Expert insights on the digitalisation of medical field service

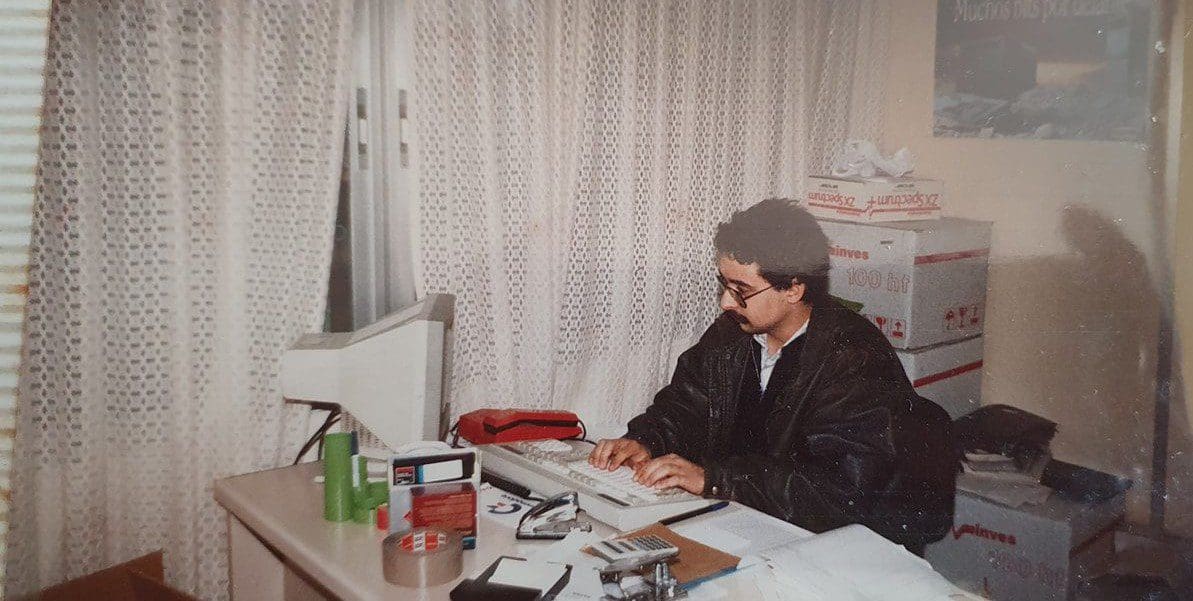

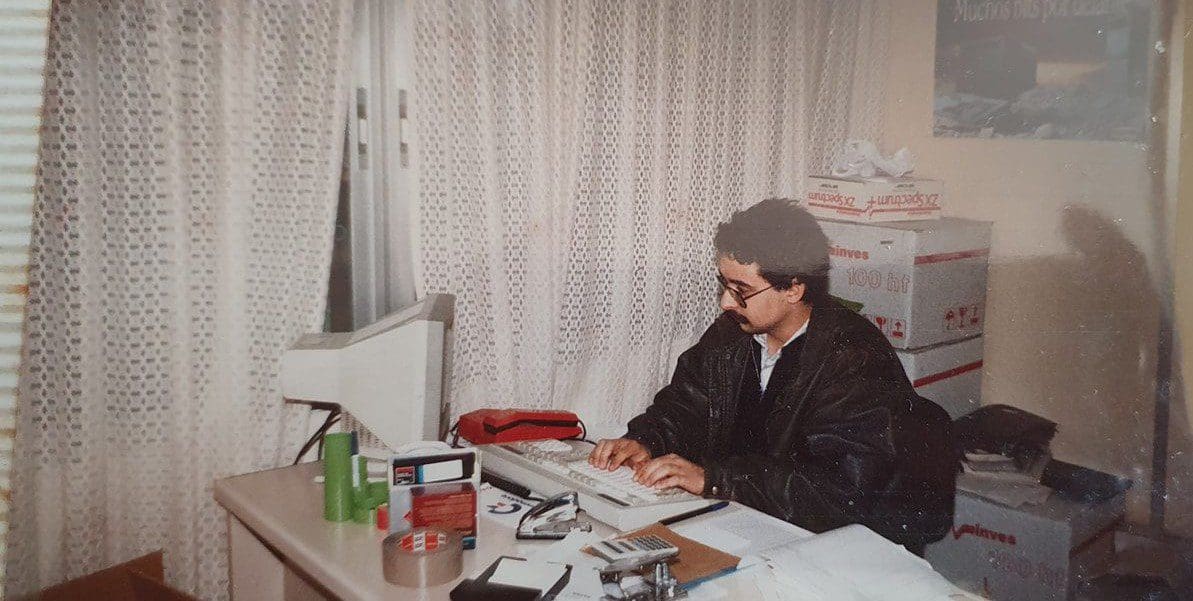

Luis Manuel Barreiro Blanco is the Digitalisation Team Head and Service Trainer at ZEISS Medical Technology. In this article he shares his experience and advice for training and discusses the future of digitalisation in the medical field service industry.

Luis Manuel Barreiro Blanco Digitalisation Team Head and Field Service Trainer at ZEISS Medical Technology

Background

Were you interested in how things worked as a child? Did you like taking apart toys for example?

Taking toys apart was one of my main reasons for arguing with my parents. Especially electronic toys that were scarce and expensive at this time. I also loved to read, and writers like Jules Verne who details a lot of engineering in his books, were a real inspiration.

Was there a family member who influenced your career choice?

Not really. No one in my family was involved with technology.

Why did you decide to study Electronics and then Information Technology and Computer Science?

When I started at high school and had to choose a path for my studies, it was also at the beginning of home computing. I remember a friend got his Sinclair ZX Spectrum and I fell in love with it. Then I realised that there was no IT related training available in my city or surroundings, so I chose Electronics as it was the closest one. Most of my IT training was then self-study, and I came back to college later in my life looking for more formal training.

Inspiration

Was there a particular person who inspired you at high school?

At high school, my physics teacher. He showed me problem solving, procedures and logical thinking that later became my most useful tool in my job.

Which famous scientist or engineer has inspired you?

If I must choose a single person, probably Newton.

IT to Prepress Equipment

After two years working in IT, you moved to Agfa Gevaert to work on prepress equipment.

Why did you take this opportunity?

It was not a conscious choice. After my military service, I found that my former company had closed the business in my area, and so I looked for new opportunities.

I then found this job in a sector I had never heard about. However, it was for a company I knew from the photography area, which was one of my main hobbies. So, I took the job and I moved into new and fantastic work. It was my first time working with optics, lasers, and fine mechanics, and I fell in love with those.

Which skills were transferable from your first role?

Luckily for me, the business in prepress was moving into computing and networking at that time. So, my IT background gave me an opportunity to help the service team to go into a completely different world from the analogue handcraft-style previous one.

Optoelectronics

What attracted you to moving into ophthalmic devices?

When digitalisation, mobile phones, and the Internet came into society, paper started to go down as the main support for information. Therefore, the graphic arts business weakened more and more. I had the choice then to move to a different area which was medical. However, with the same technologies such as optics, fine mechanics, and computing, that I love, and also in a top tech company like ZEISS.

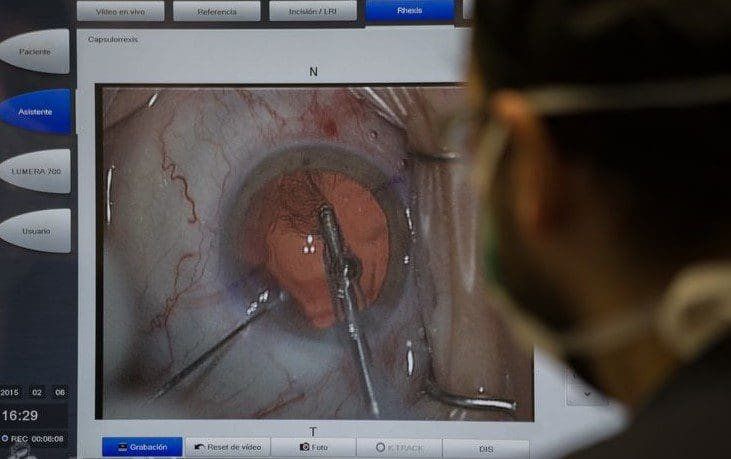

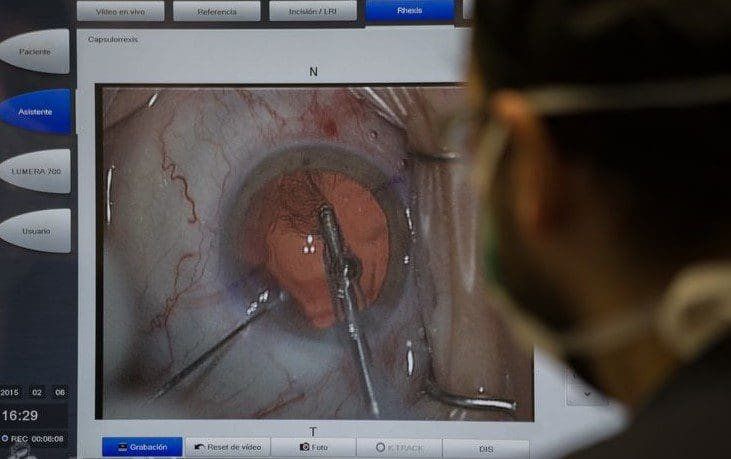

What are the types of equipment you have worked on during your time at ZEISS Medical Technology?

It has been a wide range of medical devices, but with the use of optics as a common characteristic. From surgical microscopes to therapy lasers, with a special personal interest in OCT Systems, (Optical Coherence Tomography) as they are a tough challenge to service and adjust, and I love big challenges.

Moving into training and medical digitalisation

Why did you decide to move into training?

Several years ago, I was chosen to be a trainer for a new soft skills programme. It was then that I realised that I love to teach and share knowledge. Then 2020 came, and during the pandemic lockdown, we started to train our FSEs in a virtual way. So, the trainer presents via videoconferencing, and a local co-trainer presents in the room to help them. I was the co-trainer for most of this time.

Later, and with ZEISS business in Spain and Portugal growing fast, more and more FSEs started to join the company. So, we realised that local training made sense. Apart from travelling, being trained in your own language helps to understand (and explain) the content better.

How would you advise other FSEs who are considering moving into training?

Training needs a set of soft skills from your side. You need to be able to break a problem into small parts and then write on a whiteboard. Also, you need to be confident in your knowledge and keep it updated with the latest information. Lastly, the most important thing, you need to be patient and able to explain a concept as many times as it takes for your trainee to understand.

What type of engineer makes an ideal trainer?

You need experience and expertise in the area/device you’re training and need to be into methodical step-by-step solving of problems. For sure, communication skills are also a must. And having a bucket of jokes on hand to wake up the classroom during the straight theory lectures.

Role as a Service Trainer alongside medical digitalisation

How much of your time is spent training over the course of a year?

Around half of my time is spent in training.

How many people have you trained to date?

Around twenty people during last year, but most of them attended several training sessions.

A FSE needs training in soft skills as well as technical skills; how important do you think this is and how do you balance the training?

Soft skills are an important part of the FSE background, as communication and contact with customers is part of their everyday work. We try to have all FSEs trained in our CONTact soft skills training during their initial time with the company. As well, we’re working on refresher sessions for the ones already trained.

In your opinion which soft skills are the most key?

Clear communication, empathy, presence, and out-of-the-box thinking.

Client facing skills

Whilst working as an FSE, how did you establish a relationship with a new client? How do you pass this skill onto other engineers?

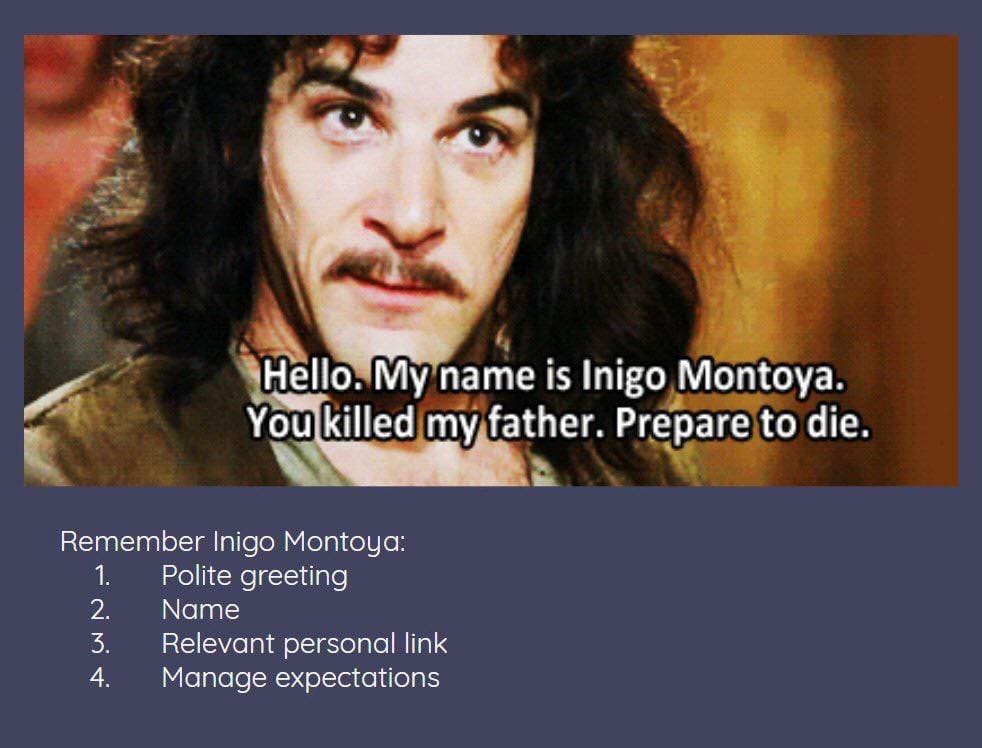

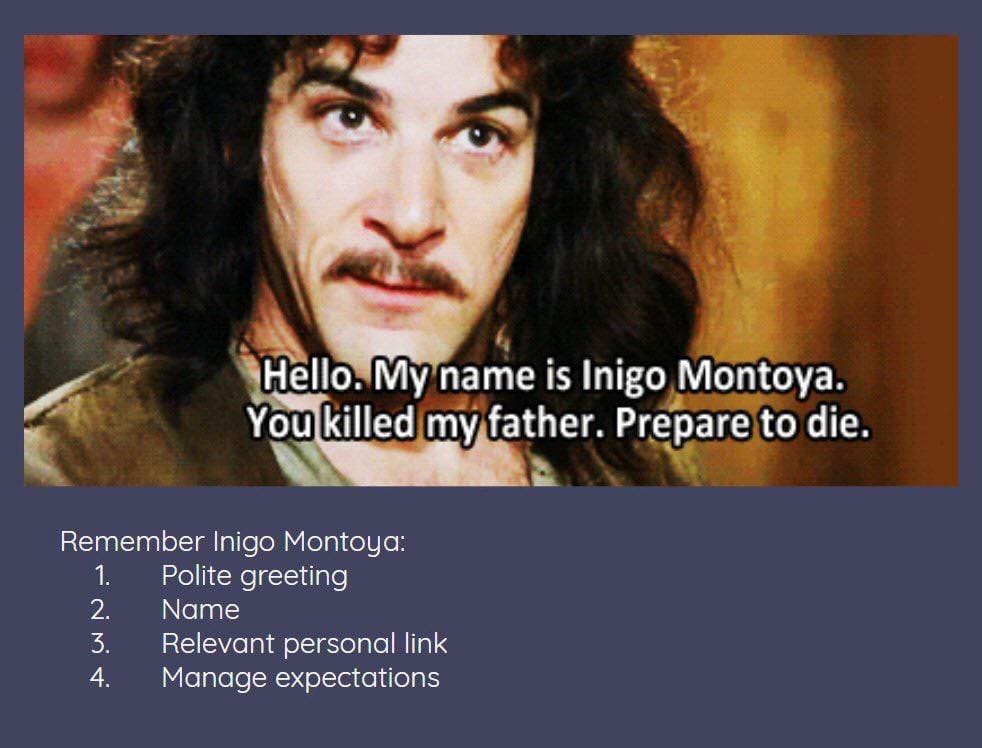

There are different stages in the contact process with a new client. First, you have to introduce yourself to the customer in a clear and polite way. My tip here is to use the Iñigo Montoya (the character from “The Princess Bride” movie) approach.

Polite salutation.

“Hello.”

Introduce yourself.

“My name is Iñigo Montoya.”

State your relationship.

“You killed my father.”

Clarify expectations.

“Prepare to die.”

Then, you have to listen actively to the customer, and understand their point of view and their internal thinking. Sometimes, as an FSE, we focus on solving the issue with the device, when really the customer is asking for advice or has another need.

During the soft skills training, we do a lot of role play with different kinds of customers and different situations. So, the FSE gets the opportunity to apply the previously learned theoretical skills.

Troubleshooting

What were the key skills you learnt for problem solving and troubleshooting whilst remaining and appearing calm? How do you pass this knowledge on to other engineers?

For me, one of the most important things that helps to stay calm during a complex problem, is prior preparation. If, the day before, you take a look at the job, read documentation about the issue, prepare all your tools and parts, then you will have confidence when you are in front of the device (and the anxious customer).

I always try to set a first plan of action, and then a B and C plan in case the first plan fails. And I go back through these plans during the drive to the customer. Time in the car provides you with quality thinking time before being in front of the customer. As well for new customers, I check on Google Maps for the location, parking places, even a restaurant for lunch time. All these things make you calm and less stressed when you walk into the customer and face the real challenge.

Challenges of training

What are the main challenges in your training role?

Scheduling training is the most complicated challenge. You need to take account of your schedule, the FSE schedule, room availability, and device availability. In addition, you even need to consider if a big show or exhibition in the city will make it difficult to book a hotel during the perfect week you have chosen.

How do you keep people’s attention throughout the session?

First, you must schedule a balance between theory and practice. Try not to have people sit for more than a couple of hours. Also, use examples from your experience; cases that have happened to you during your time in the field. As well make regular coffee and lunch breaks. Writing notes and drawing diagrams on a whiteboard is a more effective way of sharing knowledge than using a PowerPoint presentation. Always use a joke or funny video from time to time to break the monotony.

What are some ‘tools’ you use for when things are not being understood?

Drawing on the whiteboard and having some examples from a different field are my basic tools to ease understanding of difficult parts of the training.

How much do you learn from the engineers and technicians you are training?

A lot. We have trainees with different backgrounds and levels of expertise, so you always get a new and surprising view from them. Also, from time to time we have an FSE from Latin America and they provide me with a totally different perspective.

Typical week as medical Digitalisation Service Team Head

What exactly does your role as Digitalisation Service Team Head involve?

I manage a team of three people supporting the digital business of ZEISS in Spain and Portugal. I’m also responsible for supporting sales and marketing people in this field.

What are the goals of your role?

There are two main goals.

Firstly, to have an efficient team that provides top class support to our customers and colleagues.

Secondly, to make the transition to digital workflow easy for our customers.

What do you feel are the main positives of digitalisation?

Efficiency in the workflow, and use of new tools that makes the diagnosis and treatment of diseases safer and more reliable for doctors and patients. My view is that digitalisation is a game changer for this field: from different isolated devices that doctors need to link by themselves; to a streamlined workflow where information flows from different devices to create a better and bigger overview of the disease of the patient.

What are the negatives of digitalisation?

The main concern nowadays is cybersecurity. As the hospitals and clinics are more and more dependant on computer systems, they are more and more targets for criminals. Fortunately, cybersecurity is becoming a core priority in the management of hospitals, and IT teams are getting more proficient in cybersecurity.

Challenges after medical digitalisation

What are the main challenges after medical digitalisation facing the medical device industry over the next ten years?

Digitalisation is the challenge now, but the next step, AI, is getting closer. How to provide new and wonderful ways to automatically diagnose and treat with the use of Artificial Intelligence, while protecting privacy and reliability, will be the next challenge for the medical industry.

Further reading

Life as a field engineer working with Augmented Reality

How can Artificial Intelligence make Field Service Engineers more effective?

Responses