Olufemi O Makinde Marine Coating Inspector in West Africa

Chemical Engineer working as a Marine Coating Inspector

Olufemi O Makinde, from Nigeria, graduated in Chemical Engineering and began his career as a Senior HSE (Health and Safety) Officer. He then became a coating Inspector and has worked both on and offshore for Nigerdock Nigeria. Olufemi is currently working in Togo as the Lead Marine Coating Supervisor for Painting Corrosion Service, PCS.

Olufemi is a member of Nigerian Society of Engineers (NSE), Nigerian Society of Chemical Engineers (NSChE) and National Association of Corrosion Engineers (NACE).

Background

What led you to study chemical engineering?

From childhood, I initially planned to be a medical doctor. However, the plan changed before I finished my high school education when I decided to study chemical engineering and work in the Oil and Gas sector.

Do you like fixing things other than at work?

Yes. I do like fixings things most of the time.

Who is your mentor?

Mr Anné Eugene, my current boss.

Working as an HSE (Health and Safety) Officer

What did your job as an HSE Officer involve?

My job as an HSE Officer involved ensuring strict adherence to HSE principles and policies such that all activities were carried out in a manner that eliminates/minimizes the risks to employees, property, and equipment.

What skills did you take with you from this job?

Hard skills?

A thorough knowledge of Health and Safety rules and regulations. As well as identifying workplace hazards and control measures.

Soft skills?

Effective communication skills, and the ability to visibly show concern for others.

How can you educate all people to consider health and safety all the time?

Safety is as simple as ABC:

Always Be Careful. Avoid short cuts; it cuts life short.

If it is not safe, don’t do it.

Always protect yourself, others, and the equipment.

Offshore Coating Inspector

Can you describe the role of an offshore coating inspector?

The role of a coating inspector is to observe the technical aspects of a coating project. The coating inspector’s responsibility is to verify the coating specification.

How much does the weather delay you?

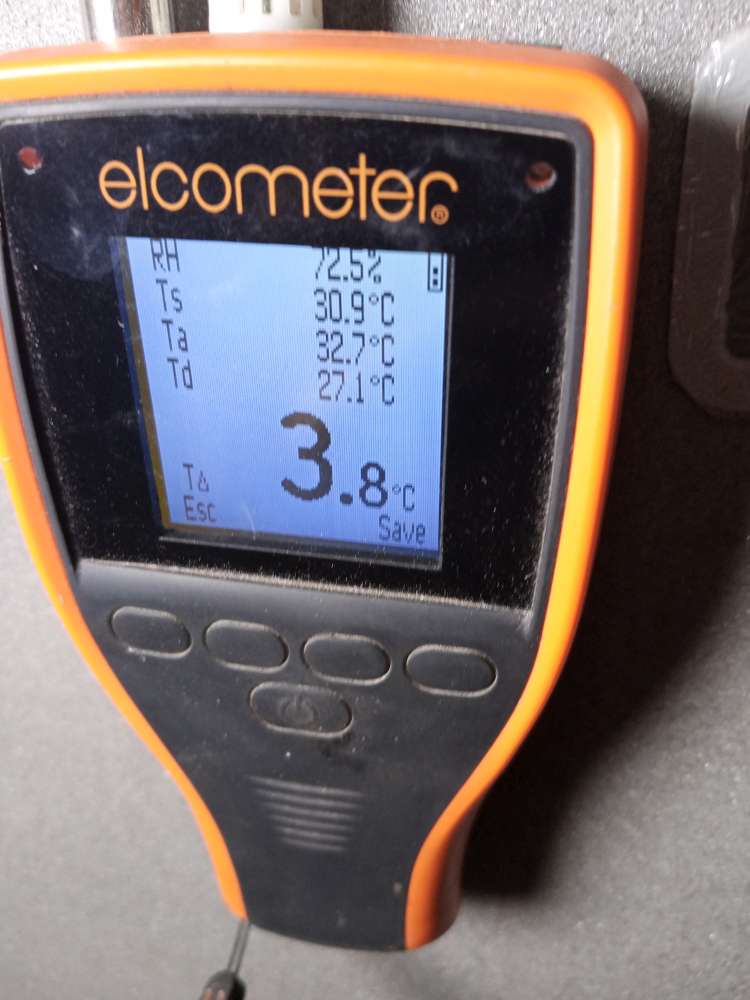

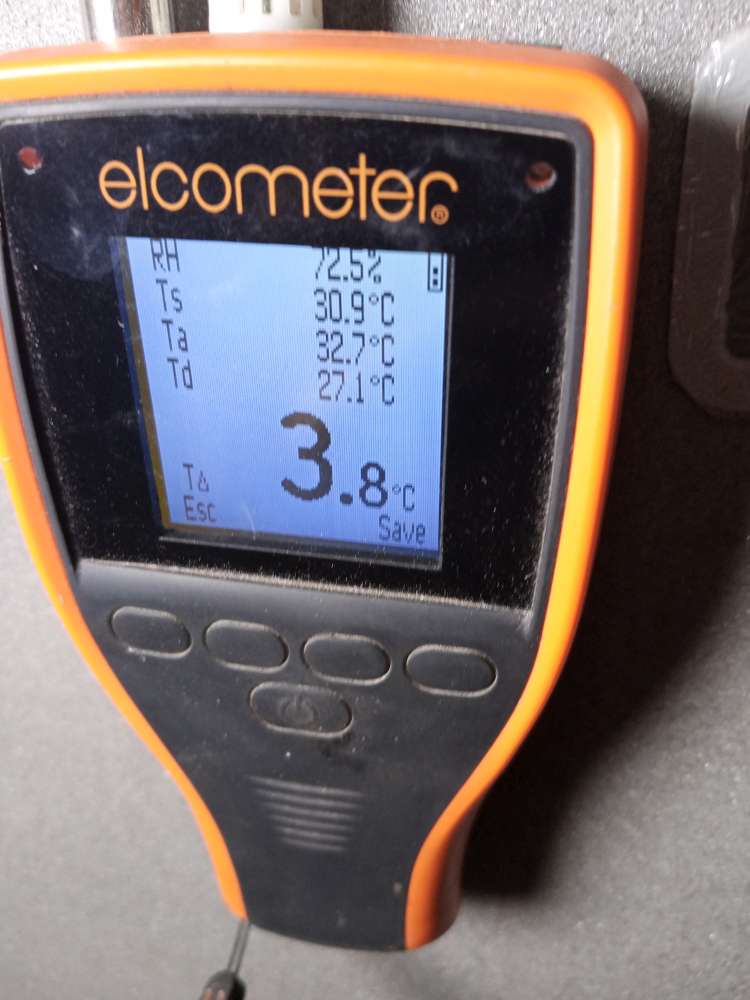

Outdoor coating activities are adversely affected during rainy seasons and when weather conditions are not within the specified parameters. Then there will be a need to wait for favourable weather (mostly advised by the coating inspector), this may well lead to a downtime.

On the other hand, there are engineering control measures for indoor activities. For example, a dehumidifier: this lowers the moisture content in the air and can also increase the air temperature. It performs best in an enclosed area and helps to control corrosion of blast-cleaned surfaces.

Typical day

What’s your typical day like?

I work on site doing inspections and tests, and in the office doing documentation and reporting.

Can you describe what you do technically?

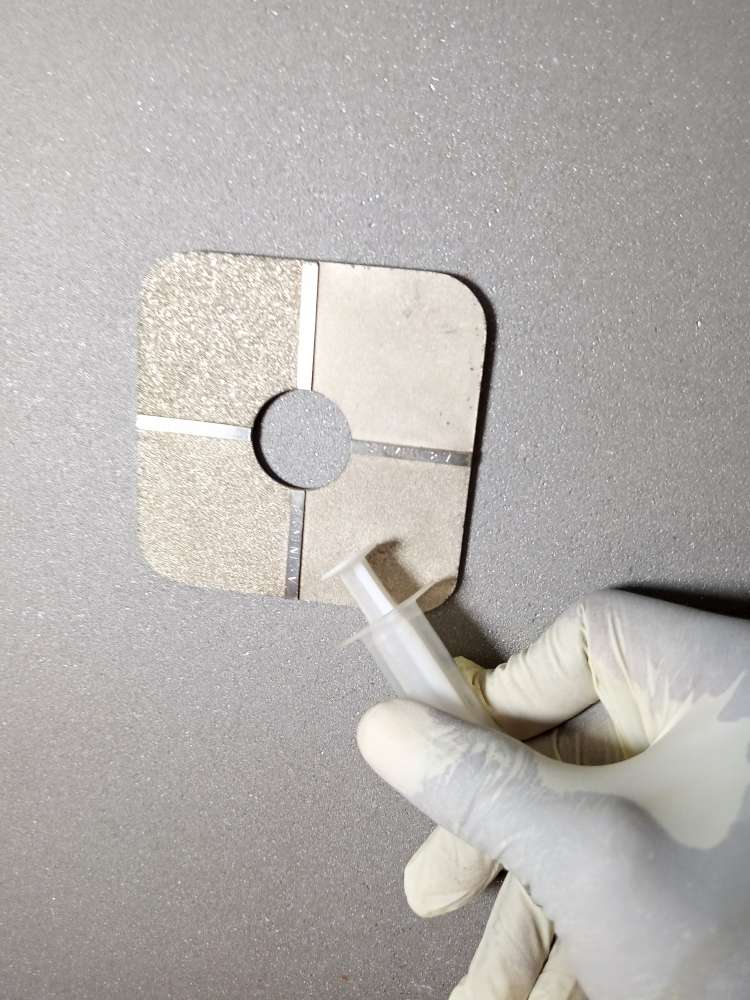

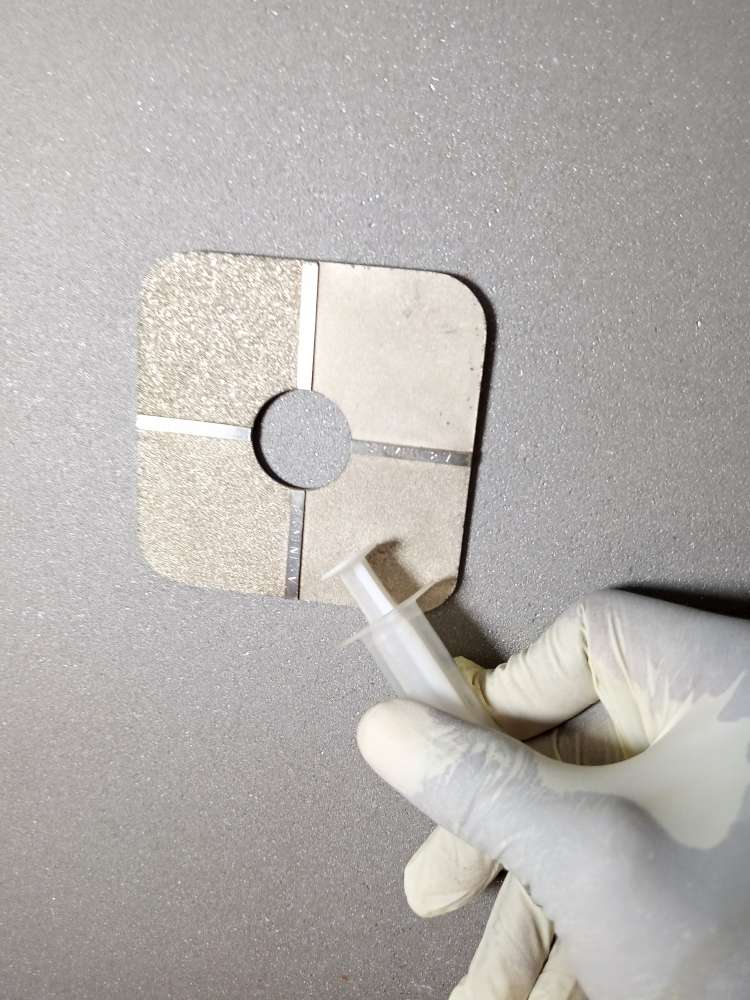

I observe and advise on the surface preparation required, record the atmospheric conditions at intervals, verify the quality of materials and equipment. As well, I perform a series of tests based on project/clients’ requirements. I provide documentation and reporting of all coating activities.

How much of your time is spent ‘hands on’ and how much with other activities?

This depends on the volume of work and requirements, so I work where I am needed.

Most challenging part of the job

What is the most challenging part of your job – technical side, people, or weather?

The most challenging part of the job is when dealing with people who try to compromise the project’s specification or quality of the job and when the atmospheric/weather conditions remain unfavourable.

How do you deal with challenging circumstances?

I see challenges as a way of learning.

How do you explain technical issues to non-technical people?

I try to explain better in a layman’s term while putting more emphasis on the requirements.

How physical is your job and how do you stay fit?

The job requires physical strength. I exercise regularly. Eat fruit and drink a lot of water.

Future engineers

Why would you recommend this type of role to someone who has studied chemical engineering?

Coating engineering is a branch of chemical engineering. I would advise any chemical engineering graduate who aspires to be a quality engineer/inspector to take this career path; which is also a quality control role. There is a lot to learn in the field.

Apart from a strong technical background, what are the three most important skills to have?

The three most important skills of a coating inspector include:

attention to detail,

effective communication

integrity.

Further Reading

Arturo González Ballast Water Treatment Service Engineer at Alfa Laval

Responses