Life of a Coiled Tubing Operator at Halliburton

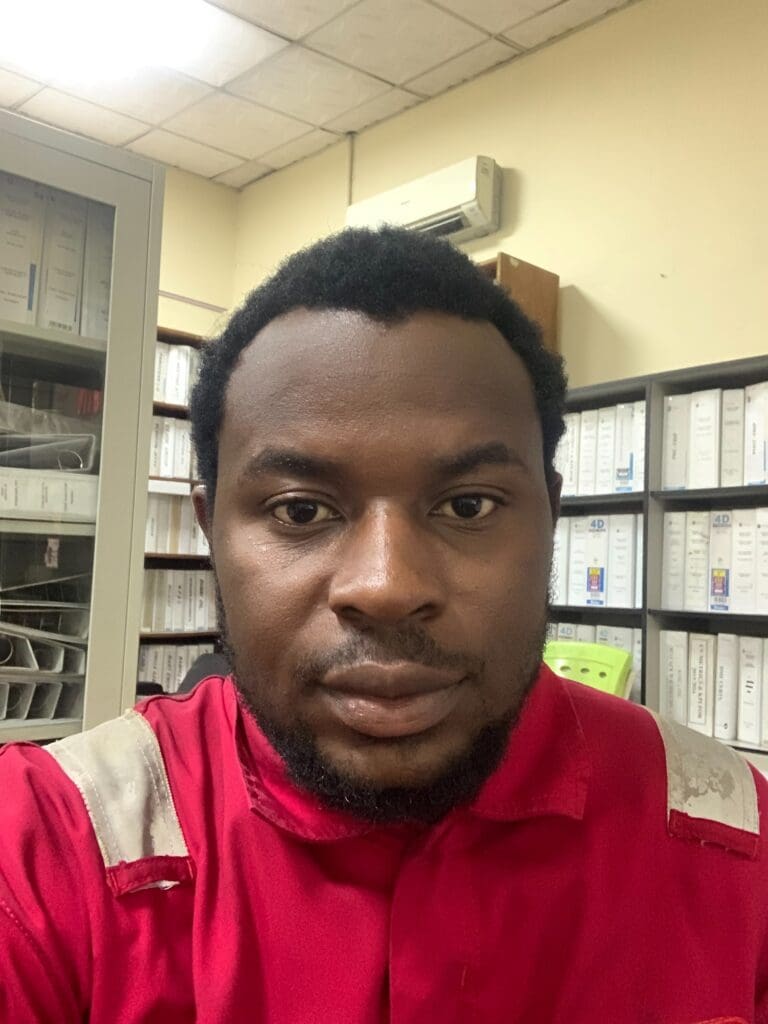

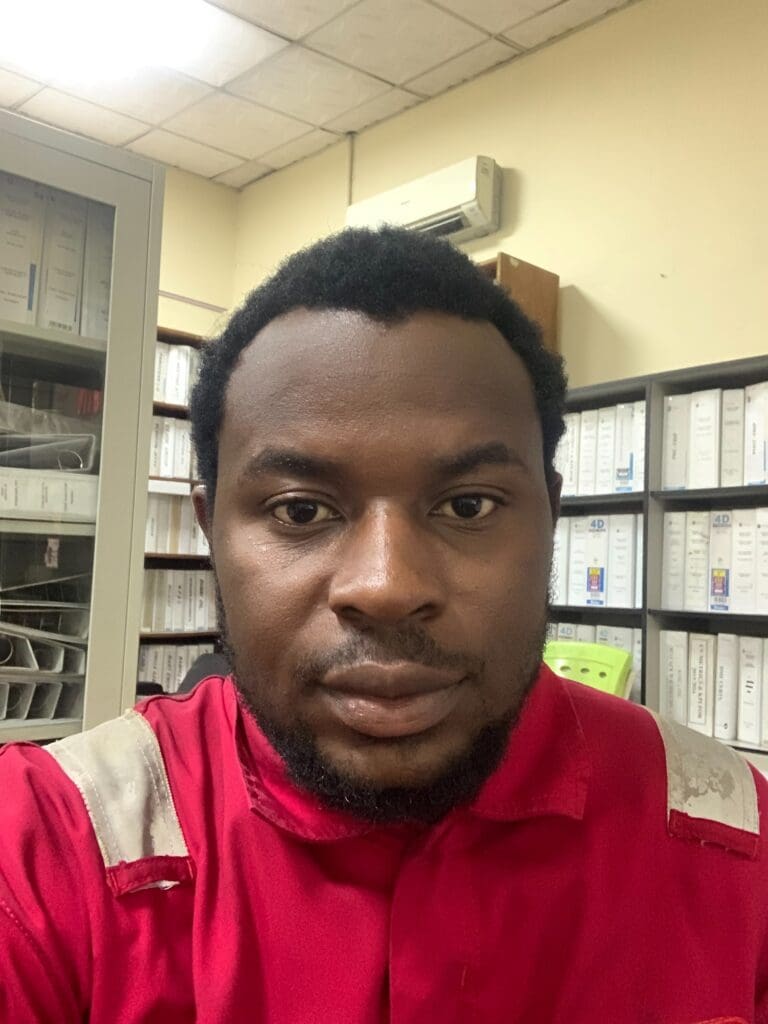

Kevin Chimezie Akparanta has a background in electrical and electronic engineering. He works for Halliburton as a Coiled Tubing Operator. Kevin is based in Nigeria but spends a lot of his time offshore.

Kevin Chimezie Akparanta a Coiled Tubing Operator at Halliburton in Nigeria

Background and path to engineering

Could you give a brief description of your background and what led you to study and work in engineering?

I was always that child who wanted to fix things and make things work. The engineering profession came to me naturally. I was always willing to get my hands dirty, solve puzzles and make things work better.

My mother has always seen the engineer in me, so studying engineering was a natural choice.

Were you interested in science and engineering when you were a child?

Yes, definitely. In particular, I was very much interested in mathematics and physics.

Was there anyone in your family who guided you towards engineering?

Yes, my father is an engineer. I grew up watching him work on electric motors and filling machines.

Has there been a particular person who has inspired you at university or at work?

My supervisor at work has always made me want to work more as an engineer and to get results and exceed targets. Also, my friend has always been a boost to me back in school.

Why did you choose electrical and electronic engineering?

I find electrical engineering easy to understand and its topics are things I like. Also growing up the challenges of electricity in my locality made me interested in being an electrical engineer.

Studying and working as a Coiled Tubing Operator

You are learning Python at the moment. How do you balance working and studying?

It is very challenging. Currently my Python classes are on hold because of the tight schedules offshore and current energy challenges in the oil sector.

Do you think that studying is important for engineers as they progress through their careers?

Studying is very vital for continuous improvement and relevance in our changing society.

Typical day as a Coiled Tubing Operator

What’s your typical day like?

During the day it is either work at the base (equipment maintenance) or offshore (well intervention).

At night I:

go through the internet (mostly LinkedIn);

practice my online courses (Python and SQL but not always);

check out field engineer roles outside Africa;

search for international master programs and scholarships.

Coiled tubing operation

Could you explain what coiled tubing operation is?

Coiled tubing operation is a form of well intervention in the oil and gas industry. It is used for performing routine well maintenance for land, swamp locations, and offshore.

Coiled tubing operation comprises of drilling, stimulation, well control, completions, tools and testing, sand control, logging, and cementing operation.

The coiled tubing alone refers to a very long metal pipe of different outside diameters. Whereas the operation comprises of several other pieces of equipment that make up the complete coiled tubing unit, which drives this coiled tubing pipe under pressure to the required destination in the well to perform any required maintenance as requested.

Work patterns while working as a Coiled Tubing Operator

Do you work on a shift or rotational basis?

I work on shift depending on the request by the client. This is not always the case. For example, I am currently on a 12-hour operation offshore which does not require any shift work.

Do you have to be on call at night or weekends?

I work most weekends at the base onshore.

When I am offshore there is no weekend: I work every day until I go on time off or the crew change.

Most challenging part of the job

What do you find most challenging when you are working – technical side, other people, or logistics?

Technical side

Jobs in the oil and gas sector come with a design of service or a work instruction/ flow diagram that guide how the operation is performed. However, most of these designs depend on the well behaviour.

For example, you are expected to run in hole with coiled tubing to 4000ft deep into the well and expect not to get any restrictions but observe a restriction at 1400ft which was not expected. That means that the job scope has changed, and you need to look at all the parameters while observing restrictions at that depth.

At this point, the job design will be reviewed, and job scope changed to get to the desired destination.

The job is dynamic depending on the well to be worked on and its behaviour; no two jobs are the same. It might be the same scope but a different location and different weather conditions.

People

I don’t find many challenges working with other people. Though some clients might not be friendly, but I tend to manage it.

Logistics

The times we have to overstay on offshore platforms is due to either poor planning or sometimes weather conditions. So, I tend to miss several occasions with family and friends. For example, I have just missed the holiday (Christmas and New Year) because I am on a remote offshore platform.

Most challenging job as a Coiled Tubing Operator

What has been your most challenging job so far?

I can’t pinpoint any specific job, as all jobs have their own challenges. Some places are very hot, some clients very challenging, some locations have bad meals, but I try to overcome those challenges.

Is your role ever uncomfortable because of heat, cramped spaces, bad lighting etc? What are your tips for managing this?

During the coiled tubing operation, as an operator I am positioned at a spot for hours operating the equipment. My eyes are glued to the data acquisition screen and the coiled tubing pipe. In addition, when working the night shift, you have to contend with lighting and constantly looking at a cycling drum of pipe.

The best way I try to counter cramps and eyestrain is by:

making sure there is proper lighting;

not sitting constantly;

chewing gum sometimes.

Advice for new field engineers

What advice would you give to new engineers:

In their first week?

The job is not a walk in the park; it can be energy draining, tiring and dirty sometimes.

In their first month?

The job requires patience and dedication because it is quite confusing in the first month.

In their first year?

The job makes a lot of sense by now. What will make you outstanding is constantly reading and improving yourself.

Apart from a strong technical background, what are the three most important skills to have?

Management skills, communication skills, and data analysis skills.

Making a winner

What makes the type of engineer who is tomorrow’s senior engineer or team leader?

Training, determination and taking on responsibilities and seeing yourself at a higher role and acting as if you are already there.

How important are people and communication skills?

The engineering profession is nothing without people, networking, and communication. You need people to learn from and you cannot learn without communication.

How key is it to have a mentor and a good team supporting each individual engineer?

Mentorship is key for shaping any great engineer. Having a mentor in the oil and gas industry has helped me grow and learn in the industry faster than I thought.

Responses