Toolkit for starting as a Field Engineer – 4

Starting as a Field Engineer – what’s in your toolkit – part 4

If you are a new field engineer either starting your first job, or switching into field engineering from another role or industry, you may be wondering:

What should I include in my toolkit?

Is there anything really useful that I may not have considered?

How can I carry everything?

Following our first three articles,

Starting as a Field Engineer – what’s in your toolkit

We have had more advice from experienced and veteran Field Engineers for part 4

This time the advice includes a blackboard erasable marker and a caliper.

Biomedical Field Service Engineer in Libya

Karim Algazzar works as a Field Service Engineer specialising in MRI and CT. At the moment, he works for Siemens Healthineers and is based in Libya

He studied Biomedical Engineering in the German Jordanian University. After that, he had the chance to do an internship in ECG signal detection enhancement with a company called MedPersonal GmbH in Frankfurt, Germany.

After completing the internship, he switched to radiology.

Radiology

What attracted you to radiology?

Radiology is a very interesting, demanding and challenging field.

That’s the reason I love it. I need to solve problems every single day as well as moving from one site to another meeting different people from different fields. I could say that every day is a different experience.

The tools

What is in your tool kit/bag which is nonstandard but really useful?

A leak detector is a very useful device during MRI installation or MRI quenching. It means we can detect leakage and diagnose the MRI without going through the trouble of disassembling parts or being invasive.

Which tool could you not work without?

I could not work without the magnet power supply which is the device we use to ramp up the magnet (or for starting the magnetic field).

What’s the best bag, box or case you have ever used?

The ideal for me is a non-magnetic tools bag which contains tools made of steel or titanium. I need these so I can use them when the magnetic field is ON.

Global Field Service Engineer based in the United States

Don Ingersoll is qualified in Electronic Engineering and Business Management and has worked as a hands-on engineer and leader for over twenty-five years. He is currently a Global Field Service Engineer for Shellback Semiconductor Technology.

The tools in the field engineer toolkit

What is your key piece of advice for anyone investing in tools?

One thing I would recommend after 30 years in the business is don’t skimp on tool quality.

Cheap Allen Key or Hex Key sets will strip the inside if heavy pressure is applied.

The same thing goes for wrenches and sockets.

While adjustable wrenches have their uses if there is any slip in the adjustment or jaws get a new one. If you need one that exceeds the jaws of a 6-inch wrench, get the correct open end box end.

Make sure your direction of pressure on an adjustable is not against the clamping side; it’s rounded edges just waiting to happen.

I bought my first set 30 years ago and I’m still using them. I’ve had to replace a few items because they fell 30 feet and bounced who knows where. However, I don’t think any of them have failed.

Finally get a quality flashlight (torch). I have a USB rechargeable Fenix that I’ve charged 5 or so times in 3 years. It comes with 6 levels of brightness ranging from your basic Maglite® to something approaching the face of the sun.

The tools themselves

What’s in your tool bag?

I’ve got high quality – screw drivers, Hex keys, ratcheting open/box end wrenches, 6-inch adjustable wrench, micro screwdrivers, micro wrenches, various size pliers, tubing cutters, Fluke 87 full rms meter with standard, sharp point and clip on leads. Fenix USB rechargeable flashlight, Magnetic end articulated flashlight, Wadsworth 152-piece super kit.

What can’t you do without?

I can’t manage without:

Fenix flashlight

Fluke87 and leads

Tone Hex keys

Nos 1 and 2 screwdrivers and wrenches

Wadsworth kit

A Leatherman.

Carrying tools

What’s the best bag, box or case you have ever used?

I’ve used Jensen multi pallet toolboxes.

Over the years I’ve also used a Pelican 1510 or the Apache 5800 (currently using with most of the foam removed so bags sit securely).

I’ve had the 5800 for two years and it has survived all the airlines can throw at it; it’s a much lower cost alternative to the Pelican 1510.

Advice

The best advice I can share is to plan the job and adjust what you carry. Preventative maintenance (PM) visits are different than overseas installations.

Field Service Lead for Immunodiagnostic Systems in Norway

Roberto Aghaei is based in Oslo and works for BD who are a global medical technology company.

He works on systems for:

Blood culture

Clinical microbiology

Mycobacteria testing

Identification

Susceptibility

The tools in the field engineer toolkit

What is in your tool kit/bag which is nonstandard but really useful?

It is not so strange, but a nonstandard tool I have in my tool bag is a calliper. It’s maybe not the strangest thing but not really a normal tool either.

Which tool could you not work without?

I could not work without my multimeter and my Torx socket set which also includes all the standard heads I need.

What’s the best bag, box or case you have ever used?

In my opinion, the best cases are without question Peli cases (Pelican cases). The quality is much better than any other bags/cases I have tried.

Advice

What is the best piece of field engineer advice you have ever been given?

The best advice I have been given is to prepare as much as possible for what you are going to do.

If you take on a challenge well prepared, you will not be stressed or surprised and you will most likely succeed on your first visit.

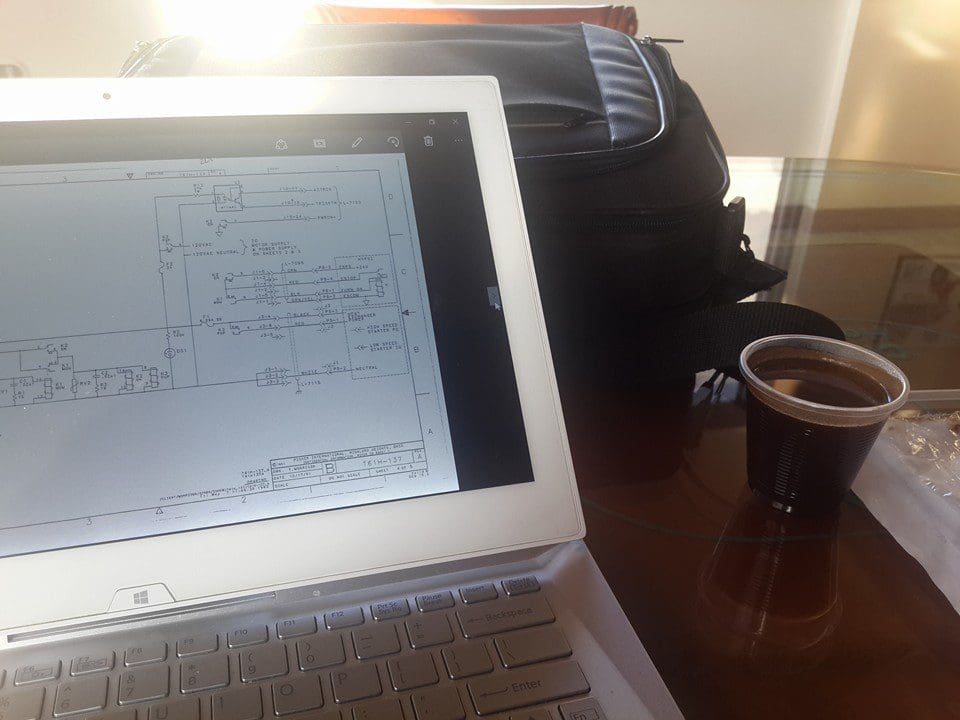

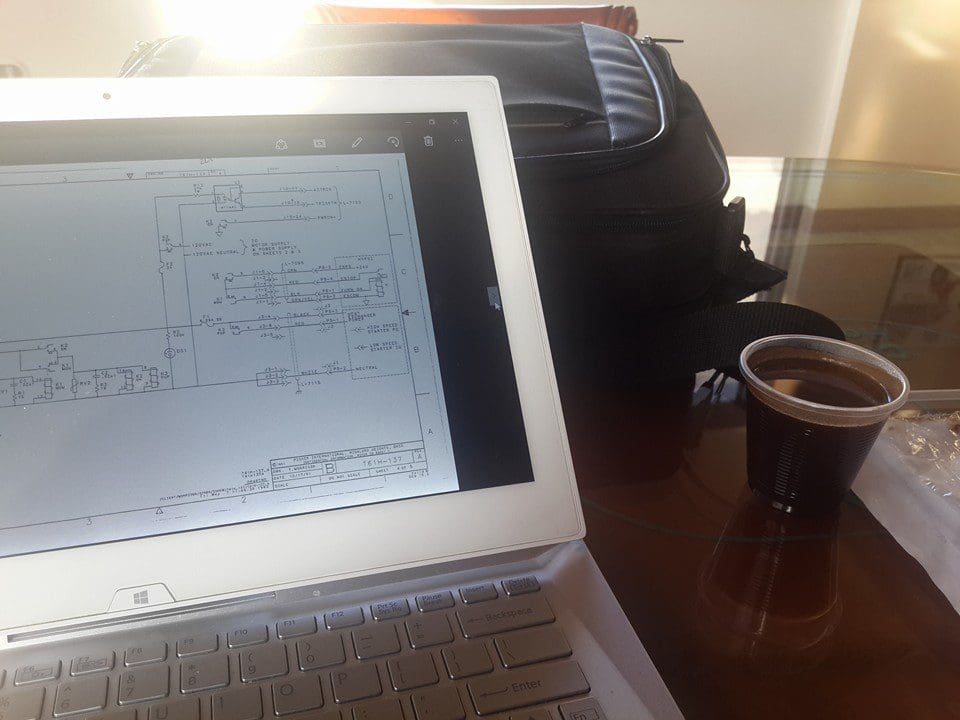

Biomedical Engineer in Chile

Jose Morillo is the third generation of his family to work as an engineer. He has worked in biomedical engineering for almost thirty years and covers a range of equipment over a wide geographical area. He has his own company – J.MORILLO. EQUIPOS MEDICOS.

The tools in the field engineer toolkit

You work on a lot of different types of equipment. How do you manage the tools you need?

Our service tool case MUST be an image of the quality we offer. As personal as the configuration of our cell phones.

I usually have the major set of tools (those most often used) in a case and others in my car. As well, I have “kits” for specific tasks such as a change of CT TUBE or replacement of a Cold Head in a Magnet.

All the tools in my case are often used. This allows it to be as light as possible.

What is in your tool kit/bag which is nonstandard but really useful?

The following tools are always with me:

A metallic and a plastic Vernier Caliper

Two colours of indelible ink marker and a blackboard erasable marker

a dentist stainless steel set

an alligator cables set

a non-magnetic 10mm ratchet

Which tool could you not work without?

In terms of tools, I could not work without a:

Phillips screwdrivers set.

In terms of instruments, I could not work without:

Service PC, calibrated multimeter, and a pocket DSO (Digital Storage Oscilloscope).

Carrying the field engineer toolkit

What’s the best bag, box or case you have ever used?

Eight years ago, I acquired a PLATT big-size tool case and love it. It replaced my old and original Xcelite Wood and leather suitcase.

Advice

What advice would you give to your younger self about being an engineer?

There are five key pieces of advice I would give.

Firstly, if you think you don´t need a tool, take it out of your suitcase and leave it in the car but NEVER leave it in the office.

Secondly, if you are troubleshooting complex equipment and locate a minor failure, fix it before continuing the troubleshooting. A lot of times they are related.

Thirdly, at the end of the service ALWAYS test the system and check no screws are missing or in excess.

Fourthly, be logical. Logic can save a lot of time troubleshooting a complex failure. Spend the initial time reading the errors log, talking with the operators, and over asking about the failure BEFORE beginning troubleshooting.

Lastly, clean the system before beginning to work.

Further Reading on field engineer toolkits

First part Starting as a Field Engineer – what’s in your toolkit

Second part Starting as a Field Engineer – what’s in your toolkit – part 2

Third part Starting as a Field Engineer – what’s in your toolkit – part 3

Responses