Spotlight on a multi-industry mechatronics field service engineer

This article focuses on a mechatronics field service engineer who has experience in different types of engineering and different industries and illustrates that a good engineer can turn their hand to understand and fix anything.

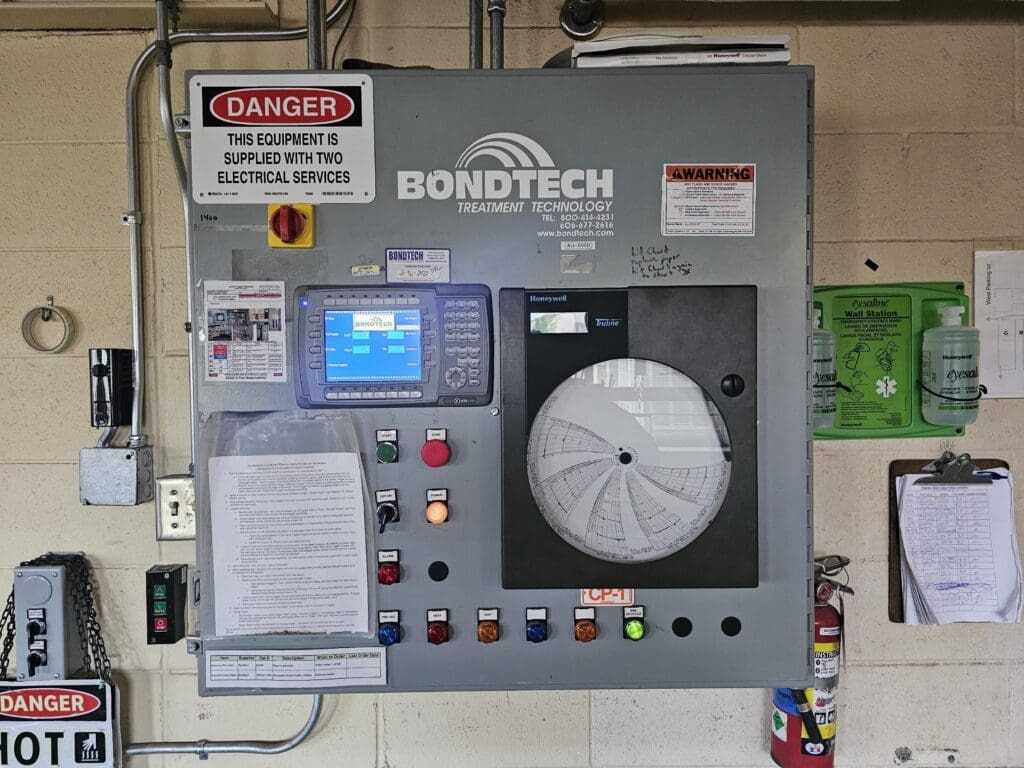

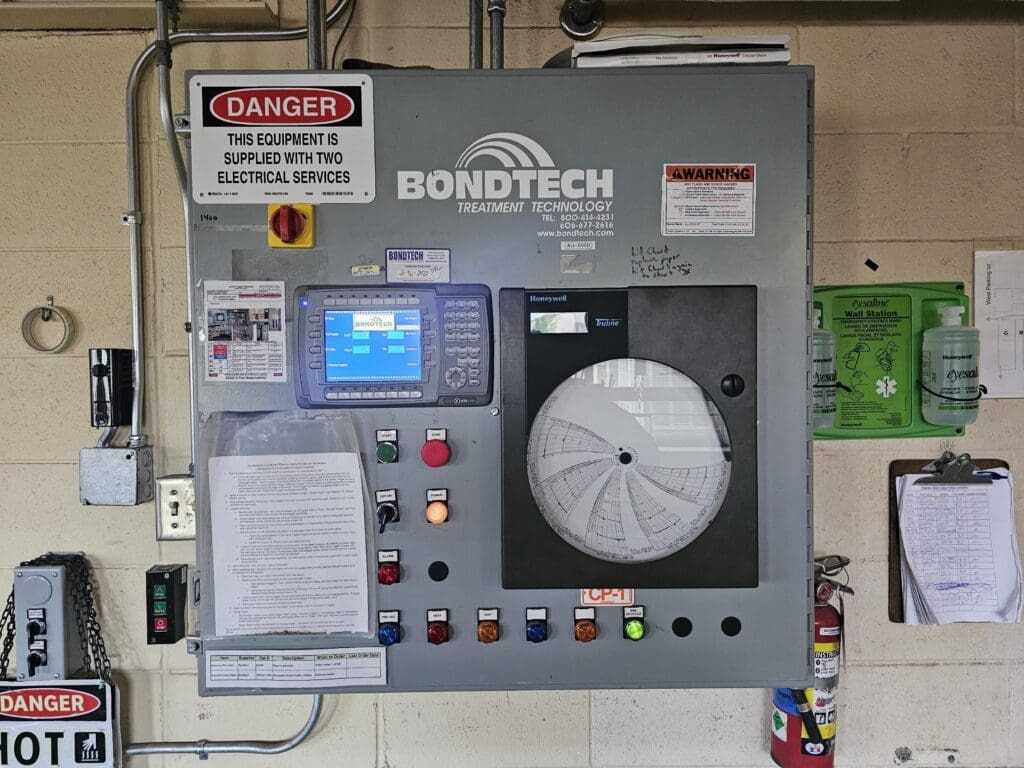

Walker Pollitt has experience with industrial, electrical, mechanical and software engineering. From 2005 until 2020 he ran his own field engineering service company. At the moment, he works with Bondtech Corporation who are a leader in industrial autoclaves a.k.a steam sterilisers.

A Life in Industrial Electrical and Mechatronics Field Service Engineering

Background

Why did you decide to study Computer Science and Information Systems? Was there a childhood interest which led to this?

I was always encouraged and interested in technical things. I was raised (brought up) by my grandparents who would buy me old radios and TVs and let me take them apart to see how they worked. Then, the Engineer’s Mini Notebook by Forrest Mims from Radioshack was a game changer. Because of that, I finally learned about circuits, how they worked, and how to etch my own circuit boards.

Were any of your teachers inspirational?

I had several inspirational teachers, but they were all English or Art teachers. Unfortunately, I didn’t receive much in the way of science or technology encouragement in school.

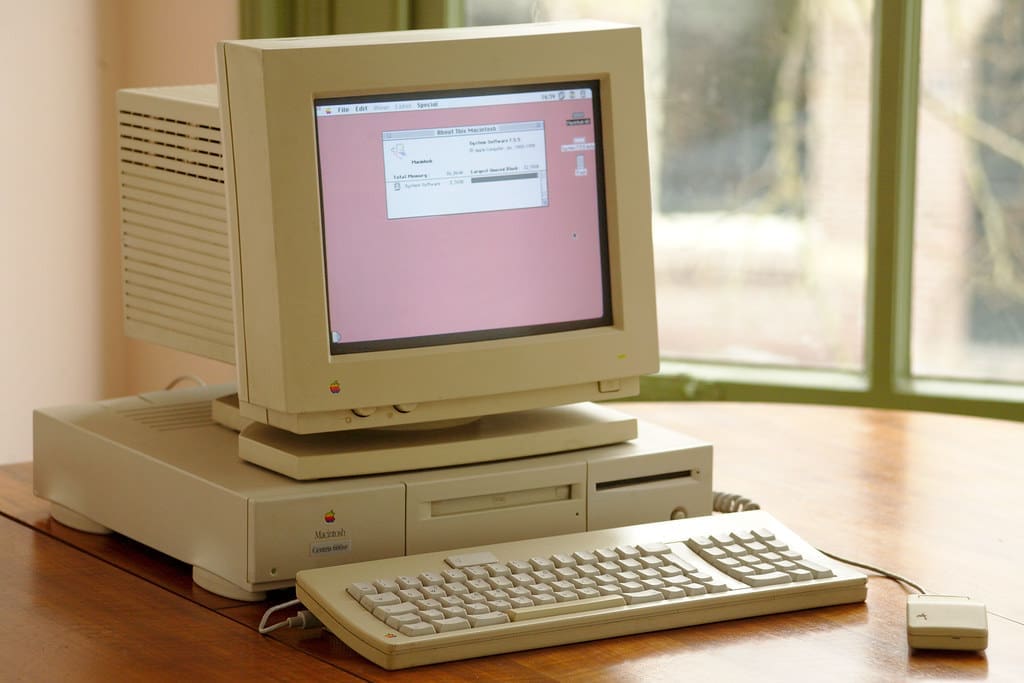

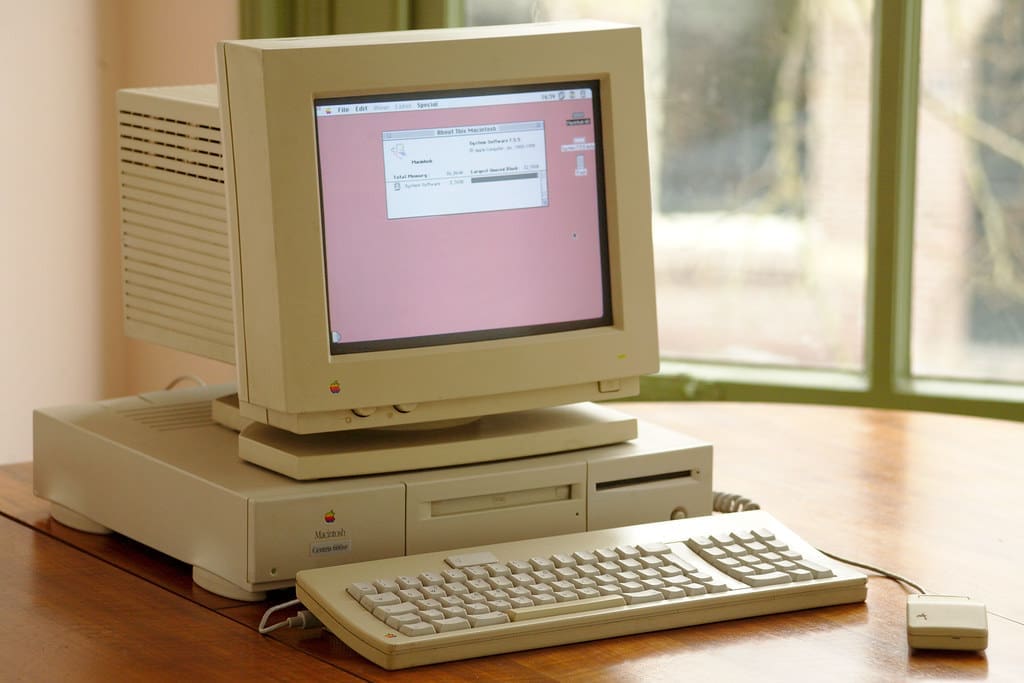

How old were you when you first used a computer? Which one was it and what did you do?

I was 15 when I got my first computer in 1993. It was a Macintosh Centris 660 AV. It had 3.5” and 5.25” floppy drives and a colour laser printer; and as well it allowed speech control. I could open files or dictate, and it was very reliable. My neighbour had an intel 486SX based PC and would program paint programs for his kids. Also, he taught me chess.

Typical Week

What’s your typical week like?

Typically, I travel the country inspecting industrial pressure vessels. These are mainly medical waste sterilizers that are steam powered.

I started this month in Houston, Texas at a wood pressure treatment facility replacing door bearings on a vessel from the 1950s. They don’t have many replacement parts for things that are that old, so I had to fabricate quite a few of the pieces that needed replacing.

I then travelled over to Fayetteville, Arkansas to the VA (veterans) hospital to replace door bearings, steam inlet valve, safety relief valves, safety interlocks, and calibrate the system to ensure safe and proper functioning. I supervised the R stamp code welders who replaced the door locking wedges, and the Non-Destructive Testing to check for cracks or weak spots in the vessel. These things can get up to 400psi, and they are typically 8’x20’.

How much of your time is spent ‘hands on’ and how much on admin and new business?

I spend most of my time hands on as I prefer it that way. I do a fair amount of administrative work as well. For example, I plan my own travel itinerary, write reports for the home office, and the customer reports. Then as well, the calibration records need updating, customers need training on maintenance schedules and safe vessel operations, and of course updating the photo database. I take LOTS of pictures!

Client relationships

How do you quickly establish a good relationship with a new client?

Customer service has always come easily and naturally for me. The secret to quickly establishing a rapport with the client is actively listening to them. I take in the big picture. Then I process all the information, and logically deduce the best way forward. Is my client the operator? The floor manager? The owner of the company? What are they wearing? Hands dirty? Wearing clean clothes, or dirty work boots? They all require handling in a different way.

Challenges

What is the most challenging part of your job – technical side, the customers, or logistics?

Logistics is definitely the one stumbling block in my day-to-day job performance. The person I submit my recommendations to, doesn’t always order what I requested, or sometimes I’m following the last person to visit the site and they ordered the wrong parts. Plus finding the time to pursue all the certifications I would like to have, as well as scheduling down time at home is difficult to juggle.

How do you deal with working in confined spaces and/or on the floor?

I don’t find confined space, on the floor, or getting dirty/wet an issue. Actually, I find it extremely satisfying to look back on a really hard dirty day’s work and think:

“I got it done, I finished the task, and so I got the client back up and running again”.

There is nothing else quite like it.

What has been your most challenging job to date?

Most challenging job to date was probably the repair in Texas of the old 1950s vessel. It was extremely corroded. What should have been a three-day job at most, was a seven-day job. Therefore, I didn’t get to go home between jobs. That was tough. The longest I have been away from home so far.

How do you explain technical issues to non-technical people?

I use analogies to explain technical things to non-technical people. PC RAM is like the speed limit sign on the highway, but you can’t exceed it. That one is one of my favourites. It depends on the client though. Sometimes I use gardening, or car engines as examples.

Technology changes in mechatronics field service engineering

How have you seen systems and technology change since you started work?

I have seen technology become more automated. It has become more geared towards enabling non-technical people to do technical jobs. Like AI for example… I can use it to generate lines of code, or a work of art that I otherwise wouldn’t be able to create.

How do you stay up to date?

It’s a challenge to stay abreast of the latest changes. Especially when I’m interested in so many diverse fields. I have customised my news feed to show me relevant articles of interest, and journals from technical society memberships also help.

How do you pass on your knowledge?

It’s easy to pass on knowledge. However, it’s hard to teach someone to be passionate. Getting someone interested in something is the easiest way to ensure they pay attention to what you are trying to impart.

What do you think will be the biggest challenges facing field engineers working with IT and computer systems in the next 2-5 years?

The biggest challenges I see coming down the road is lack of enthusiasm. I don’t know if I’m starting my journey into grumpy old man territory, or if subsequent generations really are caring less and less about most things in general.

Making a future star

What sort of personality traits and skills are ideal for working as a field engineer in IT?

The best personality trait for any engineer is curiosity. If you have a passion to explore and discover, the rest will come easily.

Apart from a strong technical background, what are the three most important skills to have?

The three most important skills are organisation, customer service, and caring. You must care about the finished product you are presenting to the world. You must be organised to complete tasks in the appropriate order. Treating the customer the way you hope to be treated is key to great customer service.

Why would you recommend this type of work to someone studying any sort of computer engineering at the moment?

I love my job because I love being the person who my clients depend on to accomplish the impossible. I had a co-worker tell me early in my career:

“It IS rocket science, because if it was easy to do, they wouldn’t need us.”

He meant something different than my takeaway, but it still was a critical turning point from passionate enthusiast to successful professional. So, if you like being the problem solver then I would recommend this path of the engineer.

Further reading about mechatronics field service engineering

Life of a Field Service Engineer who loves Italian technology

Responses