A Field Engineer’s Perspective on Reducing Downtime and Improving Patient Care

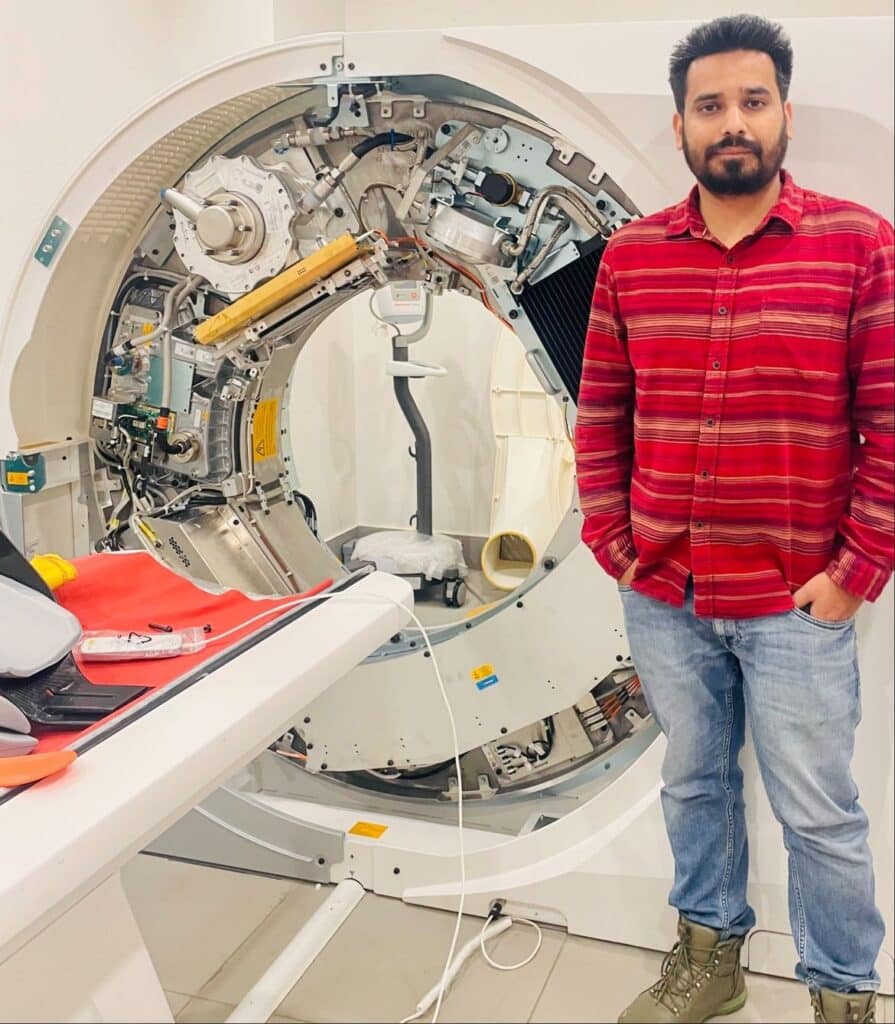

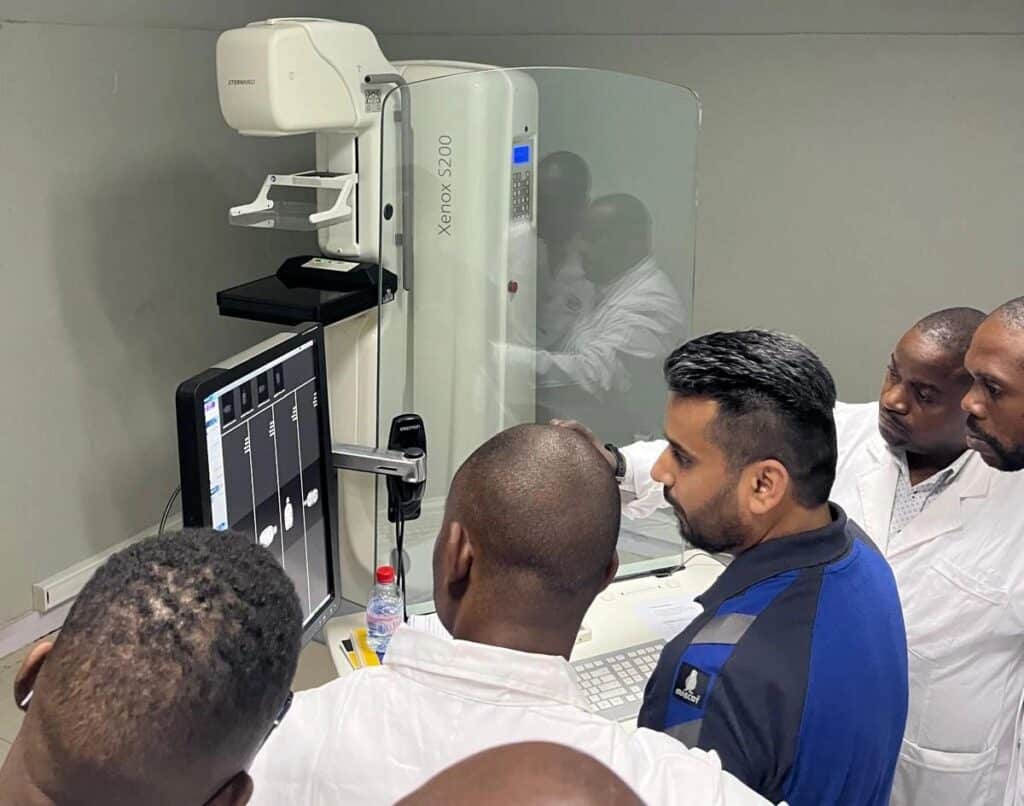

Reducing downtime and improving patient care are vital. This article gives one Field Engineer’s perspective on how to focus on reducing downtime and improving patient care. Varun Sharma works for SternMed GmbH and has moved from the role of Production and Service Engineer to Product Manager.

Reducing Downtime and improving Patient Care – one perspective

Introduction

Medical imaging systems like CT, X-ray, and Cath Labs are the heartbeat of diagnostic care. But keeping them running efficiently isn’t just the engineer’s job, it’s a shared responsibility between hospital staff and service professionals.

After 12+ years working across India, Africa, and now in Germany, I’ve seen how the smallest habits, good or bad, can drastically affect system uptime improving patient care.

This article is a simple, experience-based guide for radiology teams, biomedical staff, and hospital managers who want to reduce downtime, save costs, and improve patient outcomes.

What Do Field Engineers Actually Do?

Most people assume we’re just “repair guys.” Yes, we fix machines, but our bigger role is in preventive maintenance, calibration, safety testing, and early diagnosis of hidden issues. We keep systems aligned, compliant, and reliable.

When hospital teams collaborate with us, from timely reporting to simple maintenance habits, the results are faster resolutions and far less downtime improving patient care.

The Most Common (and Preventable) Issues to Help in Improving Patient Care

What are the most common, and usually preventable, issues. Here are some of the usual suspects I encounter on service calls.

Poor ventilation or dusty environments

Overheating and contamination lead to shutdowns and artifacts.

Forceful handling of components

Yanking cables or pushing gantry parts can lead to alignment issues.

Skipped warm-up cycles

Especially dangerous for X-ray tubes as it affects life and image quality.

Ignoring early warning signs

Error codes or odd noises are your system’s early SOS signals. So, it is important not to ignore them.

Five Daily Habits Towards Improving Patient Care

These five daily habits go a long way to avoiding preventable issues. These don’t require any technical skill, just consistency.

- Follow proper startup and shutdown sequences.

- Keep the equipment room clean and well-cooled.

- Report unusual behaviour or noises immediately.

- Log recurring error messages or slowdowns.

- Avoid stacking items or placing heat sources near the system.

How to Talk to Your Field Engineer so Together Improving Patient Care

If you talk to your field engineer then they can help you better. Remember:

“Clear communication = faster service.”

There are three key things you can do.

Be specific

Note the exact time and error code when an issue occurs.

Evidence

Take photos or screenshots when possible.

Coordination

Assign one contact person in the department to coordinate with us.

Why Preventive Maintenance is Your Best Insurance in Improving Patient Care

Preventive Maintenance (PM) is not downtime, instead think of it as uptime insurance. Preventative Maintenance (PM) can achieve the following:

- Catches early signs of failure;

- Ensures your system stays compliant and calibrated;

- Extends equipment life;

- Saves on costly emergency breakdowns.

If possible, try to schedule PM during off-peak hours or plan ahead with your service partner for a time when you know it will be less busy.

Know Your SLA (Service Level Agreement)

Not all service contracts are the same. It’s important to know what’s covered. For example, can you answer the following questions?

What are the response times? (e.g., same day or 24–48 hours)

Are spare parts included or extra?

What is the frequency of Preventative Maintenance (PM) visits?

What is the remote support availability?

Knowing the answer to these, helps you escalate efficiently and avoid unexpected costs.

Stay Informed, Stay Ahead

Modern imaging systems often give you early warnings. A well-trained operator can spot these alerts before they become system failures.

I always recommend periodic refresher training whenever new staff join or equipment is upgraded. It’s a small investment that pays off massively in system reliability.

Final Thoughts

As field service engineers, we’re not just fixing machines but we’re partnering with you to keep your diagnostic services running. With a bit of teamwork, we can reduce downtime, improve system longevity, and ultimately ensure better patient care.

If your system starts acting up or if you want to revisit how your team can better support imaging equipment health, I’m just a message away.

Let’s work together to keep your systems running and your patients moving.

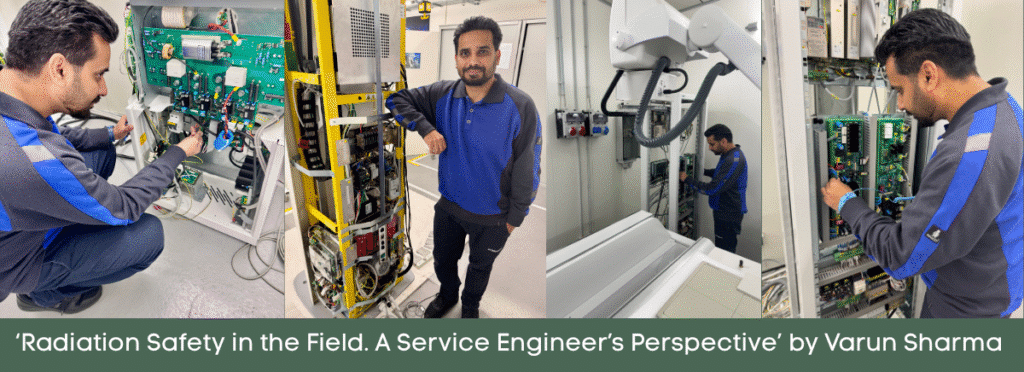

Varun Sharma, Healthcare Technical Professional – CT, X-Ray

Based in Friedrichshafen, Germany

With over a decade of experience in the medical imaging industry, I specialise in servicing, maintaining, and producing CT scanners, all X-ray medical equipment, and ultrasound and MRI systems. Since 2011, I’ve been dedicated to ensuring high-quality healthcare solutions by combining technical expertise with a commitment to reliability and precision.

Currently working as a Product Manager, I focus on optimising processes, troubleshooting complex systems, and supporting the seamless operation of life-saving medical technologies. My role bridges technical problem-solving and production efficiency, contributing to innovations that positively impact patient care.

Let’s connect to discuss ideas, share insights, or explore collaboration opportunities in the medical technology field.

Email: er.varunvicky@gmail.com

Further reading

How to educate on the importance of scheduled preventative maintenance

Spotlight on the work of a Technical Manager Dental Equipment

The Intentional Field Service Engineer 2nd Edition

The Intentional Field Service Engineer 2nd Edition

Responses