How Field Engineers need skills that cross all career boundaries

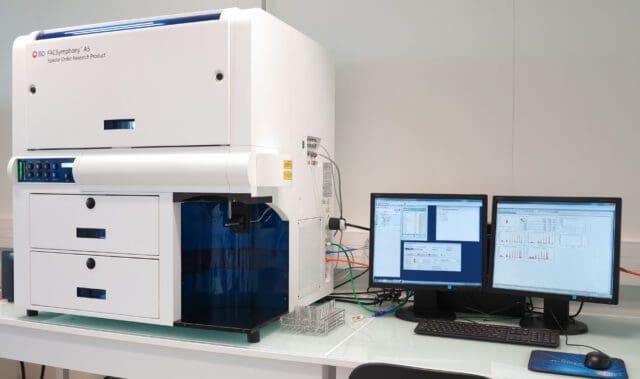

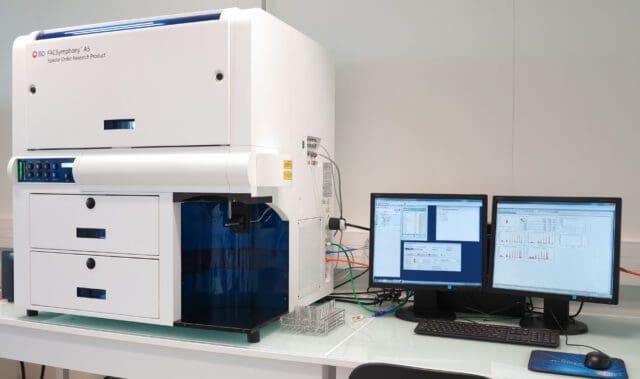

Frank Pemberton has over twenty years in medical equipment field service and management after fifteen years in the semiconductor industry. Frank is now a Field Service Engineer for BD Biosciences , part of Beckton Dickinson supporting cell analysers and cell sorters. He is based in San Antonio, Texas. In this article he looks at how field engineers need skills that cross all career boundaries.

Background and path to engineering

You started your working life in the Air Force. Was this an ambition from childhood?

I actually did not know what I wanted to do in the Air Force. I was trying to get into voice processing but didn’t qualify to learn an Eastern Bloc language. Electronics was a new hot commodity, although I had never studied electronics, my scores were high enough to get me into electronics college which lasted 8 months. This is one of the Air Force’s longest courses.

What experience did you take from the Air Force into civilian life?

I highly recommend the military to anyone and everyone. That is because it instils discipline, professionalism, timeliness, and taught me life-long skills. Because of what the Air Force taught me, I have never had to look back and rethink my career or destination.

Have you always been interested in technology and the way things work?

Yes, as a young man, I remember wiring in a momentary wiper switch into my 71 Chevy Nova so that I could do single sweeps of the wipers not full on. This was before it was even a thing to do.

Semiconductor to medical – transferring field engineer skills

After the Air Force Frank worked for various Semiconductor equipment companies, including Eaton Corporation’s Ion implantation systems (now Axcelis), Thermawave (now part of KLA Tencor), and Applied Materials, before moving into the medical industry.

You have moved from the semiconductor to the medical industry? How difficult was the transition?

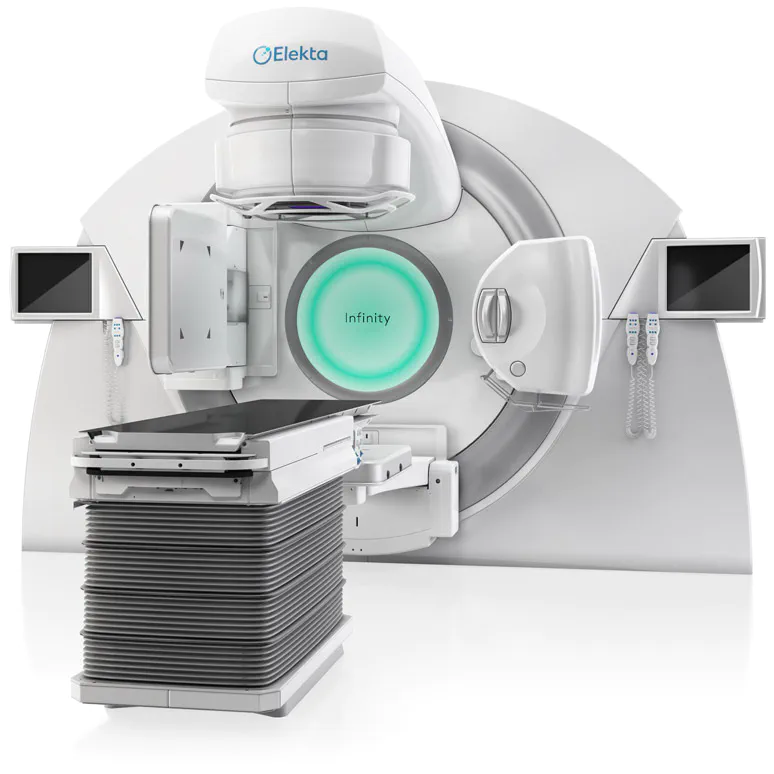

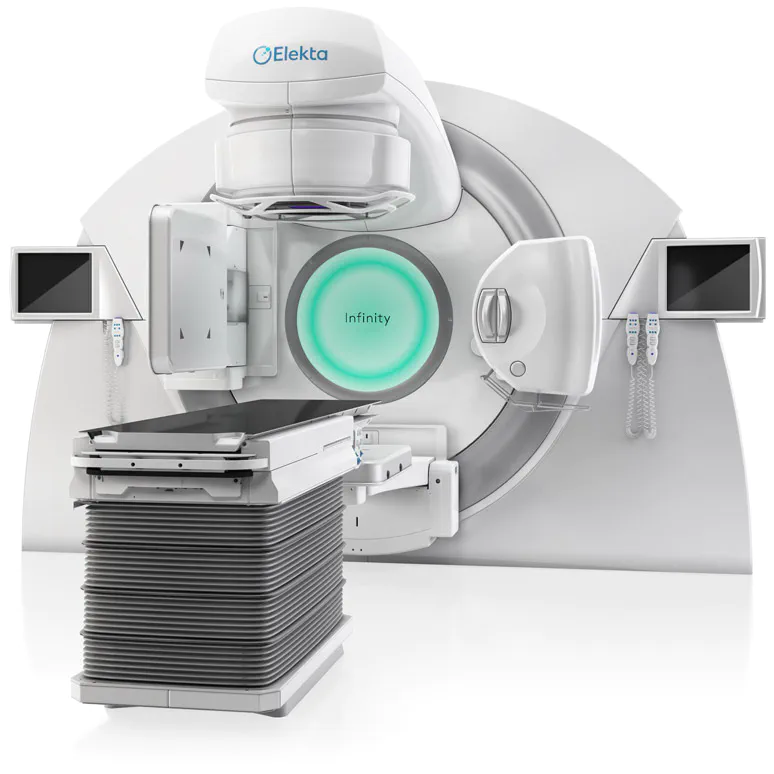

The transition to medical from semiconductors after twenty years in semiconductor was an easy step. I did it out of necessity, as my wife had been offered her first post-doctoral job at the University of Texas at El Paso (UTEP). At the time, I was teaching electronics in San Jose monthly, living in Austin and commuting to see her. So, I checked the local papers and found Elekta was looking for a FSE in El Paso. What were the odds? I made that job my own and stayed with them for over seven years, eventually becoming one of their field service managers.

Transferable skills

Which skills are interchangeable?

Field service engineering requires skills that cross all career boundaries:

Timeliness,

Attention to detail,

Customer satisfaction,

Aptitude to learn new instruments and systems,

Ability to work long and flexible hours.

The list goes on and on.

Once an engineer is a good field service engineer, do you think it is possible to work in any industry and with any technology (with some training)?

Exactly my point: once you learn the base skills of a field service engineer, these skills pass over to any other industry. So, learn the basics, excel at them, keep an open mind and I always say:

“Learn at least one new thing every day.”

It keeps you fresh, motivated, and learning all the time.

Equipment

Can you describe the type of equipment you support?

The instruments I work on do one of two things: cell analysis or cell sorting.

In today’s post-covid world there is much work on DNA, cell sequencing, cell analysis and further biological work in the cell structures and of course on-going cancer treatment.

Our instruments use lasers to deflect light and produce signals from dye-stained samples to fill certain populations that correspond to known blood diseases or abnormalities. These results help researchers, pathologists, lab clinicians and other doctors to analyse and determine characteristics of blood.

Typical week

What’s your typical week like?

Becton Dickinson and other companies use Salesforce or ServiceMax to dispatch jobs to us in our locations.

They come in two priorities:

clinical we must respond within 24 hours,

or research within 48 hours.

We are empowered to do our job and go to the customers that need our services first. Our job is very dynamic, changing daily and weekly. We also get new training, do a lot of computer-based training, and handle our own expenses and administration. We work from home and our manager typically lives in another state, mine lives in Arkansas.

How much of your time is spent ‘hands on’ with customers and how much on administration, training, and other aspects of your role?

Our field work is 80% of our weeks, the other 20% is admin and inventory management and/or training (some of which is computer-based training – CBT).

Which other people in the workplace give you support?

Our headquarters is in San Jose, California. Our expenses are processed in a finance centre here in San Antonio. We get HR support, management support and other support all online, or using Microsoft Teams.

Volunteering

What is your aim for volunteering?

Habitat for Humanity, will be my organisation to support after retirement. I still have three boys at home and so have not allocated time to volunteer work YET.

Habitat for Humanity is a non-profit organisation that helps people in your community and around the world build or improve a place they can call home.

Most challenging part of the job

What is the most challenging part of your job – technical side, logistics or customers?

Technical is the hardest. Our equipment and the technology is changing so fast, that you must work hard and keep learning new instruments to keep up. We have a great support network in case you get stuck on a problem and cannot resolve it easily. We escalate up to senior engineers, local specialist, then global specialist to come up with a solution. BD has a wonderful escalation process that ensures we do resolve any instrument issue in a timely manner.

What has been your most challenging job to date?

My most challenging job was at Elekta, maintaining the LINACs, cancer treating linear accelerators. Knowing there was a room full of patients waiting to be treated sometimes would cause pressure. My way of coping was to block them out, focus on the job in hand, then afterwards walk to the lobby proudly so that they could see field service was there and they would be treated soon.

How do you explain technical issues to non-technical people?

Like any profession, you learn to speak in layperson’s terms, but honestly, most of my customers have PhDs, so I don’t have to do that.

Making a future star

Apart from a strong technical background, what are the three most important skills for a field service engineer to have?

Listen to the customer, always.

Be professional.

Always communicate the time you plan to arrive and keep the customer “in the know” at all times if you think that the arrival time is likely to change.

What sort of personality traits are ideal for a field service engineer to be successful?

Firstly, having a huge capacity to learn and a thirst for knowledge.

Secondly, a friendly yet focused demeanour is best. You must have some fun but be serious when you need to. In other words, be friendly, but stay focused.

Thirdly, most engineers are introverts, but a few, like me are extroverts and it’s fun to get to know your customers and to become part “of their team.”

Is there anyone who should not consider working in field engineering?

Field service is not digital, it’s not a cut and dried 8am-5pm job. It takes flexibility and a huge desire to learn and to keep learning, and to be happy working in a very dynamic environment.

Leading and managing a team

How important is it for the manager or team leader to remain hands-on?

I have had good managers from both backgrounds, those from the field that rose up, and those that just knew how to manage. It’s not a given that someone who has been a FSE will make a good manager.

What is your advice for motivating a team of service engineers?

The customer or patient is at the end of everything we do. Customer satisfaction will lead to repeat sales, repeat business, and huge trust. So, keep the customer happy, by keeping the FSE happy and it will all come back to the company providing the services.

Within a team, how do you improve confidence in those who need it?

Technical competence comes from first being shown a procedure, next having someone help you do the procedure, then doing the procedure on your own. By utilising these steps, you will become confident in your own abilities and others will notice.

How do you support someone in your team when things have gone wrong because of a mistake?

You have to be honest, show them what they did wrong, show them why it was wrong. After than you teach them the right way. Do not make them feel bad or use negative feedback, use positive feedback to correct the mistake and move on.

Further reading about field engineer skills

Meet Michelly Rodrigues Field Services Engineer with GE HealthCare from Brazil

Paul Camidge Senior Regional Service Manager Northern Europe at Cepheid

Responses