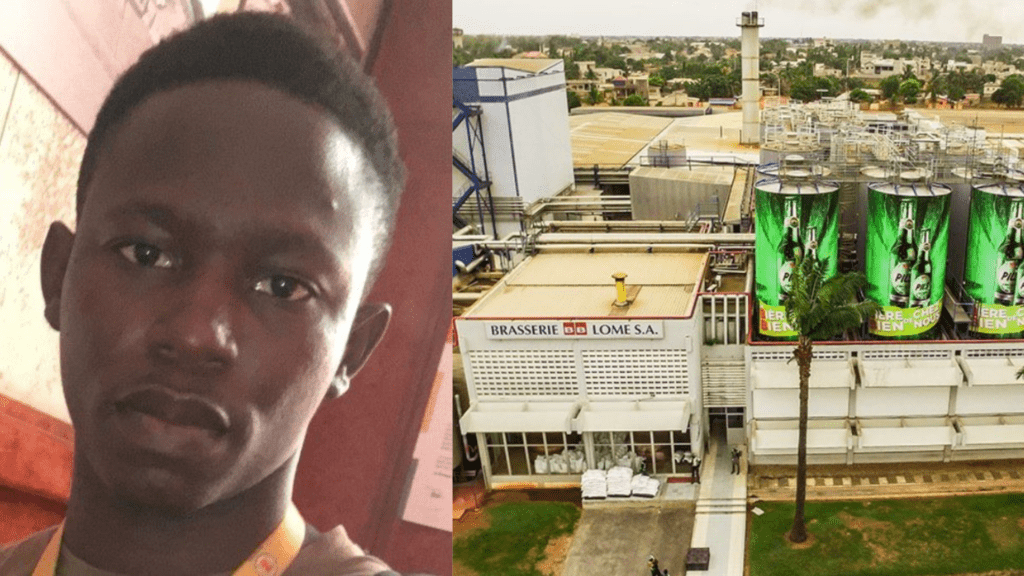

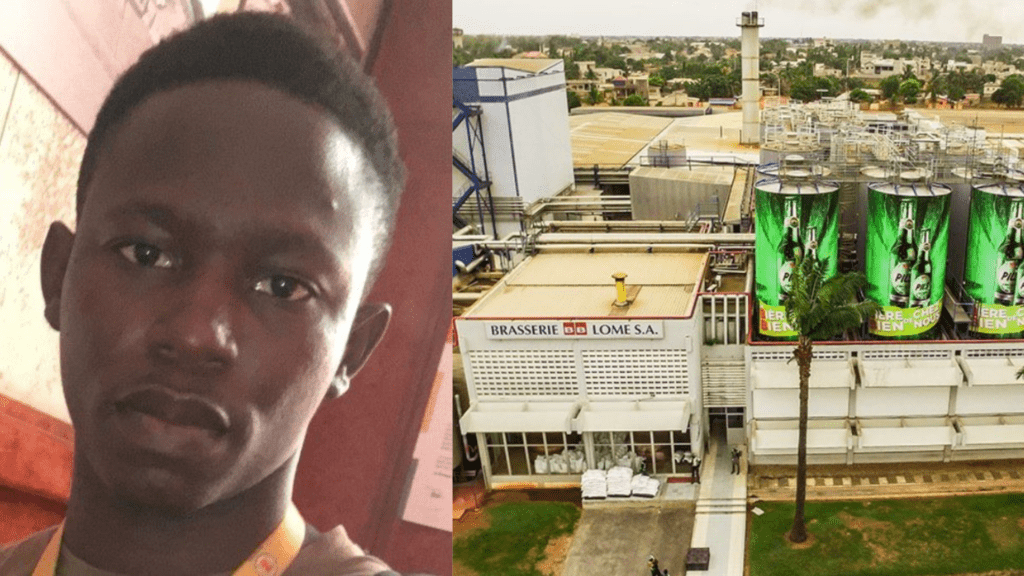

Successful working life of an Automation Engineer

Marc Yvan Wabo Fotso has a master’s degree in industrial engineering and is from Cameroon.

He has experience working in a thermal power plant where he set up a solution for supervising the wastewater treatment. Marc Yvan has also worked on human machine interface – HMI migration projects on behalf of Boissons du Cameroun (Les Brasseries du Cameroun, Socaver, Semc) Cameroon Mineral Water Company).

He is currently an Automation Engineer for the food and beverage manufacturing company, Brasserie BB Lomé S.A., and is working in Togo.

Marc Yvan Wabo Fotso Automation Engineer from Cameroon

Background and path to field engineering

Background and path to field engineering

Could you give a brief description of your background and why you decided to study and gained a Masters’ degree in Industrial Engineering?

After I completed high school, I was interested in being either a surgical doctor or taking an active part in the changing world as an engineer.

Then after I passed the entrance exam for the Institut Universitaire Catholique Saint Jerome De Douala, I decided to become a Mechatronic Engineer. My engineering training covered a lot including:

Programming of Siemens PLC

TOEFL -Test of English as a Foreign Language

and

TOEIC -Certification Test of English for International Communication

Leadership and management

Different types of electrical design.

Are other people in your family engineers?

No, I am the first Engineer in my family.

Moving countries as an Automation Engineer

You have moved from Cameroon to Togo to work. Have you noticed any differences in working styles?

Of course, there are many differences in working styles compared to my home country.

As part of the technical direction, the main function of our team is to assure availability of equipment by fixing issues quickly. However, here in Togo, there is a lot of procedural work to be done before the implementation of corrective action. So, it can take a lot of time even for a simple issue.

Languages

How many languages do you speak?

I speak two languages: French and English.

Do you think speaking more than one language helps your communication skills in general?

I think that yes, it’s very helpful.

For example, we are currently involved in a commissioning project of a new Krones packaging line. As an automation engineer, I need to exchange information with other engineers from different countries (France, Kenya, Germany, Italy …) in French or in English.

Typical day as an Automation Engineer

What’s your typical day like?

I start my working day by taking information from my colleague about what was done when I was not on site.

After that I check over all the equipment in our four packaging lines. I check the cleaning in place station and filtration equipment to check if there are any issues not noticed by the operators.

If there are any problems, I plan procedural and technical actions to fix it.

If not, there are many SCADA projects in our department, so I pick one and start to design it.

How much of your time is spent on site with the equipment? How much time is spent in doing other things like admin and training?

A huge part of my time is spent on developing new automation applications. Then I can spend five hours on training and designing and the last three hours solving issues on the equipment.

Equipment used in work as an Automation Engineer

What are the types of equipment you maintain in your current job?

It’s mainly automation and instrumentation equipment, for example:

Programmable logic controller,

sensor,

flow meter,

drive,

electrical equipment,

network equipment.

Another part of my job is to check if the procedures are being done correctly on different packaging units like fillers and labellers.

What other types of equipment do you have experience with?

Clean in place equipment

Brewing automation equipment

Filler

Bottle washer

Palletiser

Checkmat

Control system of conveyor

Filtration system

Protective clothing

What sort of safety or protective clothing do you have to wear?

As an electrical and automation engineer, I wear the usual individual protection equipment like safety shoes, facial protection mask, gloves etc.

Most challenging part of the job

What do you find most challenging when you are working?

The most challenging side of my work is to study and understand the different programming architectures of different machine OEMs and to be able to modify and add different desired functionality without changing the program structure.

What has been your most challenging task so far?

My most challenging task so far was the upgrade of a Sidel palletiser system by integrating a new palletisation architecture. During two days of intense work, I understood the programming structure of the program and designed the new database and configuration for the new palletisation architecture. This change increased financial benefits of our industry during transportation of product.

Have you ever arrived on site and found that it was much easier than you expected? For example, did you ever need to simply switch on a machine?

Yes, it is usually the main problem with equipment, which is not correctly understood by the operator.

Health and Safety

The equipment you install is for beverage production.

Are there particular health and safety rules you need to follow in terms of hygiene (when on site)?

Like everywhere in the food industry, there are many hygiene rules for people and processes.

All people in the production area must remove all microbiological agents by washing hands and shoes with a particular solution.

There are a variety of products which are packaged on the same packaging line. So, to avoid product contamination during packaging, before we change from one product to another one, we go through a particular cleaning process with a hot acid solution and many rinsing steps.

New field engineers

What advice would you give to someone who has just started their first job as a field engineer? Or is considering moving into this field?

My advice is to always look for a challenging issue or situation to increase your knowledge and then to gain the reputation of being an incredible problem solver.

Apart from a strong technical background, what are the three most important skills to have?

Communication: to be able to communicate in more than one language and especially in English and German.

Interpersonal: to have strong interpersonal skills to keep the work environment positive.

To be humble and open to studying new skills.

Why would you recommend this profession?

For me, this profession is really challenging and can give an engineer an opportunity to work anywhere in the world and then to meet different cultures and people.

Further reading on automation and production engineers

Oluwaseun Adu Automation, Control and Instrumentation Field Service Engineer

A US Navy veteran who installs and services baking production line equipment for Kaak North America

A food and beverage production line equipment Field Service Engineer – meet Philip Asamoah Boamah

Responses