Being a Biomedical Engineering Manager

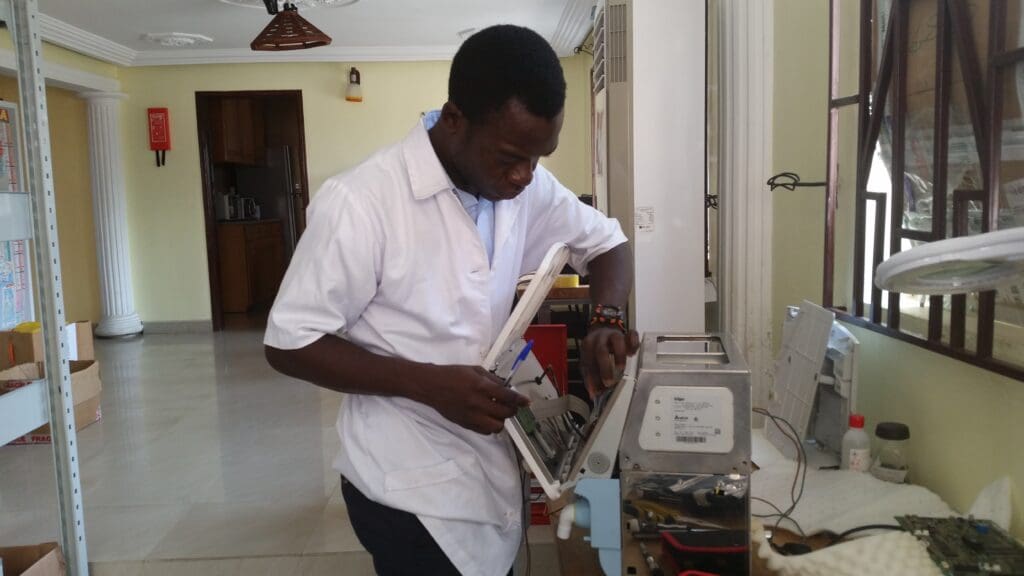

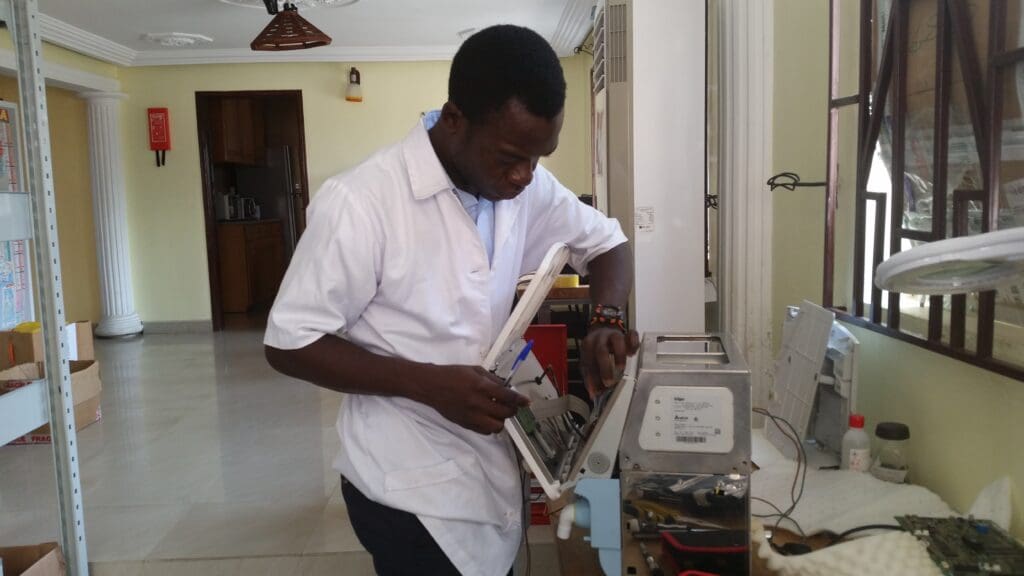

Alex Nii Nortey Dowuona is a hospital Biomedical Engineering Manager working in Accra, Ghana for Grupo Empresarial Electromedico

Path to being a Biomedical Engineering Manager

Could you give a brief description of your background and what led you to study and work in biomedical engineering?

I studied Mathematics, Physics, Chemistry, and Biology at High School. After that, I enrolled in a computer training school, where I studied graphic designing (Corel and Adobe Photoshop designing suites). With this knowledge I began working partly in event management services where I designed stickers, billboards, and invitation cards. Nothing medical at all. In this same year, I was preparing for tertiary education.

I come from a family where all the men worked either as civil or electrical engineers. I loved biology as a course during high school and I was ready to handle any programme with biology as its basis from medicine to zoology.

So, Biomedical Engineering was the ideal combination for me.

Were you interested in science and engineering when you were a child?

A big yes. As a child, I remember we built almost every heavy-duty machine with empty milk tin cans and cut out its tyres from old rubber slippers. I also remember I fed dragon fly larva with mosquito larvae in an old broken onion bulb lamp where I would hang it from a tree and watch the feeding process. That excited me so much.

Hobbies and Interests

Do you have any hobbies or interests which are technical or involve using your hands for detailed and precise work?

Carpentry. My dad is a carpenter. He designed wooden moulds for concrete works. I assisted him at his work bench. Taking measurements for accuracy and precision is the first steps of woodwork to avoid wastage.

I respect wood as a material a lot. When treated well enough it could be a substitute to solve a technical problem but of course it is the least tolerant.

You have also studied graphic design. Does this help you in your work as a Biomed?

Very much in three ways:

Firstly, graphic design like biomedical engineering involves a lot of detailed and precise measurement.

Secondly, in my current position, I am unofficially in charge of publicity. I need to advertise my firm to the world. I designed the banner for my office, and it earned me some credit from my employers.

Thirdly and indirectly, I can describe simple or complex technical problems just by designing or doing very good and elaborate editing on the problem photo. This helps my technical director or equipment manufacturer to get a vivid understanding of the problem.

Has there been a particular person who has inspired you?

Oh Yes. Professor Frimpong Boateng He started out with dreams of being an engineer and later ended up as a heart surgeon. And later set up the first cardiothoracic centre in Ghana.

Typical day as a Biomedical Engineering Manager

What’s your typical day like?

Given my current position, it’s always a happy day when my two team members appear. Then, I have the time to really plan out the day both technically and administratively. Client satisfaction is the goal for each day.

How much of your time is spent hands-on and how much with admin, managing and other tasks?

If we are not implementing our planned preventive maintenance, I spend close to four hours with early morning checks with my team. Roughly an hour of every day is spent giving troubleshooting tips to my team so that they can get things repaired. Then the rest of the day is for replying to emails, processing work orders and scheduling maintenance.

Which other parts of the hospital give you support?

As a contracted engineer, client satisfaction is our goal. Because of this we make every effort to impress the client with our technical independence. Equipment users offer better support by detailing how a particular problem arises which in turn becomes a great tool in your troubleshooting or repairs.

Equipment used as a Biomedical Engineering Manager

What are the specific pieces of equipment you and your team maintain?

We service a range of equipment all the time.

Life Support

Anaesthesia Equipment

Patient monitors

Cardiac monitors

Capnographs

Ventilators

Operating theatre beds (Electric and Manual)

Operating theatre lamps

Volumetric Infusion Pump

Syringe Pumps

Central Sterilization Department (CSSD)

Washer Disinfectant Machines

Steam Autoclaves

Most challenging part of the job as a Biomedical Engineering Manager

What do you find most challenging when you are working?

There are three big challenges in my role:

Urgent repairs – When life support equipment malfunctions while a procedure is ongoing, and you don’t know the cause of the problem immediately.

New equipment – When you install a new piece of equipment, and it fails almost immediately. Then, an impression is created in the users’ mind about the quality of the equipment even though it’s new and of good quality. We then need to win the users’ trust and to assure them of a good after sales service or even warranty extension.

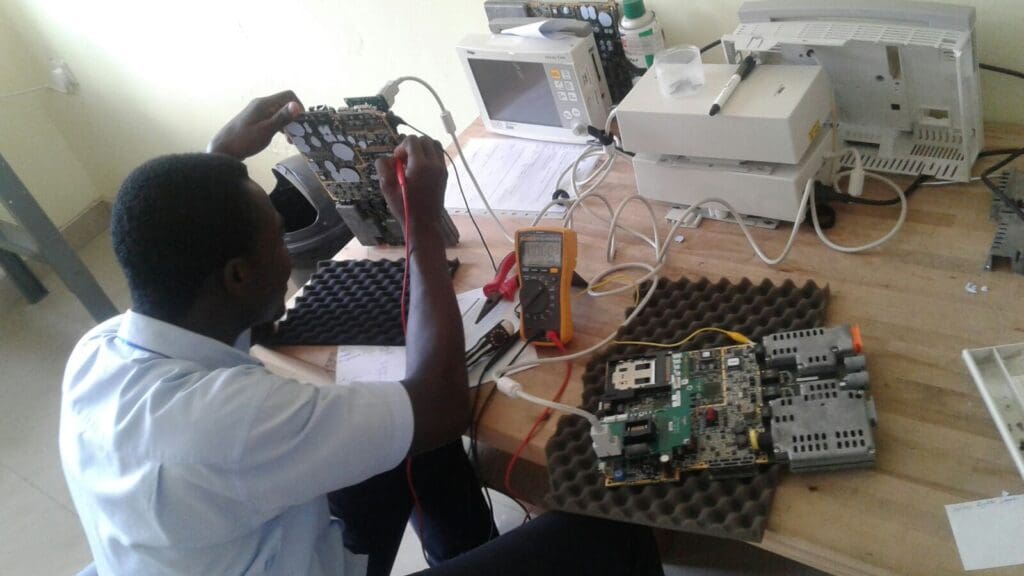

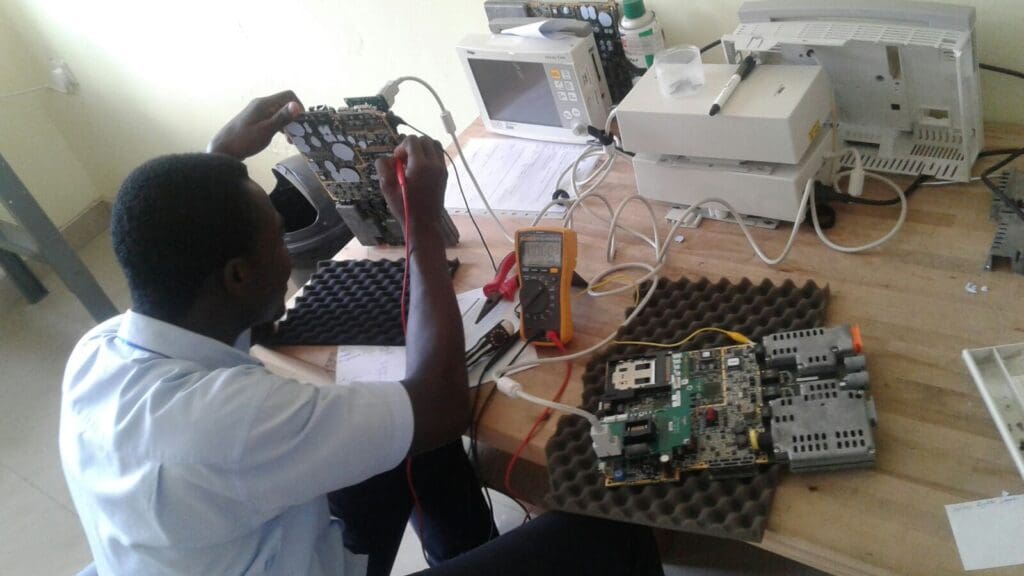

Remote assistance – When I need to remotely assist a fellow engineer to troubleshoot complex circuits boards or equipment.

Have you ever arrived on site and found that it was much easier than you expected? For example, did you ever need to simply switch on a machine.

Yes, I had this experience once. The user was used to turning the equipment ‘ON’ from the standby mode. So, when the main switch was turned off after preventive maintenance, they reported the machine as not working the following morning.

Challenging factors

Has your role ever uncomfortable because of heat, cramped spaces, bad lighting, power outages etc?

Wow! Let’s tackle this in two categories.

Heat, cramped spaces, and bad lighting

Normally when there is a cramped space around large equipment that needs maintenance, you will automatically have poor lighting followed by heat depending on how it was initially installed.

A lot of times the installer from an equipment manufacturer is always after giving a good finish to their job, but provisions for maintenance are not always their top priority. For some equipment that I deal with currently I have to access the top cabinet by going through the ceiling just to change a filter or check the state of the extractor fans. Those works were easier for me to do when I was younger some three years ago. I was able to sneak in, out and go all around the machine like a gecko. Of course, I put on a little weight and my subordinates are better at sneaking around the big equipment.

Another instance is that users are only interested in viewing some parameters such as temperature and pressure right on the user screen which is very comfortable. But as an engineer I sometime have to get the manometric readings right on top of the boiler or heater and its worse if you have to calibrate.

Power outages

I don’t have a good feeling when power goes off abruptly, especially when we are connected to the national grid. UPS doesn’t do well with 3 phase devices that have heaters/boilers. Power outage is quite a challenge and a nightmare for equipment. You cannot be totally sure power won’t go out, but when the power distribution services alert power consumers on scheduled outages, we can save equipment from power problems at least.

Secondly voltage monitoring and security devices have to be present always to help alleviate power related problems.

Making a winner

You belong to The National Society of Black Engineers and The International Association of Engineers . How has being a member helped you?

Honestly, it’s been so long since I heard of them. During our course of study, we were advised to belong to some of these international organizations and that it could favour your chances of getting a job. The truth is all the successful interviews that got me jobs didn’t require these international recognitions.

What are the ideal qualities to be successful working as a Biomedical Engineer in a hospital?

The hospital is a complete set up, and because of this a biomedical engineer cannot limit him/herself to just the theatre or ICU.

Experience has taught me to be diverse. I had to quickly upgrade myself from troubleshooting simple electronic circuit boards to handling 3-phase equipment. And how did I do it? Well, I worked in five different ways:

Firstly, I downloaded and watched engineering videos from YouTube that talked about testing simple electronic components, troubleshooting skills, electrical wiring, induction motors etc.

Secondly, I always keep myself up to date with the equipment manufacturers’ yearly calendar training programmes. Mostly, I do this on-line.

External exposure to work and training. I had a formal 3-month training in our parent company in Madrid and Barcelona. I also joined a team of engineers on medical equipment installations in Angola.

Sharing ideas and suggestions from fellow engineers is a must for me. No man is an island.

Good Engineer-Client relationships help and my current position demand more of this.

Communication skills learnt as a Biomedical Engineering Manager

As well as specific technical skills, how important are people and communication skills?

As a biomedical engineer, users of the equipment that you service are your best friends. To be honest, users don’t know about the electrical or mechanical aspects of the machine, but they can help with about 90% of the troubleshooting. They can tell you what they have seen and heard, as well as what they have done. It is prudent to maintain a very cordial relationship with users/clients, and then you can ask questions to help you fix the equipment.

How important is ongoing training?

Training is vital, when well organized in-house or externally, it really boosts the confidence of engineers when problem solving.

New Field Engineers

What advice would you give to someone who has just started their first job as a biomedical engineer?

Congratulations!

And welcome to the engineering fraternity.

If you find yourself in the maintenance section, then the following should really help you

Always use manufacturer documents, example service and user manuals in attending to equipment.

Equally get yourself acquainted with the user mode of the machines and not only service modes.

Remember user knowledge is a primary introduction to service knowledge.

Update yourself with new technologies and software.

Some Equipment Manufactures have yearly online training calendars for software training, service training and user/refresher course training. You need to contact necessary authorities to get you enrolled for such training.

Always upgrade upon your current troubleshooting skills. Troubleshooting skills mature alongside your years of experience.

Use web-based applications like YouTube to watch equipment servicing videos, how to test electronic components and how they function.

Expand your skill base

Get experimental knowledge on wiring (Domestic or Industrial). Not a necessity but it will not leave you out of the conversation when the electrical engineers are having a chat.

Knowledge in plumbing is very important if you will be handling dental units and other equipment that work with fluids.

Know your measurements and relevant units. This is not space science, but you need your measurements. I have encountered people that I had to make them understand that a foot long is actually the size of their feet and they needed only three for a yard and that is the length of their USB cable phone charger. You cannot do without measurements. So, get acquainted.

Never limit yourself to the ICU, Theatre, dental and eye clinic. You are equally competent as the other service engineers in the gas plants, welders, electrical engineers, plumbers, and carpenters.

Keep a cordial relationship with equipment trainers/superiors. You don’t always need to send them technical assistance emails. Get a copy of their regional calendar and send them good wishes on festive days.

Troubleshooting as a Biomedical Engineering Manager

What advice would you give for:

Fixing a critical piece of equipment surrounded by medical staff and patients?

If the equipment can be moved to a nearby room, it is better to quickly troubleshoot from there.

If not, first ask how many minutes can they give you? At least ample time, like 10 minutes. This duration will be enough to quickly troubleshoot and solve equipment with power issues like a bad fuse or breaker. If it arises from the PCB within the piece of equipment, you might have to decommission quickly and replace with a standby. In all instances just keep cool, be smart and don’t panic.

What advice would you give for:

Answering questions whilst working on a piece of equipment?

This is always a difficult situation. In these situations, I normally allow my technicians to work while I stand back and answer questions while keeping an eye on them as they solve the problem.

What are your tips when the usual troubleshooting hasn’t worked?

So, in a lot of cases the mechanical parts remain undamaged. But when PCBs (Printed Circuit Boards) go ‘OFF’, you either try with another or check the warranty status of the machine and get another from the manufacturer if it is still under warranty.

Tips:

Changing Passive components like fuses, resistors, capacitors are OK. But for damaged Active components like a diode or transistor I recommend a new one.

If your usual troubleshooting skills don’t work, no need to worry because you found out how not to troubleshoot that particular circuit board.

Keeping a good work life balance as a Biomedical Engineering Manager

How do you keep a good work life balance?

I possess a level A1-A2 conversational level in Spanish language which is just enough to keep the conversation going.

As well as that, I play in a local football team; we don’t have plans of playing in the Local Premier League, African Championship or World Cup but the fan base is enough to keep you busy on weekends just before dusk.

Reading books that have been made into movies is another interest, J.K Rowling’s Harry Potter, George R.R Martin’s Song of fire and Ice, George Orwell’s Animal Farm. And I also like to spend time with my family.

Iberica De Mantenimiento Ghana Limited

I work for Iberica De Mantenimiento Ghana Limited (IBERMANSA-Ghana Ltd). It is an International Healthcare Technology management company specialised in the medical equipment planning, procurement, installation, repair and maintenance for medical facilities in and across Ghana and beyond. It is part of Grupo Empresarial Electromédico (GEE) a holding company located in Spain. GEE has over 35 years of successful execution of integrated healthcare projects, from equipment maintenance to services management.

Projects are coordinated and managed by a highly professional team with diverse skills and extensive industry knowledge. The Team comprises professionals specializing in equipment and medical systems, design and engineering, logistics, procurement, and project management. It is the objective of the company to bring optimal healthcare technology to clients throughout the nation and beyond.

Responses