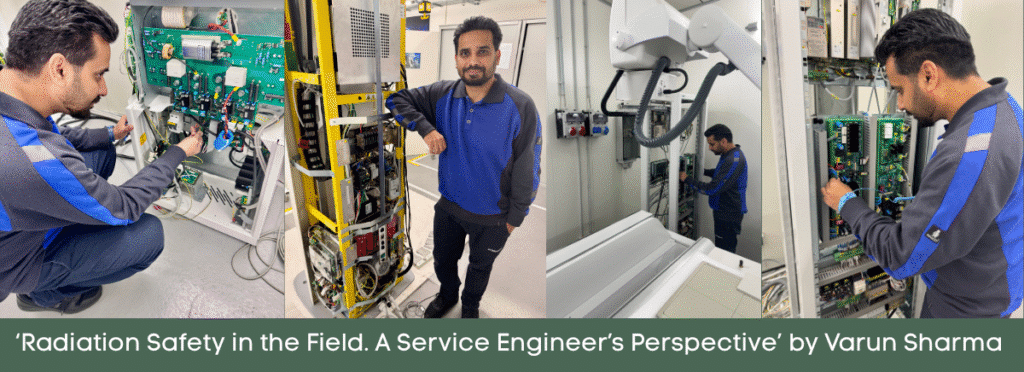

Radiation Safety in the Field: A Service Engineer’s Perspective

Radiation Safety is critical not just for medical staff and patients but also for the field service engineers who service and maintain the equipment. In this article, Varun Sharma shares his perspective on radiation safety in the field. He shares the practical lessons he’s learned, and why it matters not just for field service engineers like him, but for the hospitals and patients who rely on these technologies every day.

Varun Sharma works for SternMed GmbH and has moved from the role of Production and Service Engineer to Product Manager.

Radiation Safety: how to be safe in the field

Introduction

When people think of radiation safety in healthcare, the first images that come to mind are usually doctors in lead aprons or radiographers standing behind protective glass, guiding patients through CT scans or X-ray procedures. Rarely do they consider field service engineers. These are the technicians who install, calibrate, and maintain these machines. They are often working behind the scenes yet exposed to the same invisible hazards.

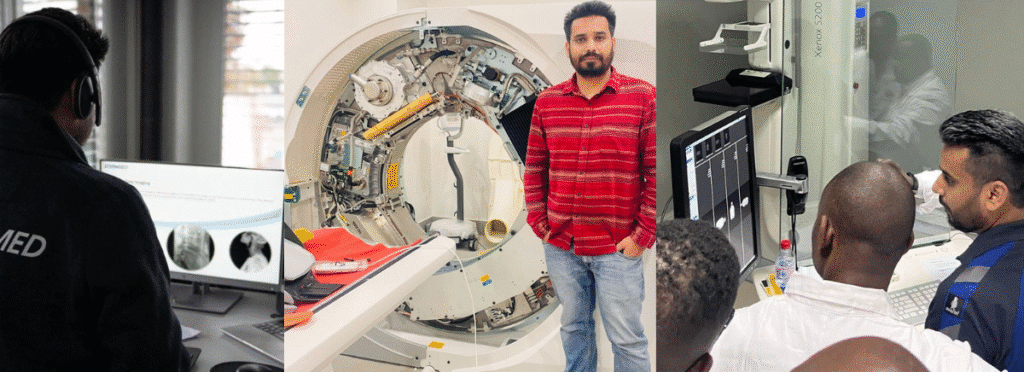

I’ve been one of those engineers since 2011, traveling to hospitals across India, Nepal, Africa, and Europe to ensure that critical diagnostic imaging equipment functions safely and reliably. My days are a balance of precision, technical problem-solving, and constant vigilance. Every service call presents its own unique challenges: a CT scanner that needs recalibration, a Cath Lab system undergoing testing, or an X-ray machine installation where shielding isn’t yet complete. In each case, the principles of radiation safety guide every step I take.

The invisible risk

What makes this role particularly demanding is the invisible nature of the risk. Unlike clinical staff, who operate within controlled safety protocols, service engineers often work in situations where interlocks are disabled (i.e. a safety mechanism has been deliberately bypassed), shielding is incomplete, or test exposures are necessary. It’s a reality that requires both technical skill and an unwavering commitment to safety. These are lessons I’ve learned over fourteen years in the field, reinforced by certifications like the AERB Radiation Safety Officer (India, 2016) and Strahlenschutzkurs (KIT, Germany, 2023).

The overlooked role of the Field Service Engineer

Unlike clinical staff, field service engineers often encounter machines in states where safety systems are bypassed. This may be during installation, calibration, or troubleshooting. Interlocks may be disabled, shielding not yet completed, or test exposures required to validate system performance.

In these moments, we are uniquely vulnerable. We don’t have the same structured workflow as radiographers; instead, we must combine technical expertise with strict personal discipline to minimize risk. It’s a responsibility that demands both technical skill and safety awareness in equal measure.

Core Principles That Guide My Work

From my earliest days in the field, three principles have guided my approach to radiation safety.

ALARA (As Low As Reasonably Achievable)

Reduce exposure time, maximize distance, and use shielding wherever possible.

Dosimetry and Monitoring

Wearing a dosimeter is not a formality, it’s a necessity for tracking cumulative exposure.

Protective Equipment

Lead aprons, thyroid shields, and protective glasses aren’t only for clinical staff; service engineers must use them too when required.

These basics sound simple, but in high-pressure service environments where downtime is costly and hospital staff are eager for quick fixes discipline is what keeps us safe.

Field Lessons Learned Since 2011

After more than a decade in the field, some lessons have become second nature. These are the four main ones.

• Always verify that equipment is in standby mode before servicing.

• Double-check warning lamps and interlocks as they exist for a reason.

• Plan exposure tests in advance to minimize repeated runs.

• Work as a team with radiology staff; clear communication avoids unnecessary risks.

These small but vital practices have protected me in countless service calls, and often more than any technical manual ever could.

Beyond Servicing: Designing Safe Rooms

Radiation safety begins even before a machine is switched on. Over the years, I’ve also been involved in planning room layouts for CT, X-ray, and Cath Lab installations.

A proper layout isn’t just about fitting a system into available space; as it determines:

• The effectiveness of radiation shielding in walls, doors, and windows.

• The workflow efficiency for staff and patients.

• The hospital’s ability to meet regulatory compliance standards.

When designing layouts, I focus on aligning equipment placement with shielding requirements, ensuring operator consoles are located in safe zones, and minimizing scatter radiation risks. In this way, service engineers play a quiet but crucial role in shaping safe clinical environments.

Certifications that strengthen my practice

Radiation safety requires more than experience; it demands formal training and certification. I have been fortunate to receive recognition in both India and Germany:

• Radiation Safety Certification for Service Engineers in Diagnostic Radiology

Atomic Energy Regulatory Board (AERB), India – Apr 2016

Credential ID: RSDR/2016/445

• Strahlenschutzkurs für Wartung und Erprobung von Röntgeneinrichtungen mit Qualitätssicherung

Karlsruhe Institute of Technology (KIT), Germany – Jul 2023

These certifications not only validate my knowledge but also expose me to two distinct regulatory frameworks: AERB in India and Strahlenschutz in Germany. Together, they provide a broader perspective on how radiation safety is enforced globally.

Challenges we face as Engineers

Radiation safety in the field isn’t always straightforward. Some challenges I’ve faced include the following three.

• Pressure to restore equipment quickly, leading to the temptation to bypass safety steps.

• Hospitals with varying safety cultures: some highly disciplined, others less so.

• Junior engineers lacking awareness, requiring mentorship to instil safe practices early.

In such environments, field service engineers must hold themselves accountable. Your own safety cannot be delegated: It’s a personal responsibility.

Why It Matters

Radiation exposure is invisible, but its long-term risks are undeniable. Practicing safety ensures not just compliance, but also a sustainable career free from preventable health risks.

Hospitals benefit too as an engineer who prioritizes safety reinforces the culture of protection for everyone on site, reducing liability and improving trust. And for junior engineers entering the field, seeing safety modelled as a priority helps set the standard for the next generation.

Conclusion

After 14 years in diagnostic imaging service, one truth has remained constant: the best engineers are not only problem-solvers, but they are also safety leaders.

Radiation may be invisible, but our duty is clear. Every time I walk into a service room whether in India, Nepal, Africa, or Europe, I carry with me not just my tools, but the mindset that safety always comes first.

Further reading

Spotlight on a Woman working as a Hardware Installation Engineer

Responses