cleaning-out-of-place) must be done and for that I wear gloves, a face mask, and a hair net.

Making a winner

What makes the type of field service engineer who is tomorrow’s senior engineer?

The ability to think outside the box.

How important is ongoing training?

It is vital to open your understanding.

How key is it to have a mentor and a good team supporting each individual engineer?

A mentor and a good team is very important as they can guide you to become someone better in the future.

New field engineers

What advice would you give to someone who has just started their first job as a field engineer? Or is considering moving into this field?

Any new person must have someone to contact when things get difficult.

Apart from a strong technical background, what are the two most important skills to have?

Able to make good interpersonal relationships.

Ability to learn from and teach others.

Further reading on a Production Line Equipment FSE

A US Navy veteran who installs and services baking production line equipment for Kaak North America

Responses