Toolkit for starting as a Field Engineer – 6

Starting as a Field Engineer – what’s in your toolkit – part 6

If you are a new field engineer either starting your first job, or switching into field engineering from another role or industry, you may be wondering:

What tools should I include in my toolkit?

Is there anything really useful that I may not have considered?

How can I carry everything?

Following our first five articles,

Starting as a Field Engineer – what’s in your toolkit

We have had more advice from experienced and veteran Field Engineers for part 6.

This time the advice includes a mesh bag and a special piece of carboard.

A Semiconductor Field Service Engineer based in Italy

Federico Castoldi is a Field Service Engineer supporting semiconductor manufacturing equipment for Tokyo Electron (TEL). He is based in Lombardy in Italy.

Before joining TEL Federico had over thirteen years of experience in the telecommunications industry.

Tokyo Electron is one of the top five Semiconductor equipment manufacturers and suppliers in the world with its Headquarters in Tokyo, Japan. TEL focuses on Coater/Developers, Etch systems, Surface Preparation systems, Deposition, and Test systems. It is also a major supplier of equipment to manufacture Flat Panel Displays (FPD).

The tools of a field engineer

What is in your tool kit which is non-standard but really useful?

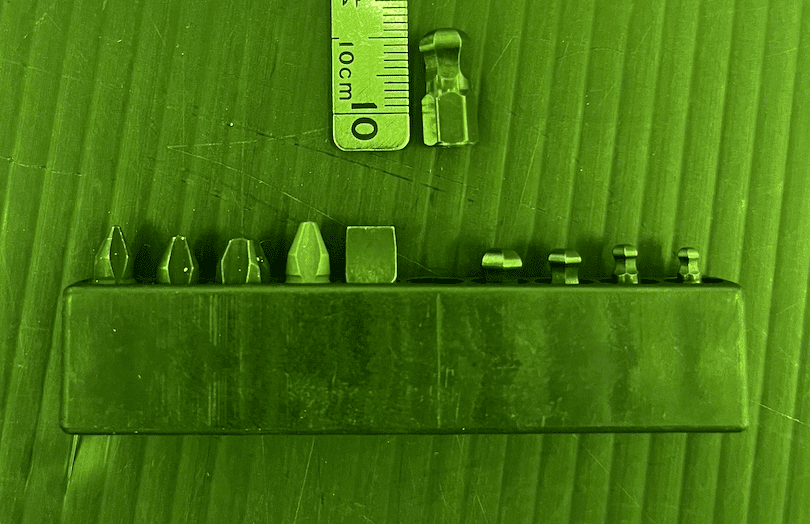

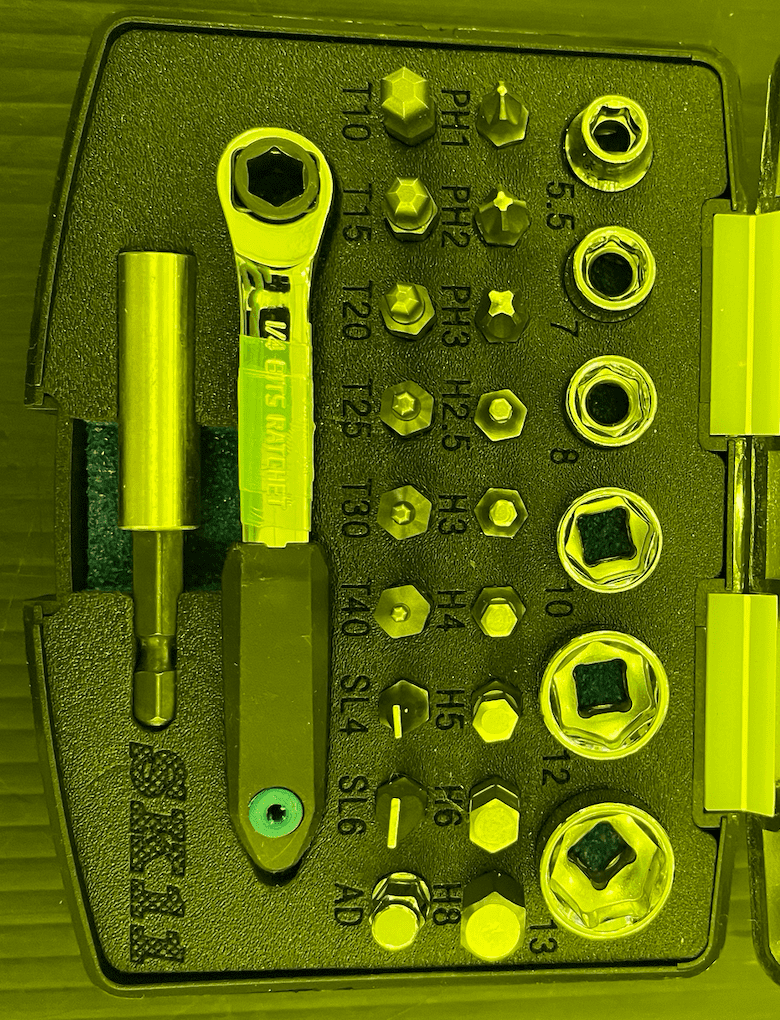

My best non-standard, but very useful tool is a fully customized bit set. In this set, the hex-ball tips have a very low cut, handmade in a factory by a friend of mine.

Which tools could you not work without as a field engineer?

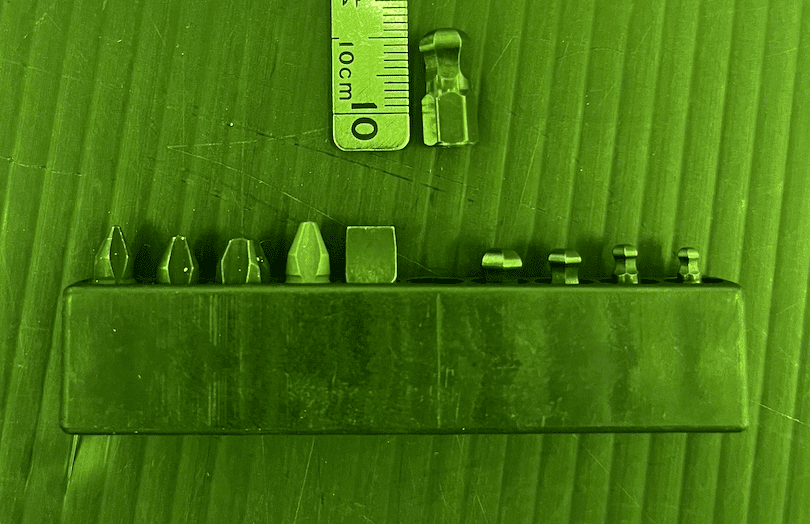

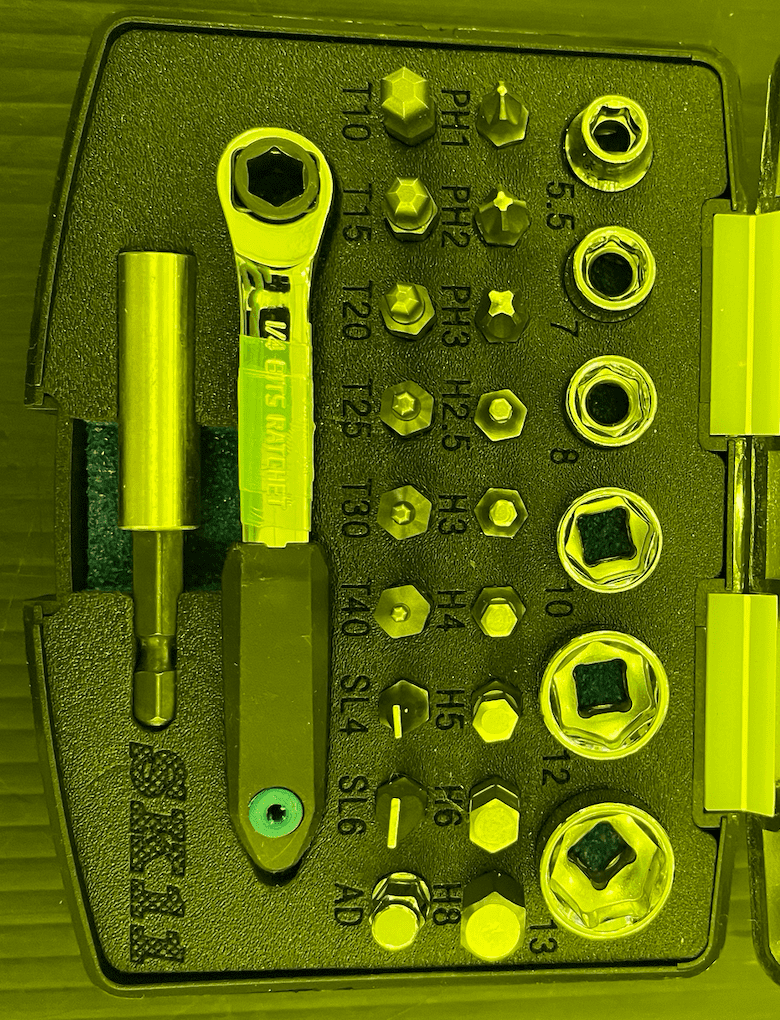

I could not work without my Sk11 ratchet set, with ESCO hex-ball bits and related sockets.

The other tool which is vital is my Japanese wrench set. They’re small, hard, light, and wide; with them, you can fix almost every fitting if you are working on a Japanese semiconductor tool!

Is there a tool you have which would not be generally recognisable?

I have an ESD (electrostatic discharge) pouch which I use in clean rooms to separate the tools. These bags, made of PVC, are very important for us.

Carrying tools as a field engineer

What’s the best bag, box, or case you have ever used?

The best toolbox to be honest for me is not the current one I’m using. I bought this one a few months ago in a common chain here in Italy (and immediately customized internally, removing everything and adding a new heavy-duty bottom layer).

In the future, I would like to buy a hard case from Trusco or Pelican (even though Pelican is usually a little heavier).

I’ve also found an alternative from Amazon Japan, which is probably lighter – the GT-c Astage ABS strong case. Although, maybe with shipping and taxes, it won’t end up being as cheap.

Anyway, having said all that, I’m happy with my toolbox.

Advice

What is the best piece of field engineer advice you have ever been given?

The best piece of advice I’ve ever had is in four parts.

Be:

Patient

Focused

Willing to learn

Always follow the safety procedures if you want to come home safely.

The other thing to do is to ask for help and support if you need it. I’ve been working in the semiconductor industry since 2019. I’ve found that in this field, that every day you can encounter issues you’ve never seen before. In these cases, the help of others is vital and will help you solve the technical problem. It will also make your customer happy (especially if the customer is always behind you, watching what you’re doing and asking you if you have finished every 30-40 minutes..).

Field Services Engineer in Canada

Alvaro R Hernandez Mendez is from Mexico and now lives in Canada.

He studied Mechanical Engineering and has worked for Tetra Pak for over 25 years.

Although he lives in Canada, he works for 90% of his time in the United States. At the moment he is mainly covering Michigan state with three major customers. In Michigan he’s in the village of Paw Paw for most of his time as he supports a customer who has 6 lines.

Alvaro doesn’t just travel for work; he has also taken part in a triatholon/triatlón in Cozumel Mexico. He was on a bike.

He travelled even more before and has worked in 23 countries and lived in 4.

The Equipment

What sort of equipment do you work on?

My experience is most of the filling platforms:

A3 speed, A3 Flex, A3Compact,

TBA8, TBA21, TBA22,

all Distribution equipment.

I do maintenance -Tetra Pak Preventive Maintenance – TPMS, PLC programming, installations, start-ups, commissioning, mechanic validation, trouble shooting, production cover, etc.

The tools of a field engineer

What is in your toolkit which is non-standard but really useful?

I always have a piece of cardboard with me. It doesn’t look like much but is really useful.

I invented this and it is now called the “Mexican template”. My colleagues gave it that name. I started to use it as the creases on it fit perfectly into the machine to align all the carriers!!!

Which tool could you not work without?

In the industry I work in there are two must haves in my toolbox:

Wrenches – 13&10 mm

Allen Key Metric. Maybe in a few forms (socket, crown, open, etc).

Carrying tools as a field engineer

What sort of toolbox do you prefer to use?

At the moment I use the NASCAR toolbox. The stickers decorating it are my own.

Responses